LIENM Customize BFS Filling and Sealing Machine BFS Liquid PVC Film Forming and Sealing Machine

US $300,000.00-800,000.00 / set

1 set(s)Minimum order

application:

Food, Chemical

packaging type:

Bottles

packaging material:

Wood

automatic grade:

Automatic

driven type:

Electric

Voltage:

220V 380V

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| application | Food, Chemical |

|---|---|

| packaging type | Bottles |

| packaging material | Wood |

| automatic grade | Automatic |

| driven type | Electric |

| Voltage | 220V 380V |

| place of origin | Guangdong, China |

| brand name | LIENM |

| dimension(l*w*h) | Contact us |

| warranty | 1 Year |

| key selling points | High Productivity |

| filling material | Water |

| filling accuracy | ±0.1% |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Pump, PLC |

| filling nozzle | 12 |

| After-sales Service Provided | Video technical support, Field installation, commissioning and training, Online support, Field maintenance and repair service |

| Product name | Cosmetic BFS Plastic Ampoule Filling machine |

| Function | bottle making, filling ,cutting |

| Suitable for | cosmetic and other field |

| material | Stainless Steel 304/316 |

| speed | 8500-9000 pieces/hour |

| Advantage | Automatic Working |

| Powe | 220V/380V |

| Control | PLC+ Touch Screen |

| plastic raw materials | polyethylene, polypropylene |

| accuracy | 99% |

| Weight | 2000 KG |

Product Detail

LIENM Customize Automatic BFS Filling And Sealing Machine BFS Liquid PVC Film Forming And Sealing Machine

Products Description

LIENM Automatic Plastic Ampoule Bottle Blow Fill Liquid Equipment 20ml Hyaluronic Acid Cosmetic Serum BFS Machine is the most advanced suppository filling and sealing machine in China. This machine is suitable for all kinds of materials, such as PVC/PE composite, PVC/LDPE composite. Can be filled liquid, essence water, hyaluronic acid, emulsion and so on.This machine adoptsPLC control, man-machine interface is easy to operate.

This machine stepless operation, one minute can cut 10-25 times.

Production process

1. Heat plastic granules and extrude it into plastic parison

2. Blowing in the blowing mould

3. Filling

4. Sealing

5. Cutting (other process)

Production process

1. Heat plastic granules and extrude it into plastic parison

2. Blowing in the blowing mould

3. Filling

4. Sealing

5. Cutting (other process)

Technical Parameter

products | aqueous solution, no precipitate, no foam (provide sample test) |

container volume | 5, 10, 20ml with insert layer mold |

Container shape | Rows of small containers |

mold chamber number | 30/5 version X 6 vials |

production capacity | 8500-9000 pieces/hour, ±10%, depending on the specific specifications of products and plastic particles. |

plastic raw materials | polyethylene, polypropylene |

filling error range | meet the requirements of GMP |

weight error range | ±0.2g(same batch of raw materials) |

container thickness error | ±0.1mm |

Contact us

Company Profile

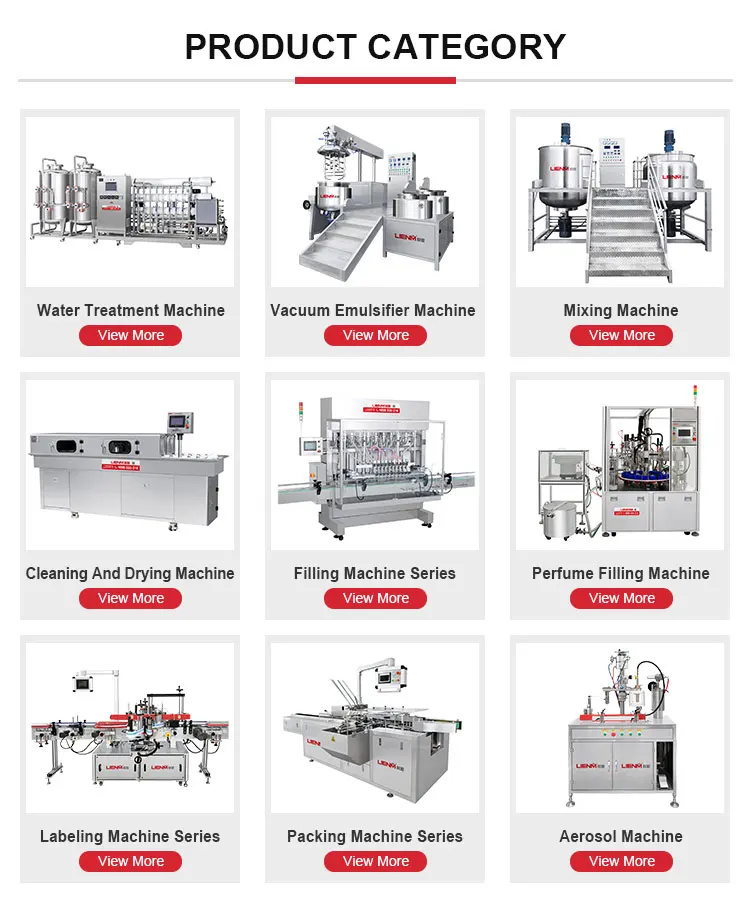

Recommend Products

FAQ