Hot Selling 500l 600l 800l 1000l Draft Beer Brewing Equipment Fermenter Bright Beer tank 1000l BBT

US $5,000.00-35,000.00 / set

1 set(s)Minimum order

processing:

Fermenting Equipment

place of origin:

Shandong, China

brand name:

TONSEN

processing types:

BEER

voltage:

220/380V or customized

power(w):

35kw

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | TONSEN |

| processing types | BEER |

| voltage | 220/380V or customized |

| power(w) | 35kw |

| weight | 3500 KG |

| warranty | 3 years |

| Machinery Capacity | 500L, 600L, 800L, 1000L |

| machinery test report | Provided |

| core components | motor, Pump, Pressure vessel |

| key selling points | High Productivity |

| video outgoing-inspection | Provided |

| Product Name | Beer Brewing Equipment |

| Material | SUS304/SUS316/red Copper |

| Brewhouse type | 2/3/4 vessels |

| Heating way | Electricity/Steam/Fire |

| Control way | PLC |

| Plate type | Mirror polishing/2B/wire Drawing |

| Insulation | Polyurethane/rockwool |

| QA & QC | YES |

| Cooling way | Dimple plate cooling |

| Supply capacity | 20 Set/Sets per month beer brewing equipment |

| After Warranty Service | Video technical support, Online support, Field maintenance and repair service |

| Local Service Location | Canada, United Kingdom, United States, France, Germany, Australia |

| After-sales Service Provided | Field installation, commissioning and training |

| Certification | ISO CE CIC |

| Applicable Industries | hotels, Food & Beverage Factory, Restaurant, Home Use, Food & Beverage Shops |

| Showroom Location | Canada, United Kingdom, United States, France, Germany, Australia |

| Condition | New |

| Warranty of core components | 3 years |

| Marketing Type | New Product 2020 |

Product Detail

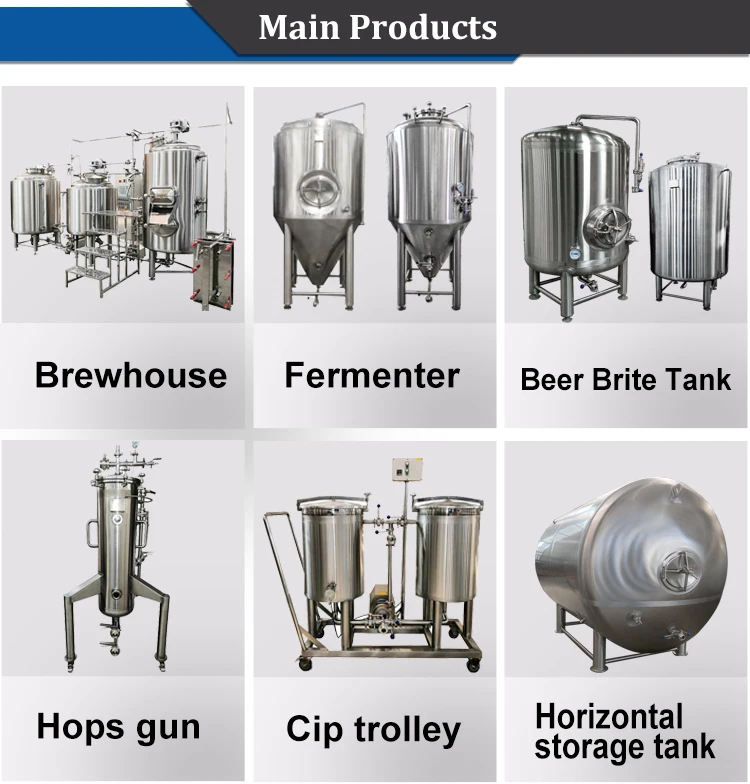

Hot selling 500l 600l 800l 1000l draft beer brewing equipment fermenter bright beer tank 1000l BBT

Product Description

Bright beer tanks are used to store beer.

These tanks are used for the storage of the beer prior to being served or packaged.

Depending on their application the beer serving tanks can be glycol jacketed or can be

located in a cold room.For brewpubs serving is often done by pumping or pressurizing the beer toward the serving location.

Main Features - Material

1. The material of the stainless steel 304.

Some factories are using 201 which is not food grade. And for a customer, it is not easy to test it.

Only when the 201 get rust, you will find it. But it is too late.

Now each batch of our steel plate will be randomly cut one part to be tested in our authoritative lab (government institute) and

have the certificate for the material.

Not only the steel plate (sheet) but also the valves, pipes, bolts, etc.

1. The material of the stainless steel 304.

Some factories are using 201 which is not food grade. And for a customer, it is not easy to test it.

Only when the 201 get rust, you will find it. But it is too late.

Now each batch of our steel plate will be randomly cut one part to be tested in our authoritative lab (government institute) and

have the certificate for the material.

Not only the steel plate (sheet) but also the valves, pipes, bolts, etc.

2. The thickness of stainless steel.

Most of the suppliers are quoting with 3mm interior shell and 2mm exterior shell. In fact, the real thickness is only 2.5mm and 1.5mm.

You may find the thinner sheet(plate) will easily distort after welding because of the high temperature.

3mm and 2.5mm, that is about 16% difference in weight. So this part is what customers can not test.

We have the stainless steel quality certificate and also we usually take the samples to test it from the government. We ensure its quality.

Most of the suppliers are quoting with 3mm interior shell and 2mm exterior shell. In fact, the real thickness is only 2.5mm and 1.5mm.

You may find the thinner sheet(plate) will easily distort after welding because of the high temperature.

3mm and 2.5mm, that is about 16% difference in weight. So this part is what customers can not test.

We have the stainless steel quality certificate and also we usually take the samples to test it from the government. We ensure its quality.

Detailed Information | ||||

Beer Equipment | SUS304 / SUS316 / red copper | |||

Interior | Stainless Steel | Thickness 3.0mm | ||

Exterior | Stainless Steel | Thickness 3.0mm | ||

Bottom Cone | 60° for fermentor | 160° for brewhouse | ||

Steam / Electrical heating | ||||

Glycol Cooling | ||||

Temperature Control | PT100 | |||

Pressure Display | Stainless Steel | Pressure Gauge | ||

Pressure Relie | Stainless Steel | Pressure Relief Valve | ||

Cleaning System | SUS 304 | CIP arm with 360 spary cleaning ball | ||

Insulation Layer | Rock Wool / Polyurethane | 70~80mm | ||

Manway | SUS 304 | Clamp or Flange Manway | ||

Sampling Valve | SUS 304 | Aseptic Type, no Dead Coner | ||

Dry Hops Adding Port | SUS 304 | Optional, clamp Type | ||

Carbonation Device | SUS 304 | Optional | ||

Yeast Adding Tank | SUS 304 | 5L | ||

Bright Beer Tank | SUS 304 | Single or Double-deck available | ||

Filling System | SUS 304 | Optional | ||

Freely design according to your craft, send inquiry now!

Packing & Delivery

Pre-sales service:

1)Help the clients to comfirm the configuration list.

2)Supplying different beer craft specification.

3)Desing the drawing according to the client's floor plan and your requirement.

4)Showing the detailed diagram of the tanks.

After sales service:

1)We provide turnkey system,onsite installation service for brewery projects.

2)It's avaliable for us to send engineers to guide install.

3)Online technology consult.

1)Help the clients to comfirm the configuration list.

2)Supplying different beer craft specification.

3)Desing the drawing according to the client's floor plan and your requirement.

4)Showing the detailed diagram of the tanks.

After sales service:

1)We provide turnkey system,onsite installation service for brewery projects.

2)It's avaliable for us to send engineers to guide install.

3)Online technology consult.

Company Profie

Pls feel free to contact me to get more informations!