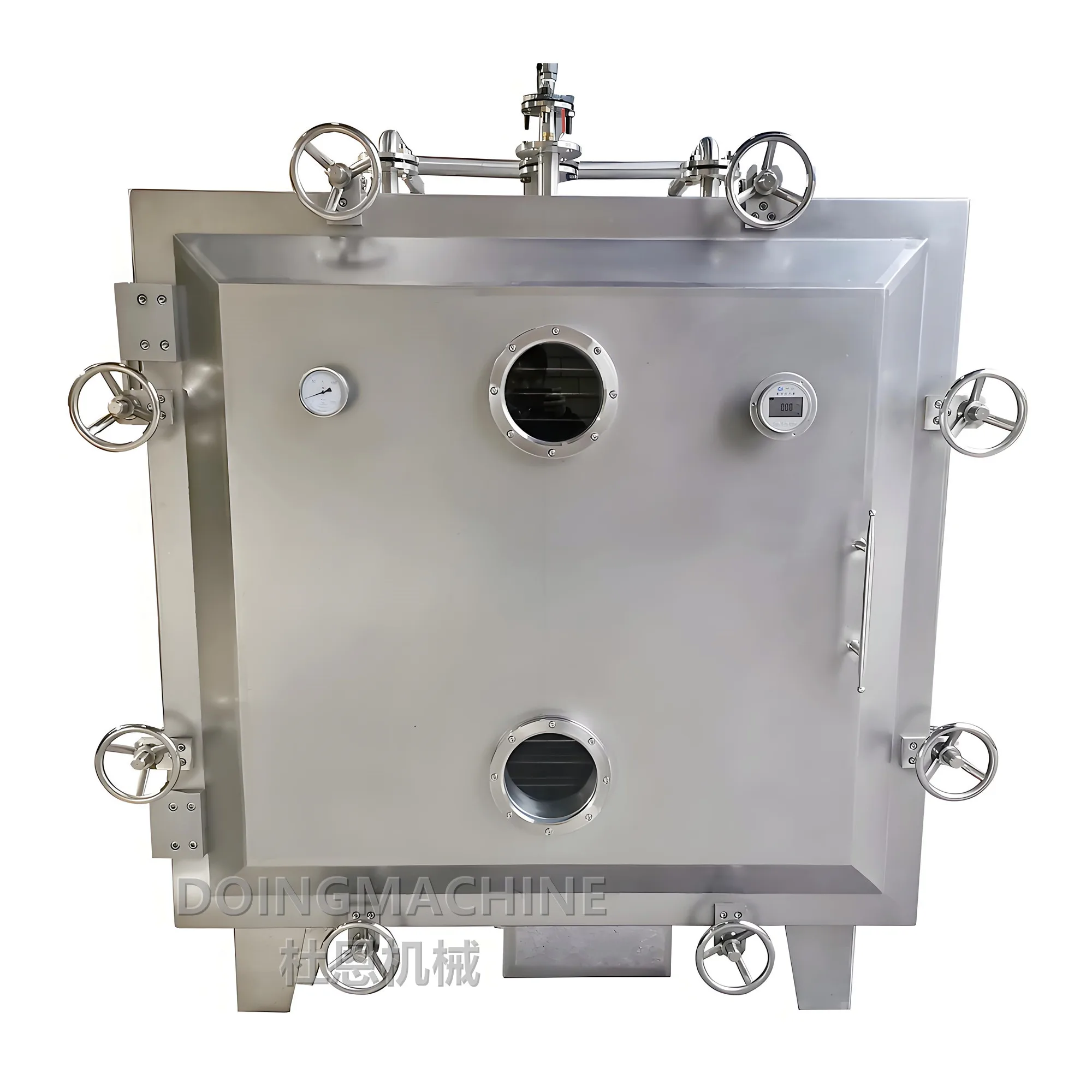

Industrial Vacuum Shelf Tray Dryer

1 set(s)Minimum order

type:

Vacuum Drying Equipment

Drying Capacity (kg):

50, 150, 200

application:

Chemicals Processing, Food Processing

place of origin:

Jiangsu, China

brand name:

Doing Machine

voltage:

380V/50HZ,3P

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| type | Vacuum Drying Equipment |

|---|---|

| Drying Capacity (kg) | 50, 150, 200 |

| application | Chemicals Processing, Food Processing |

| place of origin | Jiangsu, China |

| brand name | Doing Machine |

| voltage | 380V/50HZ,3P |

| power(w) | 2.2-7.5kw |

| dimension(l*w*h) | 2260*1200*2500MM |

| key selling points | Energy saving |

| warranty | 1 Year |

| weight (kg) | 2000 |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | Pressure vessel |

| heating method | Steam Heating |

| material | SUS304, SUS316L |

Product Detail

Product Description

1. Low temperature drying of powdery, granular and slurry materials under vacuum condition

2. Tray quantity: 20-384

3. Heat source: steam or hot water

4. cGMP design

2. Tray quantity: 20-384

3. Heat source: steam or hot water

4. cGMP design

Working principle & application:

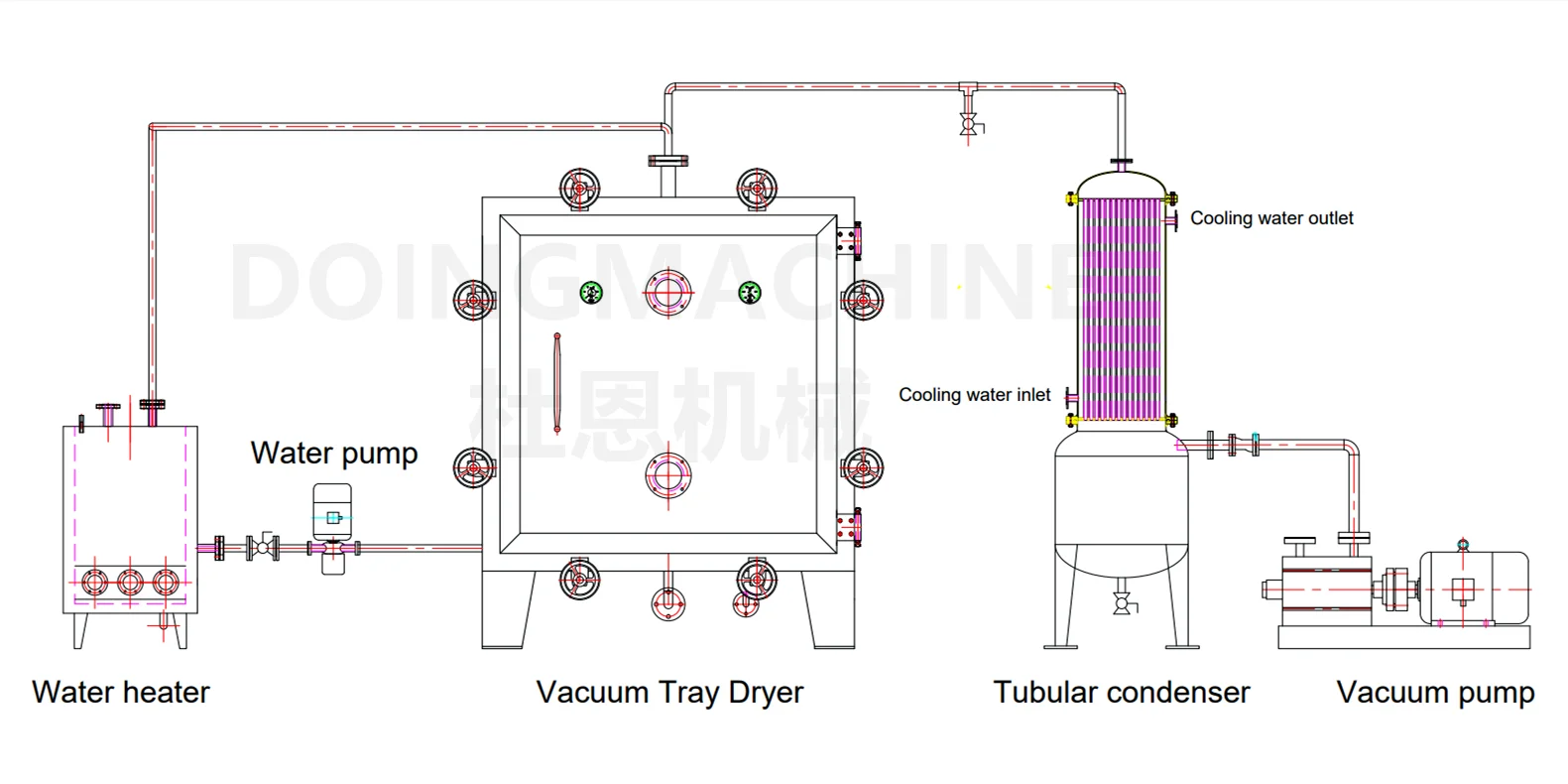

FZG Vacuum Tray Dryer (also called Vacuum Shelf Dryer, Vacuum Chamber Dryer) is the most commonly used static chamber dryer under vacuum condition. Inside the drying chamber, trays loaded with wet materials are placed on the drying shelf.

In drying process, heating medium, such as steam, hot water or thermal oil, is forced to circulate inside the drying shelf to transfer the heat to wet material. Under vacuum condition, the boiling point of water or solvent is much lower which makes low temperature drying highly effective.The vacuum pump constantly extracts the evaporated moisture as vapor to speed the drying process. Tubular condenser is equipped to recover the evaporated moisture.

FZG Vacuum Tray Dryer is good at drying various kinds of wet materials with low temperature:

1) Thick liquid, slurry, wet powder or granular wet materials;

2) Heat sensitive and/or oxygen-sensitive wet materials;

3) Moisture is solvents and needs to be recovered.

Technical advantages:

1) Compact design: The square vacuum chamber requires minimum installation and operation space.

2) Fast and uniform drying: The specially designed drying shelf can make sure heating medium evenly flow through each layer of shelf for uniform heating.

3) cGMP sanitary design: The vacuum chamber and trays are made by SUS304 or SUS316L stainless steel and mirror polished without blind angle for cleaning for cGMP sanitary standard.

4) Low-temperature drying: Vacuum can considerably lower the boiling point of moisture or solvent, which makes low-temperature drying highly effective and energy-saving.

2) Fast and uniform drying: The specially designed drying shelf can make sure heating medium evenly flow through each layer of shelf for uniform heating.

3) cGMP sanitary design: The vacuum chamber and trays are made by SUS304 or SUS316L stainless steel and mirror polished without blind angle for cleaning for cGMP sanitary standard.

4) Low-temperature drying: Vacuum can considerably lower the boiling point of moisture or solvent, which makes low-temperature drying highly effective and energy-saving.

Model | FZG-10 | FZG-15 | FZG-20 | FZG-30 |

Inner dimension (mm) | 1500x1060x1220 | 1500x1400x1220 | 2800x1800x1800 | 5600x1800x1800 |

External dimension (mm) | 1924x1720x1513 | 2060x15131924 | 3100x2000x2000 | 6000x2000x2000 |

Drying shelf layer | 5 | 8 | 16 | 16 |

Net space between shelf | 122 | 122 | 72 | 72 |

Tray size (mm) | 640x460x45 | 640x460x45 | 640x460x45 | 640x460x45 |

Tray quantity | 20 | 32 | 192 | 384 |

Vacuum degree (Mpa) | -0.08-0.092 | -0.08-0.092 | -0.08-0.092 | -0.08-0.092 |

Vacuum pump (KW) | 4 | 5.5 | 11 | 15 |

Gross weight (KG) | 1400 | 2100 | 4000 | 8000 |

Detailed Images

Chamber door hinge & tightening wheel

Fixed drying shelf

Removable drying shelf

Dismountable heating medium pipe

vacuum system

FZG-30 vacuum chamber

FAQ

Q: What information is needed in order to get a quotation?

A: Our Vacuum Tray Dryer is customized according to specific raw material, drying capacity and heat source etc. The following information is needed to work out a detailed quote:

1) Raw material name, bulk density, particle size, flowability etc. Samples might be needed for tests;

2) Initial moisture content; and target moisture content in dried product;

3) Required load capacity (input) in kg/batch;

2) Initial moisture content; and target moisture content in dried product;

3) Required load capacity (input) in kg/batch;

4) Suggested drying temperature;

5) Heating medium: steam, hot thermal oil or hot water;

6) Power supply type: 220V/380V/415V/440V, 50/60Hz, three phase;

Q: What is your normal lead time?

A: All our machines are customized. The normal lead time is 30-40 days after receiving the advance payment.

Q: How the machine is packed?

A: The machine is packed in standard plywood box.

A: The machine is packed in standard plywood box.

Q: What kind of after-sale service can you provide?

A:1) All our machines are fully tested before shipping. Detailed operation manual, which includes photos, installation & operation videos, layout drawings, electric drawings etc. is delivered with the machine. So the end-user can easily install and operate the machine.

2) In response to cutomer's invitation, technicians can be sent to the end-user's workshop for installation, commissioning and training.

3) Provide life-long technical consultation and favorable spare parts.