Lab 50L Stainless Steel Jacketed Bioreactor Automatic Grade Pressure Vessel Pump Motor Engine for High Temperature Reactions

US $3,800.00-4,100.00 / set

1 set(s)Minimum order

capacity:

100L

automatic grade:

Automatic

type:

bioreactor

video outgoing-inspection:

Provided

machinery test report:

Provided

core components:

PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| capacity | 100L |

|---|---|

| automatic grade | Automatic |

| type | bioreactor |

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| place of origin | China |

| voltage | 220V, 110V |

| power(w) | 1.5kw |

| dimension(l*w*h) | 690*690*2350mm |

| Warranty | 3 years |

| key selling points | Easy to Operate, Famous brand PLC, Remote Control, Remote Monitoring, Long Service Life, High Productivity, Accurate temperature control, Competitive Price, Low Noise Level, Patented Product, Multilayer, Multifunctional, Flexible Manufacturing, Famous brand motor, Eco-Friendly, Low Maintenance Cost, High Rigidity, Automatic, Energy saving, High Safety Level, High-accuracy, IoT, Digital |

| Weight (KG) | 100 |

| Kettle volume (L) | 100 |

| Inter-layer volume (L) | 20 |

| Voltage/frequency (V/Hz) | 220/50 |

| Reaction temperature (°C) | -120~260 |

| Achievable vacuum (MPA) | -0.098 |

| Stirring speed (rpm) | 0-460 |

| Power (w) | 200(1:3) |

| Material | SUS316L/SUS304 |

| Exhaust | 2 dm exhaust valve |

| Dropping hole | 50.5 chuck/1000ml funnel |

Product Detail

Products Description

The double-layer stainless steel reactor is designed with double-layer stainless steel. The inner layer can be put into the reaction solvent for stirring reaction, and the inter-layer can be connected with different cold and heat sources (refrigerating liquid, hot water or hot oil) for cyclic heating or cooling reaction. Under the condition of set constant temperature, the stirring reaction can be carried out under normal pressure or negative pressure according to the use requirements in the closed stainless steel reactor, and the reflux and distillation of the reaction solution can be done. It is an ideal pilot test and production equipment for modern fine chemical plants, biopharmaceuticals and new material synthesis.

Stainless steel reactors are usually combined with vacuum devices, high and low temperature devices, and peristaltic pumps to form a complete experimental unit.

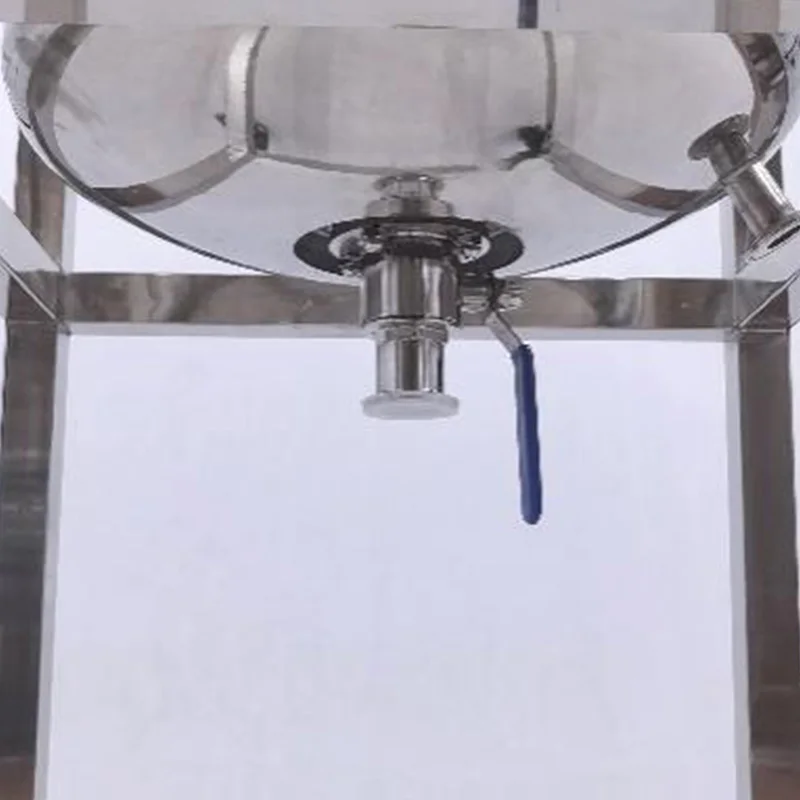

Details Images

Product Paramenters

Model | BSF-100L |

Dimensions (mm) | 690*690*2350 |

Kettle volume (L) | 100 |

Inter-layer volume (L) | ≈20 |

Voltage/frequency (V/Hz) | 220/50 |

Reaction temperature (°C) | -120~260 |

Achievable vacuum (MPA) | -0.098 |

Stirring speed (rpm) | 0-460 |

Power (w) | 200(1:3) |

Seal form | SUS304 ceramic composite mechanical seal |

Number of kettle cover ports | Eight ports (optional) |

Material | SUS316L/SUS304 |

Temperature measuring hole | 50.5 chuck/φ12 temperature measuring tube |

Dropping hole | 50.5 chuck/2000ml funnel |

Condensation hole | 50.5 chuck |

Return hole | 50.5 chuck/φ38 return port |

Sight glass | φ89 |

Feeding port | φ89 |

Pressure gauge | 50.5 chuck/± integrated pressure gauge |

Exhaust | 2 dm exhaust valve |

Stirring | SUS316L push-type stirring paddle |

Optional | Explosion-proof whole machine/ |

(additional fees apply) | electric heating/Total 316L/collection tank/ |

mobile frame /spraying PTFE | |

Other | It can be customized according to needs |

Product packaging

Company Profile

HENAN BEIFAN EQUIPMENT CO.,LTD.(BEIFAN EQUIP)is located in Zhengzhou City, Henan Province, China. Our company specializes in international export business of reaction equipment, distillation equipment, drying equipment, purification equipment, chemical machinery, laboratory equipment, analytical instruments, etc.

Our factory is located on Gongye Road, Shangjie District, Zhengzhou.Over the past 20 years, it has exported products to more than 100 countries in the world. Our products are sold to Asia, Africa, Antarctica, South America, North America, Europe, and Oceania.

Office

Factory

Certifications

FAQ

1. Are you manufacturer or trade company?

We are one of leading manufacturers in China, which focuses on designing, manufacturing and selling all kinds of powder grinding equipment including planetary ball mills, roll ball mills, stir ball mills, crushers, mixers and sieve shakers as well as accessories matched with machines.

2. What is your delivery time if I place an order?

We often have a great deal of regular machine models and accessories in stock available. If you want to order our regular items, it takes about 1-3 working days to finish packing and inspection, Generally speaking we can make shipment of regular order from our warehouse within 3-7 working days after payment is received.

3. What questions about requirements are required to provide to us if you inquiry about ball mills?

Answers:

* What material is needed to be grind? By wet or dry method?

* How many liters of material are required to be ground per batch?

* What is feed size (mm) of starting materials?

* What final particle size (μm or nm or meshes) is required by grinding?

* Is material allowed with metal impurity contamination while grinding?

4. Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

5. What’s your warranty?

One-year warranty period is provided.

6. What is MOQ (Minimum Order Quantity) of one order?

One set of machine or one piece of accessories (like ball mill jar and balls) are acceptable.