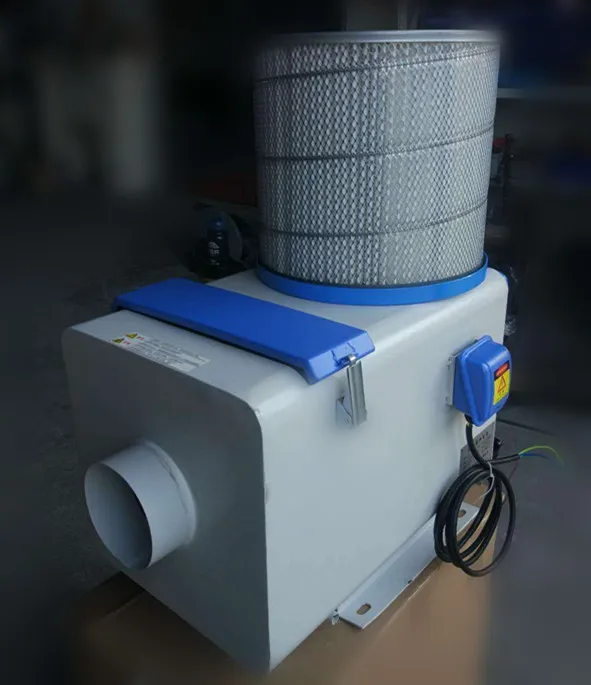

Mazak 5 Axis Cnc Milling Machine Industrial Centrifugal Oil Mist Collector Filter Extractors

Other recommendations for your business

Contact us

Quik Detail

| condition | New |

|---|---|

| place of origin | Guangdong, China |

| brand name | GENOR |

| warranty | 2 years |

| Product name | Oil Mist Purifier Collector |

| Power Source | Electrical |

| Motor power | 0.5kw to 2.2kw |

| Voltage | 220V , 380V, 400V ,415V,480V |

| Frequency | 50Hz or 60Hz |

| Material | Corrosion protection shell |

| Filter type | HEPA filter |

| Application | CNC machines and related equipments |

| Certification | CE and ISO |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Energy & Mining |

| After Warranty Service | Video technical support, Spare parts |

| Local Service Location | None |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Hot Product 2019 |

| Warranty of core components | 2 years |

| Core Components | motor |

| After-sales Service Provided | Free spare parts |

Product Detail

mazak 5 axis cnc milling machine Industrial Centrifugal Oil Mist Collector Filter Extractors

The oil mist collector is a purification device designed for various types of processing machine tools .It uses centrifugal separation and high-efficiency filtration technology.

The oil mist exhaust gas is sucked into the purification equipment under the suction of the impeller. Firstly, it passes through the split cone and enters the first-stage filtration device to remove oil mist particles over 20 Ym .

Then enters the centrifugal separation system. Strong centrifugal force generated when the impeller rotates at high speed causes oil mist particles over 3Ym to separate from the exhaust gas and flow back into the oil pan.

Finally, the drawn air enters a high-efficiency filter to filter out 0.3Ym oil mist particles.

After the exhaust gas is treated by the oil mist purification system, the oil mist exhaust gas is effectively collected and purified, and the collection and purification efficiency is as high as 99% or more.

| Model | GFT500 | GFT750 | GFT1500 | GFT2200 |

| Voltage | 50 / 60Hz , 3phase , 120V, 220V, 380V,400V ,415V | |||

| Power(kw) | 0.5 | 0.75 | 1.5 | 2.2 |

| Air Volume(m3/h) | 500 | 800 | 1200 | 1500 |

| Air pressure(pa) | 1100 | 1200 | 1800 | 1800 |

| Noise(Db) | 58 | 65 | 68 | 68 |

| Capture efficiency | 99.97% | |||

| Suction diameter(mm) | Φ98 | Φ123 | Φ148 | Φ198 |

| Dimensions(L*W*H)mm | 650*390*500 | 710*430*530 | 860*450*550 | 910*530*640 |

Application :

The oil mist purifier is a purification device designed for various types of processing machine tools.

It is widely used in CNC lathes, washing machines, cylindrical grinding machines, internal cylindrical grinding machines, and surface grinding machines. hobbing, milling and edging machine tools, vacuum pumps, spray test chambers, electric discharge machining, CNC machined machining centers and other processing equipment produced in the oil mist, with high purification efficiency, low noise, easy use .

Advantages of installing oil mist purifier

1.The oil mist produced by the machines has adverse effects on the human body's respiratory system and skin health, and will reduce the work efficiency of employees , long-term work in this environment, the probability of occupational disease is high .

2. If oil mist diffuse in the air for a long time , it will lead to failure of the machine's circuit system and control system, increase maintenance costs;

3. The oil mist purifier can recycle the cutting fluid of the machine tool and reduce its loss.

FOR MORE DETAILS AND QUOTES, CONTACT US!