Mini DIY Desktop Extruder SJ20 Small Plastic Extrusion Line for Lab 3D Printing Filament Production Line

US $1,600.00-1,800.00 / set

1 set(s)Minimum order

plastic processed:

PE, PP, PVC, ABS, Polystyrene, PA, EVA, FRPP/PVC, HDPE, PPR, ABS/PP, HDPE/PP, PE/PP, Lldpe, LDPE

application:

Bar, Wire, PIPE, Granules, Sheet, Film, Profile, Plates, Filament, Pelletizing, Straw

Screw Design:

Single-screw

Screw Material:

38CrMoAlA

screw diameter (mm):

20

screw l/d ratio:

10:1

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PE, PP, PVC, ABS, Polystyrene, PA, EVA, FRPP/PVC, HDPE, PPR, ABS/PP, HDPE/PP, PE/PP, Lldpe, LDPE |

|---|---|

| application | Bar, Wire, PIPE, Granules, Sheet, Film, Profile, Plates, Filament, Pelletizing, Straw |

| Screw Design | Single-screw |

| Screw Material | 38CrMoAlA |

| screw diameter (mm) | 20 |

| screw l/d ratio | 10:1 |

| Screw Speed (rpm) | 70 rpm |

| place of origin | Jiangsu |

| brand name | Huiping |

| voltage | Customized |

| power (kw) | 0.12 |

| warranty | 1 Year |

| key selling points | Competitive Price |

| video outgoing-inspection | Provided |

| core components | motor |

| machinery test report | Provided |

| heating power | 400W |

| Gearbox | Planetary reducer |

| After-sales Service Provided | Field maintenance and repair service |

| After Warranty Service | Online support |

| Marketing Type | New Product 2020 |

| Condition | New |

| Showroom Location | None |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Warranty of core components | 1 Year |

| Weight | 68 KG |

Product Detail

Details Images

3D printing extrusion production line mainly includes:

1.Extruder

2.Mold

3.water tank

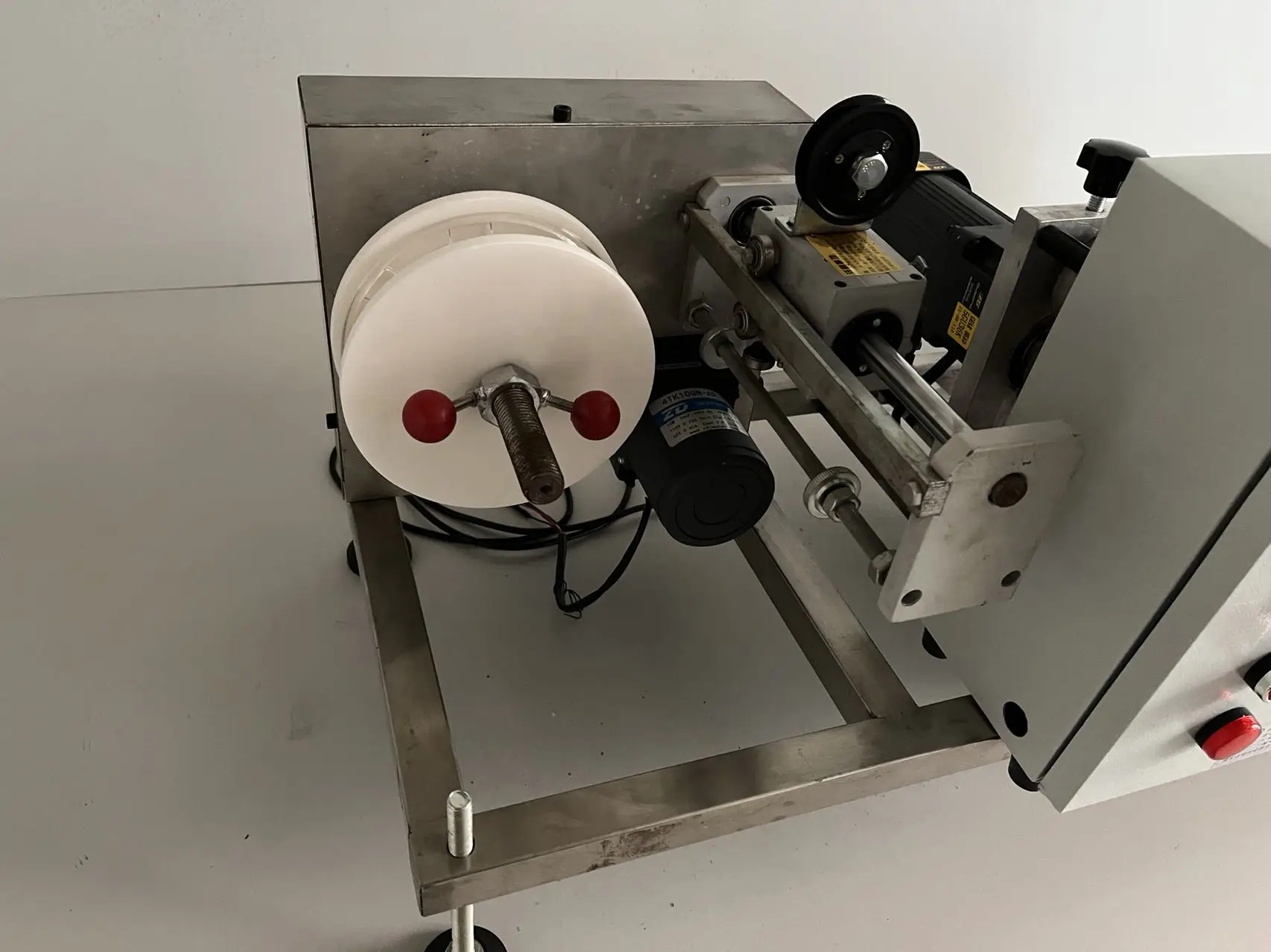

4.Haul off machine

5.Winder

Advantages:

1. Compared with other suppliers using the same model, the capacity is higher.

2. Ideal tolerance: +/-0.03mm, even + / - 0.01mm.

3. It can produce filaments with different diameters of 1.5mm-3.0mm.

4. Easy to operate: automatic control system.

5. Production of different raw materials: ABS PLA PA hips pet.

6. Low maintenance. After the machine was sold, we didn't receive any complaints.

7. It is very simple to install and operate the machine.

Size and weight:160X50X45cm 70kg

3D printing filament extruder | ||||||||

model | Capacity(kg/h) | Motor power(kw) | Diameter(mm) | |||||

SJ20 | 0.5 | 0.12 | 1.75 2.85 3.00 | |||||

SJ25 | 1-3 | 1.5 | 1.75 2.85 3.00 | |||||

SJ30 | 5-7 | 4.0 | 1.75 2.85 3.00 | |||||

SJ35 | 8-10 | 5.5 | 1.75 2.85 3.00 | |||||

SJ40 | 10-18 | 11 | 1.75 2.85 3.00 | |||||

Product Description

Extruder

1.Extruder screw diameter :20mm

2.L/D:10:1

3.using 120W motor

4.with 1 heating area

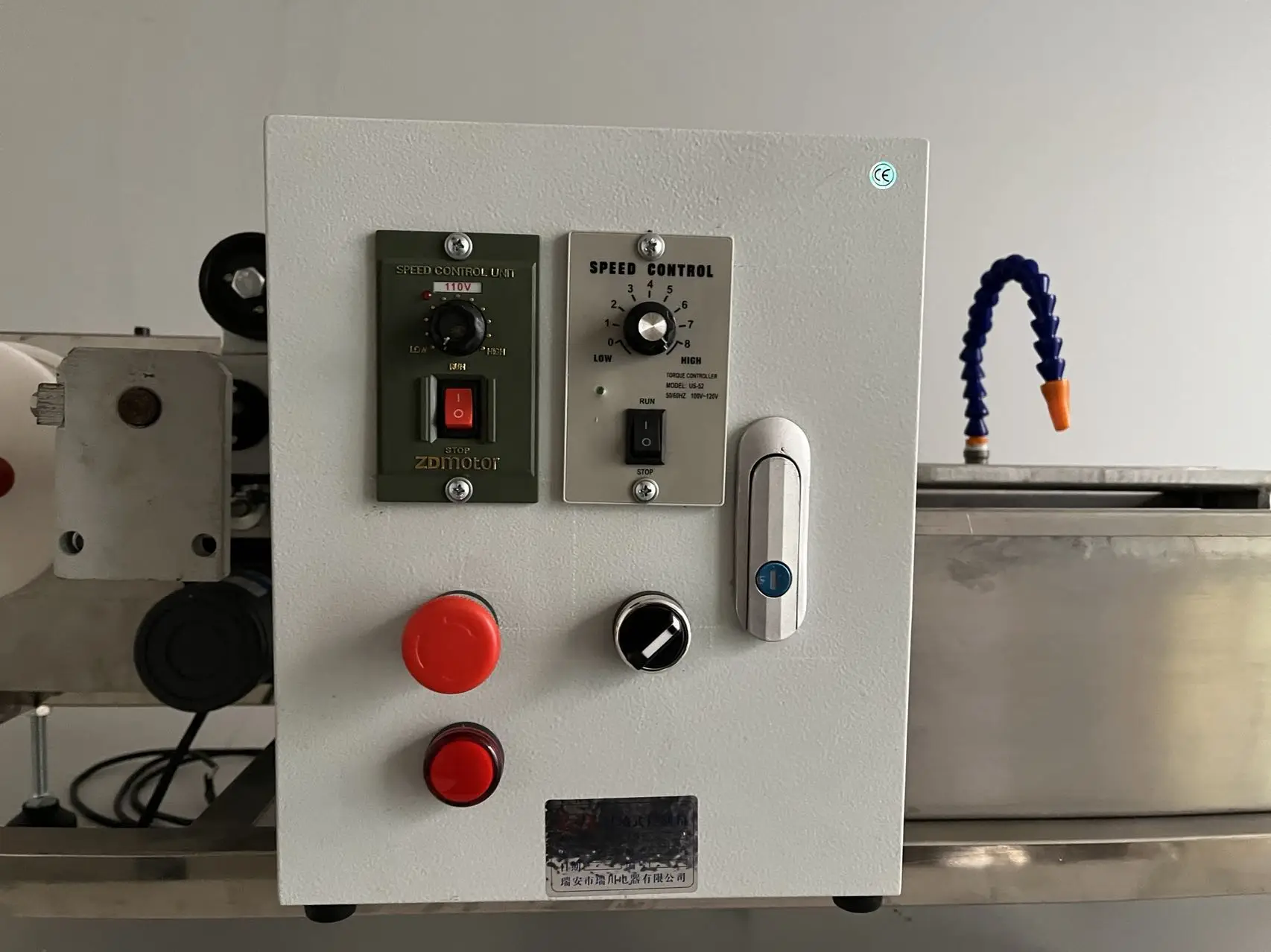

5.extrusion speed and heating temperature are controlled by Switch

Mold part

Molds are customized according to customer needs. Common ones are 1.75mm, 2.85mm and 3.00mm, and the error is controlled within 0.05mm.

Water tank

Cool the filament to further shape it.

Haul off machine

1.Power :120W

2.Traction speed: 0.1~ 0.5m / min

3.Traction speed regulation:Adjustable

Winding machine

With torque motor, automatic filament winding.

Company Profile

Zhangjiagang Huiping Machinery Co., Ltd.

The company is located in Zhangjiagang City, Jiangsu Province, which is an important place of mechanical production. It mainly produces various plastic pipe and profile extrusion production equipment, such as PVC plastic pipe profile production line, PE pipe production line, PP-R pipe production line, 3D consumables production line, high-speed mixer, centralized feeding system, etc. Can accept a variety of non-standard customized products. We have been engaged in the field of plastic extrusion for 12 years, accumulated rich experience and cooperated with many famous domestic universities, such as Peking University, Beijing University of technology, Suzhou University, etc. We will create a bright future for Huiping with the enterprise concept of the new century

We have been engaged in the field of plastic extrusion for 12 years and accumulated rich experience. We can accept all kinds of non-standard customized products. Looking forward to working with you.

Our Advantages

Packing & Delivery

After sales

1、after checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipments according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

2、after quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipments according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician.

FAQ

Q1. What material do you use?

A1.Such as PP、PPR、PVC、PE、ABS......

Q2. What diameter (mm) mould do you need( Mold shape)?

A2. Round hole or square hole,What diameter or size?.

Q3.Other requirements of your equipment, such as port, power supply, output?

Our company will carry out customized production according to your needs.