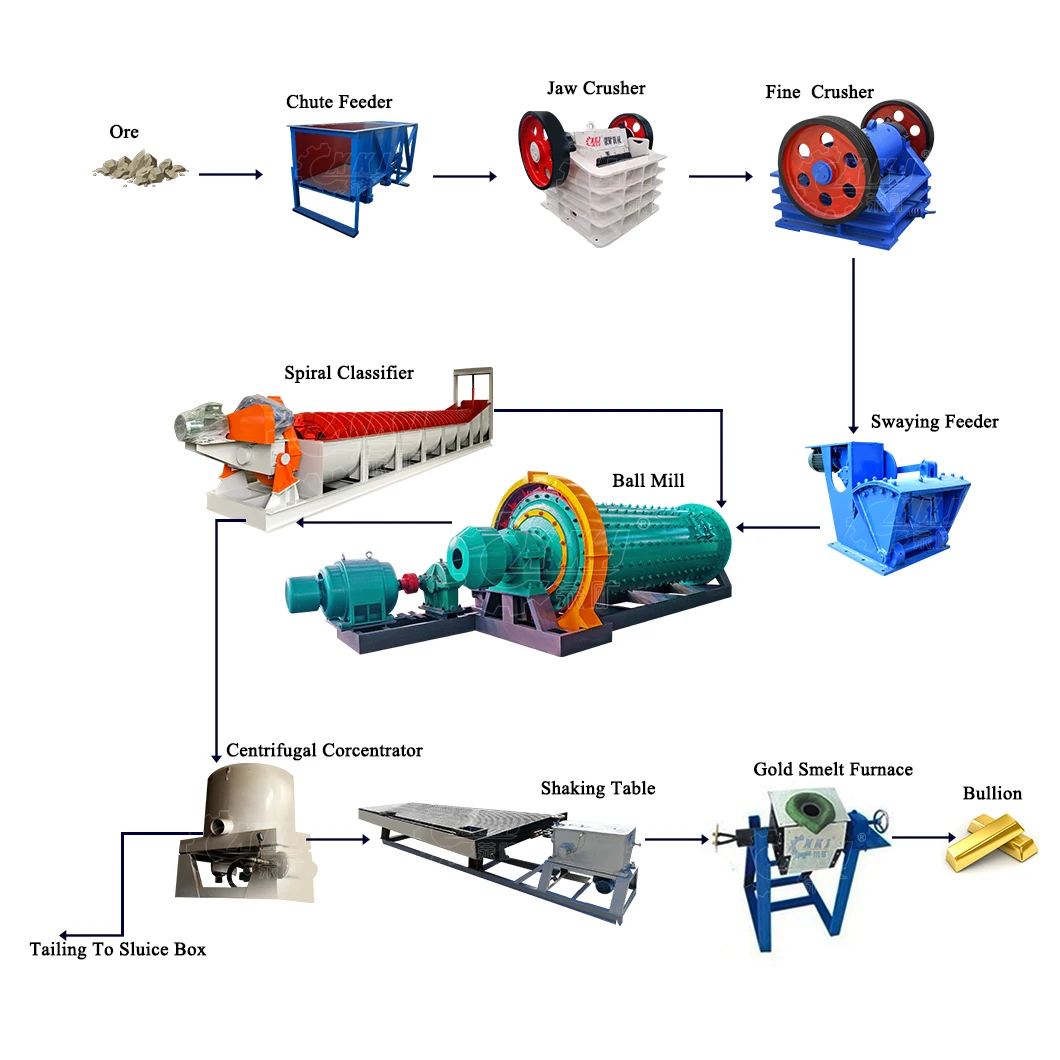

Mineral Mining Gold Ore Stone Grinding Ball Mill Machine With Rubber Liner or High Manganese Steel Liner Price Rotary Ball Mill

Other recommendations for your business

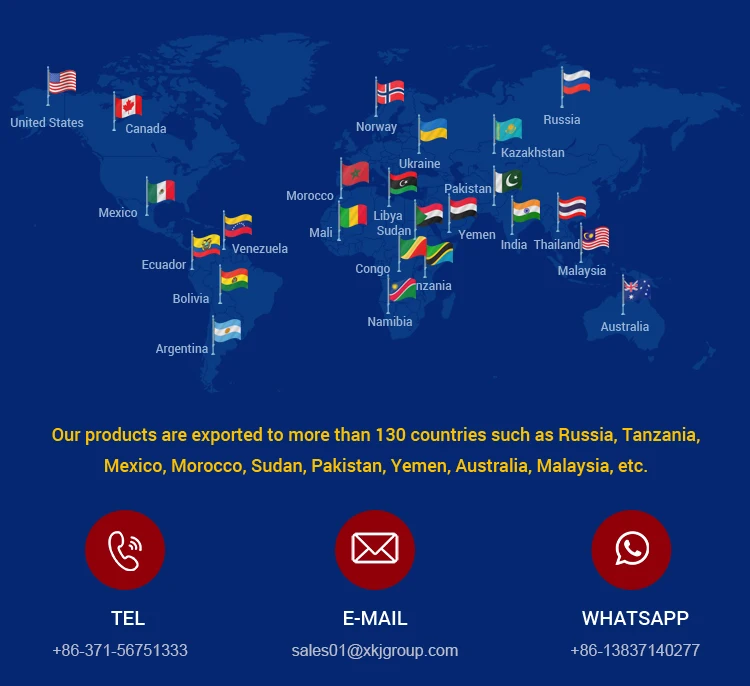

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | According to model |

| Place of Origin | Henan, China |

| Brand Name | XKJ |

| Dimension(L*W*H) | According to model |

| Weight | 10 KG |

| Warranty | 12 Months |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Application | Ball Mill |

| Feeding size | 0-25mm |

| Discharing size | 0.074-0.6mm |

| Spare parts supplying | Life Long Provide |

| Installation | Engineer's Guide |

| Delivery | 25-30 days |

| Color | Customerized |

| Product name | Gold Ore Grinding Machine |

| After sale service | Life-long Service |

| Showroom Location | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Nigeria, Uzbekistan, Tajikistan, Japan, Malaysia, Australia |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining, Other, Gold Ore Stone |

Product Detail

Model | Cylinder RPM (r/min) | Ball load (t) | Feeding size (mm) | Discharging size (mm) | Capacity (h) | Dimension (LxWxH) (mm) | Weight (t) |

MQG 600x1800 | 45.5 | 0.5 | ≤ 10 | 0.074-0.5 | 0.2-0.5 | 3100x1624x1070 | 2.5 |

MQG 900x1800 | 38 | 18 | ≤ 20 | 0.074-0.6 | 0.8-2 | 4196x2300x1985 | 5.8 |

MQG 900x3000 | 374 | 2.7 | ≤ 20 | 0.074-0.3 | 0.8-3 | 6170x2034x2074 | 7.5 |

MQG 1200x2400 | 32 | 4.8 | ≤ 25 | 0.074-0.6 | 1.5-4 | 6520x2850x2540 | 9.8 |

MQG 1200x4500 | 30 | 5.2 | ≤ 25 | 0.074-o.6 | 1.5-6 | 8820x3070x2630 | 13.2 |

MQG 1300x4000 | 36 | 5.8 | ≤ 25 | 0.074-0.6 | 2-6 | 7661x2720x2100 | 14.8 |

MQG 1500x3500 | 28.8 | 8.3 | ≤ 25 | 0.074-o.6 | 3-6 | 8500x3100x2100 | 17.6 |

MQG 1500x4500 | 28.8 | 10 | ≤ 25 | 0.074-04 | 4-8 | 9680x3200x2114 | 22.3 |

MQG 1500x5700 | 28.8 | 12 | ≤ 25 | 0.074-04 | 5-10 | 10440x3200x2114 | 26.7 |

MQG 1500x6400 | 28.8 | 13 | ≤ 25 | 0.074-04 | 8-12 | 11140x3200x2114 | 29.2 |

MQG 1830x3600 | 24.5 | 12 | ≤ 25 | 0.074-0.4 | 5-10 | 7880x4000x3370 | 31.4 |

MQG 1830x5400 | 24.5 | 15 | ≤ 25 | 0.074-04 | 5-20 | 9880x4685x3750 | 33.6 |

MQG 1830x6400 | 24.5 | 19 | ≤ 25 | 0.074-0.4 | 6-25 | 11710x4685x3750 | 36.5 |

MQG 1830x7000 | 24.5 | 20 | ≤ 25 | 0.074-0.4 | 8-30 | 12320x4685x3750 | 39.6 |

MQG 2100x3600 | 24.1 | 21 | ≤ 25 | 0.074-0.6 | 8-20 | 9016x4510x3720 | 43.2 |

MQG 2100x4500 | 24.57 | 26 | ≤ 25 | 0.074-0.6 | 8-35 | 10187x4685x3720 | 53.6 |