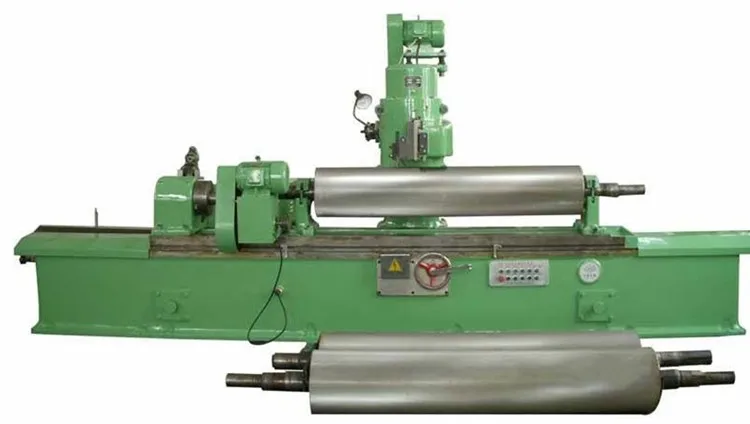

MDDK 25*1000mmRoller Mill Fluting and Grinding Machine for Buhler Roller Miller

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Henan, China |

|---|---|

| brand name | CTGRAIN |

| production capacity | Depend |

| voltage | 220V/380V |

| power(w) | depend |

| weight | KG |

| dimension(l*w*h) | 5200x1600x2270mm |

| warranty | 1 Year |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| key selling points | Low Maintenance Cost |

| Name | Grinding rolls fluting machine |

| Roller Diameter | 150-400mm |

| Max. Roller Length | 600-1500mm |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Teeth Number | 150-1200 per circle |

| Application | rollers processing |

| Type | FMLY Series |

| Spiral of corrugation | <16:100 |

| Working pressure and speed | with hydraulic pump |

| Function | Polishing and fluting |

| Applicable Industries | Food & Beverage Factory |

| Showroom Location | None |

| Condition | New |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

Product Detail

Serve 21 countries and75 flour mills

Industry leading processingequipment and process

Strong design capability forcomplete sets of equipment

The special machine to grind and flute rollers

* Widely used in Flour Mill, Oil Mill, Feed Mill, Corn Mill and so on

Features

1) Inclined guide equipped with driving system for up-and-down move, easy operation and convenient for angle adjusting.

2) Driven by hydraulic system.

3) Composite rail can ensure running stably and high precision.

Type | Roller Diameter | Teeth Number | Max. Roller Length | Spiral of corrugation | Weight | Shape Size |

mm | mm | kg | mm | |||

FMLY630 | 180-250 | 150-1200 per circle | 600 | ≤16:100 | 1700 | 2730x1210x1360 |

FMLY800 | 200-300 | 150-1200 per circle | 800 | ≤16:100 | 3200 | 2890x1485x1310 |

FMLY1000 | 200-300 | 150-1200 per circle | 1000 | ≤16:100 | 3800 | 3150x1400x1500 |

FMLY1250 | 230-350 | 150-1200 per circle | 1250 | ≤16:100 | 5000 | 4050x1447x1520 |

FMLY1500 | 150-400 | 150-1200 per circle | 1500 | ≤16:100 | 5200 | 4300x1600x2270 |

Grinding Part

Fluting Part

The company focuses on technology reformation, improving the manufacturing ability and quality of machine. The company took the lead in the introduction of CNC laser cutting machine, CNC bending machine, CNC lathes and other advanced processing equipment.

At the same time purchased CNC machining center, CNC boring machine, CNC lathe, CNC milling machine,surface grinder, planing machine and other advanced processing equipment investment, and added electrostatic spraying production line. The product quality can be promised by these reliable manufacturing equipment support.

Our company adopt steel plate laser cutting machine, CNC bending machine, carbon dioxide arc welding and argon arc welding, welding scale, rotary automatic welding, electrostatic spraying surface treatment, continuous improvement and innovative models. Our products are not only has good performance, but also easy for installation and maintenance with low cost. The product with advanced technology, reliable quality, and nice appearance has been appreciated by many clients.

Project installation: we have professional electrical and mechanical project installation team. The display of the equipment is neat, reasonable, beautiful, generous, and easy maintenance.

The commissioning is carried out under the guidance of experienced experts and professors on the spot. The test can be successful by one time commissioning, and can totally meet or exceed the design specifications and requirements.

Our machinery are widely used in many domestic users. And our turn-key projects and single equipment were exported to Thailand, Burma, Australia, Sri Lanka, Italy, Germany, Chile, Argentina, Brazil, Ukraine and other more than 20 countries and regions. Many clients around the world have visited our company on business.We warmly welcome clients and supplied excellent solutions with best quality equipment and technical services, and we received high recognition from them.

The company has a strong technical force, with more than 20 engineers and technicians who are specialized in flour, electric, automatic control computer and so on.The products have passed ISO9001:2000 international quality management system, European Union CE quality certification and other international quality management system certification.It also has obtained Henan Province Science and Technology Type Sme Certification , National High-tech Enterprise Certification and 7 national invention patent certificates.The company can provide a turn-key project design, including the flowchart drawing design, electrical and automatic control design, architectural planning a.These designs all get CAD computer aided design. Detailed drawing materials, advanced tool and rapid design can supply the client the best choice.

1.Q: Are you the manufacturer?

A :Yes, We are a professional flour milling machine manufacturers.

2.Q :Will you help to install the machines?

A :Yes, our engineers can indicate installation,test running, and training local operators. Engineers available to service machinery overseas after-sales Service

3.Q : Do you accept small order?

A : Yes,We accept small order , the MOQ is 1.

4.Q: How do I make payment for my order?

A: You make payment by taking the proforma invoice and our bank details,you can use T/T(bank transfer) and L/C to finish the payment.

5.Q: What's the warranty time?

A: Our warranty time is 12 months, so you can trust us and the quality of our machine.

Hot Selling FMLY Series Grinding rolls fluting machine