Long Service Life Pilot Brewery Beer Brewing System Price for Home Using

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | Micet |

| processing types | Beer |

| voltage | 110-415V |

| power(w) | 50-5000Kw |

| dimension(l*w*h) | Capacity Request |

| weight | 2000 KG |

| warranty | 3 years |

| Machinery Capacity | 50l, 100L, 200L, 300L, 400L, 500L, 600L, 700L, 800L, 1000L, 1200L, 1500L, 1800L, 2000L, 2500L, 3000L, 3500L, 4000L, 5000L, 10000L, 20000L, 50000L |

| machinery test report | Provided |

| core components | Gearbox, motor, Gear, Pump, PLC |

| key selling points | Long Service Life |

| video outgoing-inspection | Provided |

| Product Name | Long Service Life Nano Brewery Beer Brewing System Price |

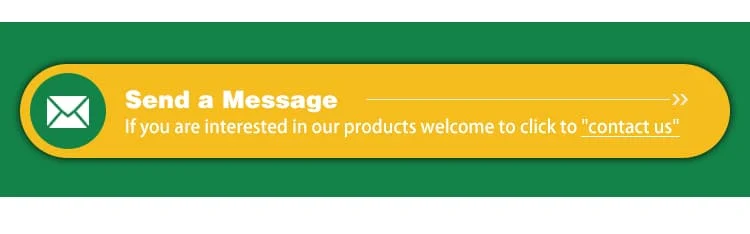

| Brewhouse Type | 2 or 3 or 4 vessels |

| Capacity | 100L-20000L |

| Heating Method | Steam/Electric/Direct Fire Heating |

| Control system | PLC Simens or PID Schneider/ABB brand |

| Application | Brewpub, Restaurant, Brewing Plant, Commecial |

| Material | SUS304/SUS316/red Copper |

| Power | 15-70Kw Depends On The Size |

| Work Pressure | Inner Jacket 0.4MPa; Cooling Jacket 0.5Mpa |

| Design Pressure | Inner Jacket 0.2MPa; Cooling Jacket 0.3Mpa |

| Applicable Industries | hotels, Food & Beverage Factory, Farms, Restaurant, Home Use, Food Shop, Energy & Mining, Food & Beverage Shops |

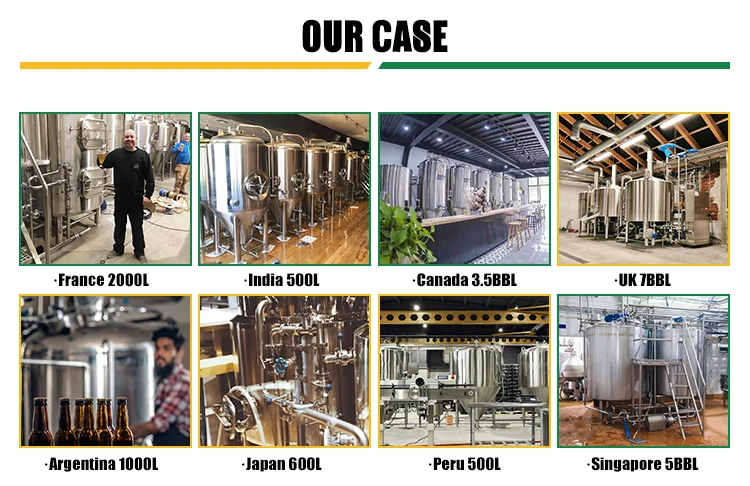

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Japan, Malaysia, Australia |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | New Product 2020 |

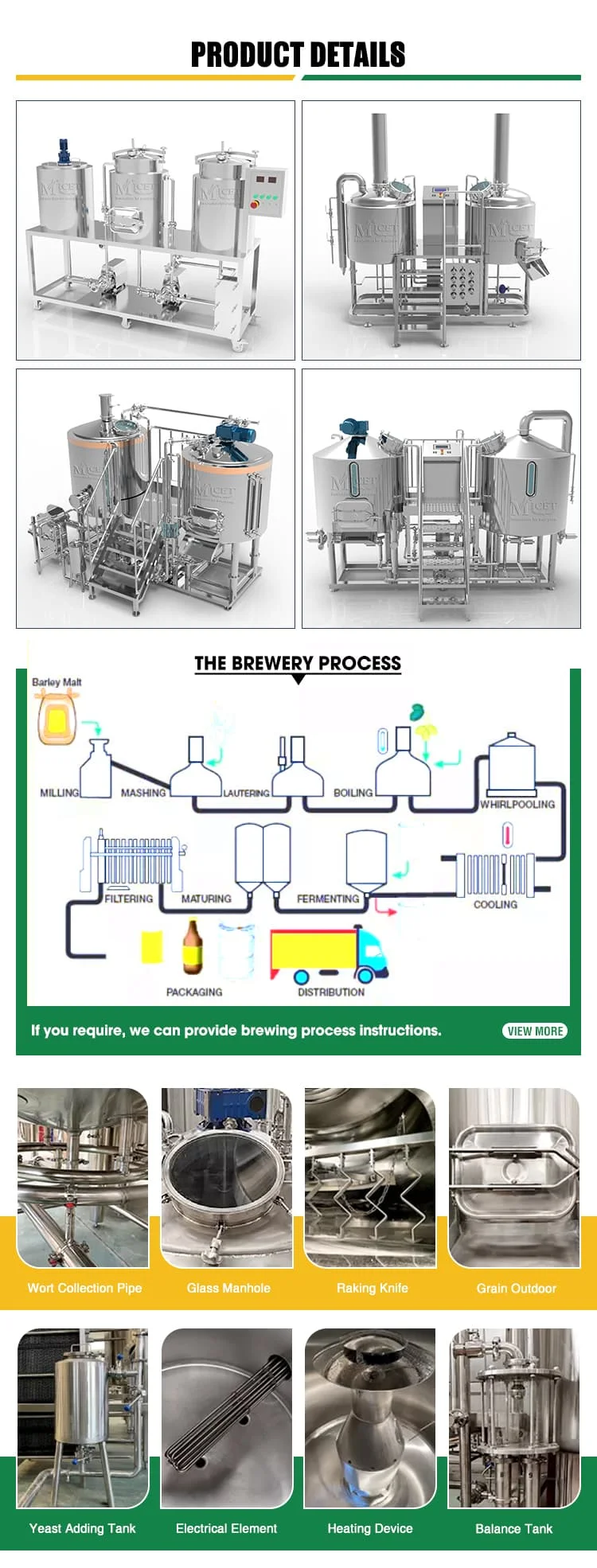

Product Detail

Output/ Brew | 500L | 800L | 1000L | 1500L | 2000L | 2500L | 3000L | 5000L | |||||||

Brew/Week | 2~6 | ||||||||||||||

Output/Week | 10~30HL | 16~48HL | 20~60HL | 30~90HL | 40~120HL | 150~300HL | 180~360HL | 240~360HL | |||||||

Area Request | >45㎡ | >60㎡ | >70㎡ | >90㎡ | >120㎡ | >140㎡ | >150㎡ | >180㎡ | |||||||

Brew master | 1 | 1 | 1~2 | 1~2 | 2~3 | 2~3 | 3~5 | 3~5 | |||||||

Material | Interior Shell: SUS304 TH=3mm; Exterior Shell:SUS304 TH=2mm /red copper | ||||||||||||||

Heating | Electric/Steam/Direct fire for optional | ||||||||||||||

Voltage | 3 phase/380(220, 415,440...)v/50 (60)Hz | ||||||||||||||

2. Milling sieve plate,wedge-shaped gap 0.7mm, 4mm thickness, can be disassembled and cleaned, and the bottom is supported and fixed.

3. Lauter tun is equipped with dustpan, which is convenient for grains out and cleaning.

4. Lauter tun stirring motor is equipped with frequency converter, which can adjust the speed, rake can be lifted up and down.

5. Brew kettle is equipped with an indoor steam condenseror outdoor exhaust chimney depends on customer

6. Equipping with a special inline hop filter to make the wort clearer before fermenting.

7. The pumpand motor use ABB or JLEM American brand, long service life, and low sound.

8. Brewhouse piping design is equipped with a cold and hot water mixing device, thermometer, and flow meter, which can evenly mix the cold and hot water before mashing.

9. The bottom of lauter tun is equipped with wort collection loop and under-the-flush device.

10. Equipping with wort balance tank to check the clarity of wort and protect the sieve plate.

11. Equipping with sparge arm and double CIP cleaning loop on top of the tank.

12. The HLT was designed with return port, CIP cleaning port, and water inlet, which can realize the recovery and utilization of hot water between the heat exchanger.

13. The working platform adopts water leakage and a non-slip design.

14. Brewhouse manways always use full glass manway.

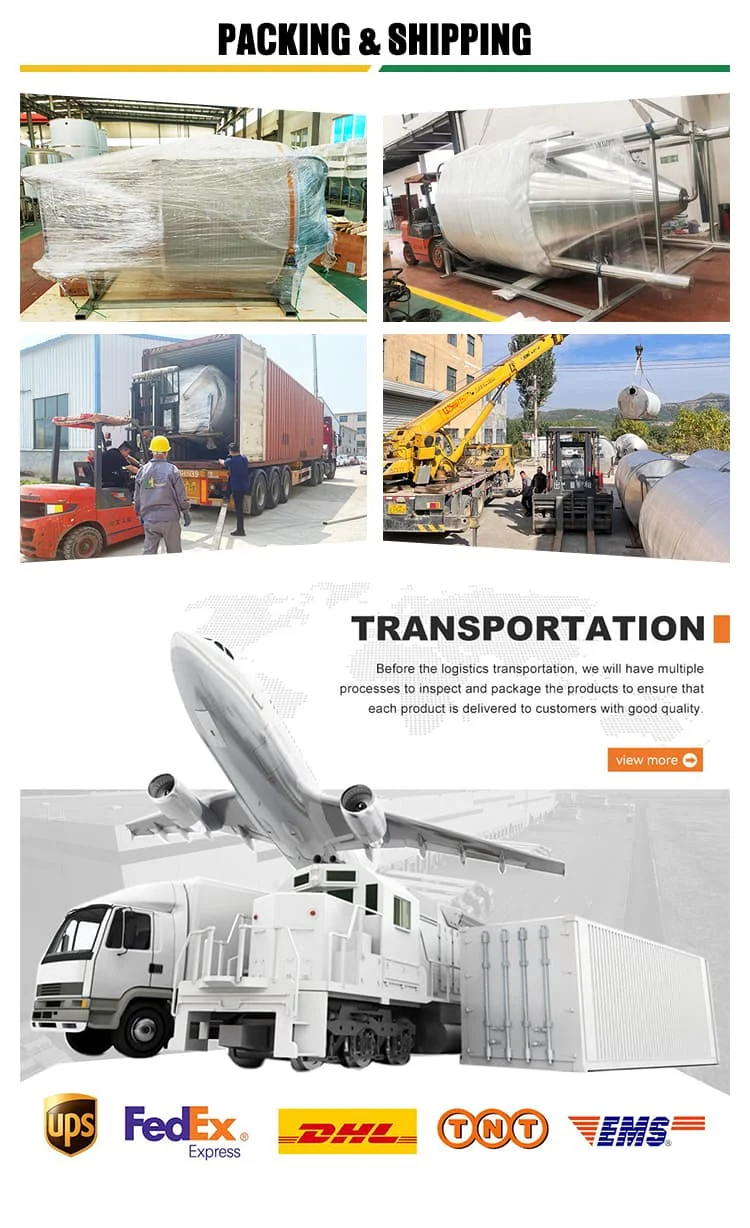

3. Each of our ports will have a lid in case the dust goes inside during shipping. For packing, the stand tank will be fully packed in case of any salt corrosion on the sea, for horizontal tanks, tanks will be packed by a steel frame on the skid and the legs will be fixed by a thread in case of any moving during transportation.

3. Micet factory marks all piping with numbers, solve any questions during your installation.

4. Micet technicians will train the brewer to produce qualified craft beer.

5. Micet provides installation and maintenance manual book, piping installing layout.

6. Sales&engineers could be keeping 24 hours online for service.

7. Micet provides a 3-year warranty on tanks sold with manufacturing defects from the factory. Micet provides a 1-year warranty on tank accessories, pumps, electronic components.

8. Any extra spare parts required, send and deliver immediately.

Micet will have at least 4 times inspections for each order, including materials come inspection, production process control, finished production inspection, and full line testing and inspection before shipping to ensure the final product will meet the client's requirements.

How to choose brewhouse equipment?

Brewhouse system selection for purchasing beer equipment there are about basically four types including 2 vessel brewhouse, 3 vessel brewhouse, and 4 vessel brewhouse. The combination type can be chosen depending on the client's budget, space size, local brewing process. We will also recommend according to old clients' experiences and different country brewing features.

How long is the delivery time?

1. The manufacturing time is 40 working days and will be enforced as soon as receiving the deposit.

What is your payment term?

1. T/T transfer, 40% advance payment for start production, after paying 60% balance payment for shipping. 2. Paypal or trade assurance is available.

Main machine guarantee for three years we'll provide free repairing. If anywhere goes wrong during. During this period accessories and electronic components will have a one-year free warranty. Anything is broken during the warranty. The replacements will be sent immediately and get within. Provide daily maintenance and technical services.