Small Complete Production Chocolate Paste Making Machine Double Jacket Heating Chocolate Grinding Mixing Tank Brazilian Protein

Other recommendations for your business

Contact us

Quik Detail

| mixer type | Belt mixers, homogenisers, paddles, stirrers, etc. |

|---|---|

| material processed | Chemicals, Food |

| range of spindle speed(r.p.m) | 0 - 3450 r.p.m |

| weight (kg) | 200 |

| material | SUS304, SUS316L |

| product type | Cosmetics, paints, perfumes, toothpaste, soaps, shampoos, etc. |

| additional capabilities | Milling |

| place of origin | China |

| brand name | QR Machine |

| voltage | 202-680V, 50/60Hz, customisable |

| dimension(l*w*h) | 50*50*70, capacity dependent |

| Power (kW) | 0.37~55kw, Related to capacity |

| warranty | 1 Year |

| key selling points | Competitive Price |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, Gear, Gearbox, Pump, Bearing, Engine, Mixing vessel |

| Capacity | 50-50000L, customized as required |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Motor Brand | ABB, Siemens, domestic brands, etc. |

| Jacket | Cooling and heating jacket avaible |

| Heating method | Electric/ Steam |

| Thickness | 2-8mm |

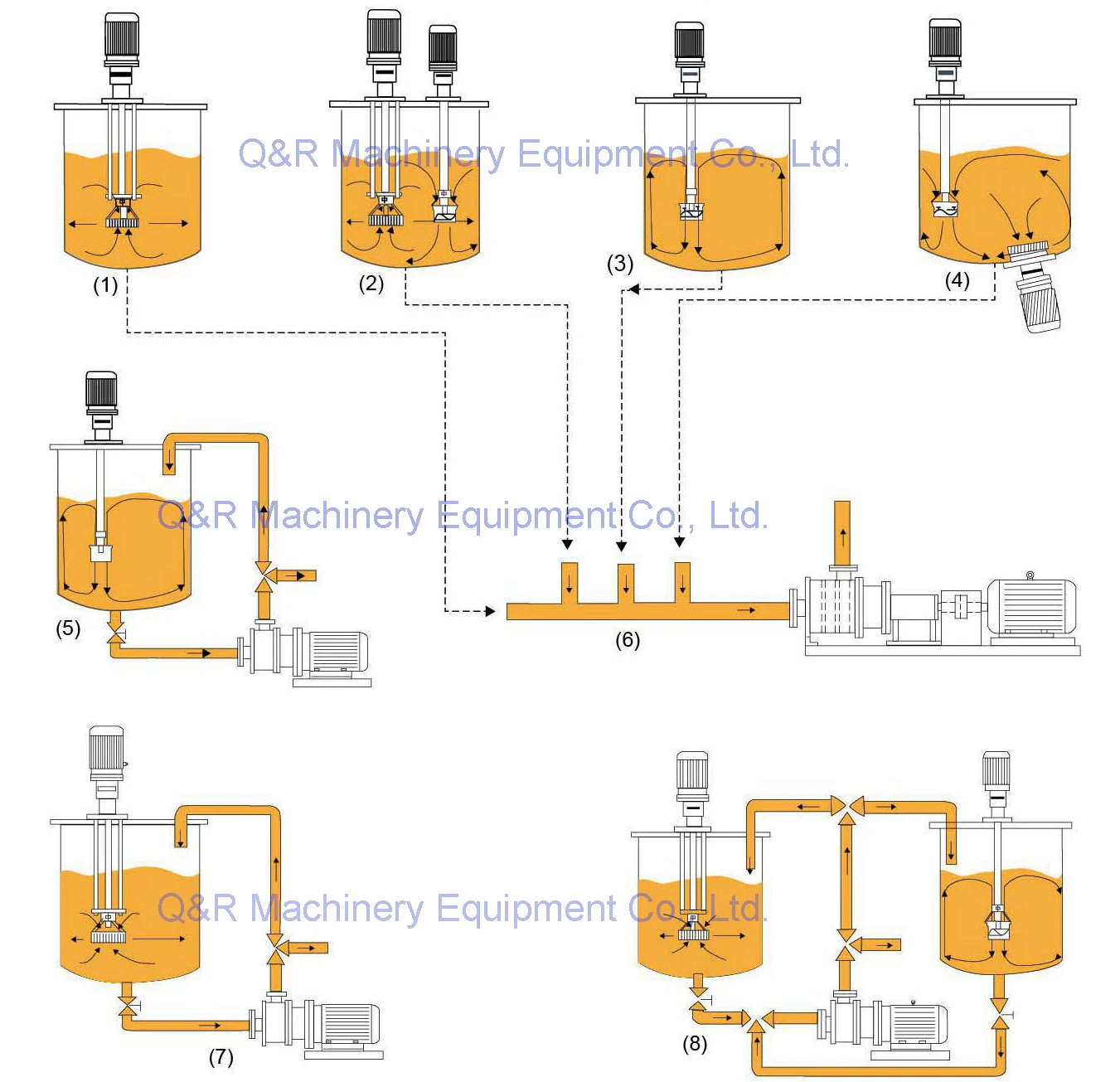

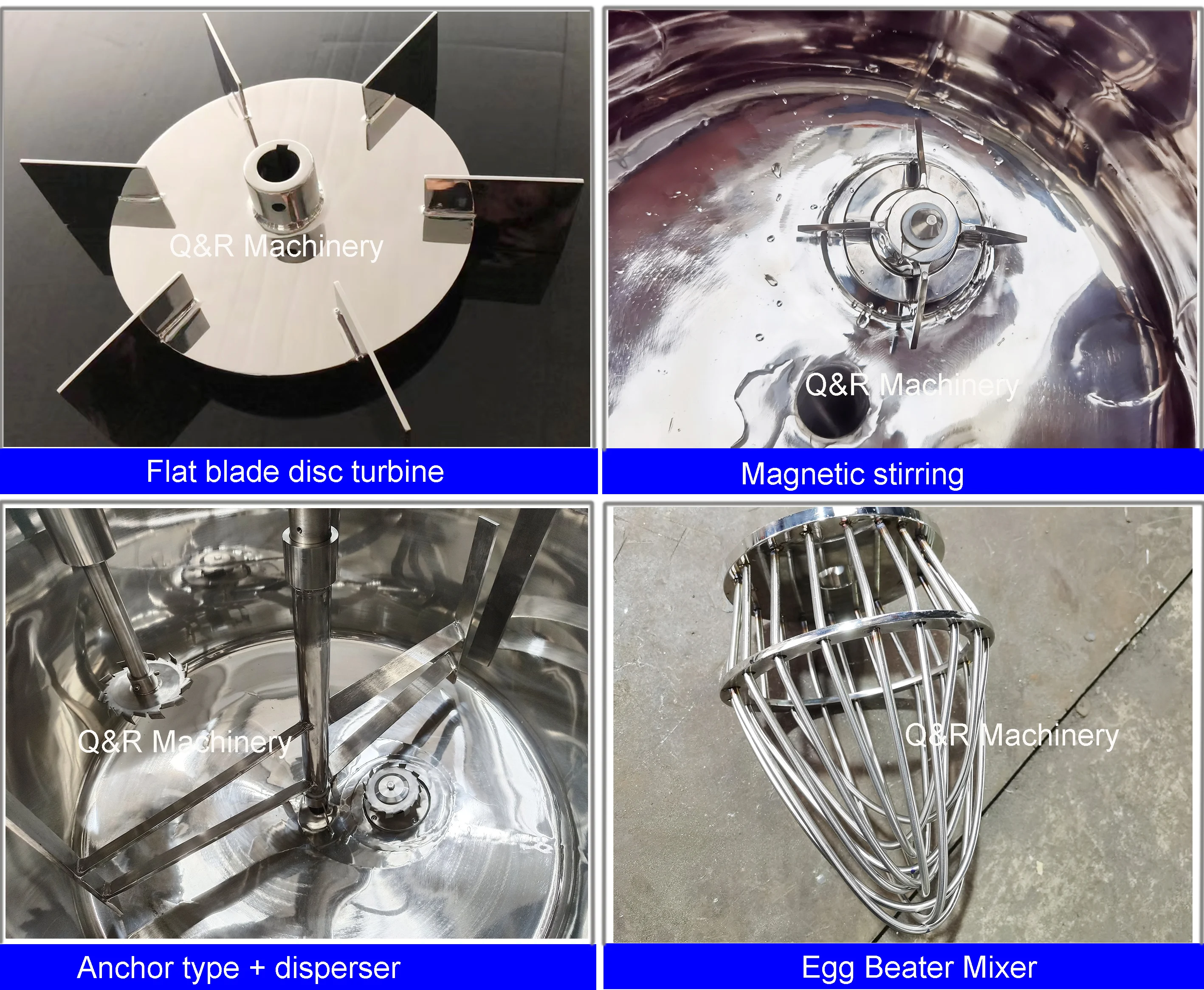

| Mixer type | Agitator,homogenizer,paddle,frame,anchor,scraper with stirrer |

| Usage | Cream,dairy,osmetic,beverage,chemical, etc. |

| Application | Chemical processing, food processing, viscous fluids, gels, Liquid with Suspended Solids |

| Value-added services | Online support, video technical support |

| Motor power | 0.37KW~55KW |

Product Detail

Stainless steel food grade Dissolving heating agitation tanks, widely used in beverage, food, dairy, Chemical and processing industries as dissolving Heating mixing tanks, buffer tanks, SUS316l aroma making equipment Melting tanks, High shear agitation tanks and Vacuum emulsifying tanks, which can be cleaned in accordance with hygienic standards. | ||||

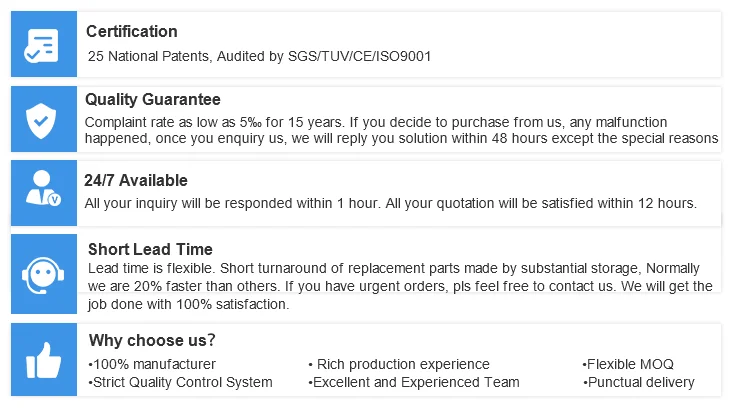

Product Features: 1) Material: SUS304/ SUS 316L 2) Layer : Single layer/ double layers/ three layers 3) Power : 0.37~55KW 4) Capacity : Top: flate top with lid / closed cover 5) Voltage: Polish: mirror polish inside and outside 6) Heating Type: electric/ steam heating | Advantages: 1) Certificates: CE ,ISO, 3A 2) Warranty : 12 months 3) OEM/ODM:can design, exploitation and manufacture by CAD software and drawing. 4) Testing&QC: pressure test and material test | |||

Factory Scale: 1) Located in: Zhejiang, China 2) Factory Area: 5000SQ.M 3) Employees: 37 4) Production Ability : 100 Pieces/SUS316l perfume making equipment mixing tank | Delivery Time: 1) Material Preparation Time: 2 days 2) Metal Processing Time: 7-10 days, based on actrual quantity 3) Test & Packaging Time: 1 day | |||

Yes, we are. Welcome to visit our factory.

2:Can you change the machine voltage as our request?

Yes, we can.

3: How about the delivery time?

With the standard products delivery time will be15-35 days after we receive your payment.

4: What's the payment terms?

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

5: Where are the main markets for your products?

Products have been exported to all over the world, especially in Northern Europe Western Europe, Eastern Europe North American,South American, Middle East, South Asia, Eastern Asia, African and etc.