MITR Good Price Roller Jar Mill Single Station Model GMS5-1 Porcelain Laboratory Roller Ball Mill

US $646.00-857.00 / set

1 set(s)Minimum order

output (kg/h):

1 - 5 kg/h

feeding size (mm):

3 - 10 mm

output size (mesh):

300 - 1000 mesh

power (kw):

0.75

range of spindle speed(r.p.m):

5 - 270 r.p.m

material:

Other

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 1 - 5 kg/h |

|---|---|

| feeding size (mm) | 3 - 10 mm |

| output size (mesh) | 300 - 1000 mesh |

| power (kw) | 0.75 |

| range of spindle speed(r.p.m) | 5 - 270 r.p.m |

| material | Other |

| application | Food Processing, Chemicals Processing, Plastics Processing, Other |

| type | Ball Mill |

| Product Type | Other |

| place of origin | China (Mainland) |

| brand name | MITR |

| voltage | 220V |

| dimension(l*w*h) | 760*610*530MM |

| weight (kg) | 80 KG |

| warranty | 1 Year |

| key selling points | Long Service Life |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC |

| product name | Lab Roller Ball Mill |

| Feeding granularity | 1-5MM |

| Discharging granularity | 0.1-5UM |

| max speed of roller | 960rm |

| max speed of jar | 270rmin jar diameter:133mm |

| Transmission mode | belt drive |

| Volume and numbers of ball milling jar | 0.5-5L 1 jars |

| material capacity | 13 capacity of ball milling jar |

| Roller layers | 1*3 |

| Roller diameter * effective length | 50*220 |

| Condition | New |

| Applicable Industries | Manufacturing Plant, Farms, Construction works , Energy & Mining, Advertising Company |

| Showroom Location | United States |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

Product Detail

Product Paramenters

MITR Good Price Roller Jar Mill Single Station Model GMS5-1 Porcelain Laboratory Roller Ball Mill

Model | Jar Valume* Quantity | Roller Layers | Roller Piece | Roller Diameter* Length*Part | Adjust Distance With Handwheel | Frequency Conversion Speed Range | Voltage (V) | Power (kw) | Driving Mode |

GMS1-2 | (0.5-1L)*2 | 1 | 2 | Φ40*180 | 52~160 | 0~300 | 220V | 0.75 | Belt |

GMS3-2 | (0.5-3L)*2 | 1 | 2 | Φ50*220 | 52~210 | 0~300 | 220V | 0.75 | Belt |

JGMS3-2 | (0.5-3L)*2 | 1 | 2 | Φ58*200 | 76~225 | 0~300 | 220V | 0.75 | Belt |

GMS5-2 | (0.5-5L)*2 | 1 | 2 | Φ60*390 | 67~280 | 0~270 | 220V | 0.75 | Belt |

GMS10-2 | (0.5-10L)*2 | 1 | 2 | Φ70*390 | 67~230 | 0~220 | 220V | 1.5 | Synchronize Belt |

GMS20-2 | (0.5-20L)*2 | 1 | 2 | Φ80*470 | 30~340 | 0~220 | 380V | 2.2 | Synchronize Belt |

GMS30-2 | (0.5-30L)*2 | 1 | 2 | Φ80*(425*2) | 35~290 | 0~200 | 380V | 2.2 | Synchronize Belt |

GMS1-4 | (0.5-1L)*4 | 1 | 3 | Φ40*180 | 62~160 | 0~300 | 220V | 0.75 | Belt |

GMS3-4 | (0.5-3L)*4 | 1 | 3 | Φ50*230 | 76~230 | 0~270 | 220V | 0.75 | Belt |

GMS5-4 | (0.5-5L)*4 | 1 | 3 | Φ60*390 | 67~280 | 0~270 | 220V | 1.5 | Belt |

GMS10-4 | (0.5-10L)*4 | 1 | 3 | Φ70*(390*2) | 67~230 | 0~220 | 380V | 2.2 | Synchronize Belt |

GMS10-4B | (0.5-10L)*4 | 2 | 2 | Φ70*(390*2) | 67~230 | 0~220 | 380V | 2.2 | Synchronize Belt |

GMS20-4 | (0.5-20L)*4 | 2 | 3 | Φ80*(470*2) | 30~340 | 0~220 | 380V | 2.2 | Chain Wheel |

GMS30-4 | (1-30L)*4 | 1 | 3 | Φ80*(425*2) | 35~290 | 0~200 | 380V | 4 | Synchronize Belt |

GMS3-8 | (0.5-3L)*8 | 2 | 3 | Φ50*(230*2) | 76~230 | 0~280 | 380V | 1.1 | Belt |

GMS5-8 | (0.5-5L)*8 | 2 | 3 | Φ60*(310*2) | 67~280 | 0~270 | 380V | 2.2 | Chain Wheel |

GMS10-8 | (0.5-10L)*8 | 2 | 4 | Φ70*(410*2) | 67~302 | 0~220 | 380V | 3 | Chain Wheel |

GMS20-8 | (0.5-20L)*8 | 2 | 4 | Φ80*(470*2) | 30~340 | 0~220 | 380V | 3 | Chain Wheel |

Products Description

Features

1.Frequency conversion control speed, program control.

2.Adjusting the roller wheelbase by the hand wheel to prevent the jar movement.

3.The outer lining of the roller shaft with wear-resistant polyurethane to increase friction coefficient and prevent sliding jar

deformation.

4.Feeding granularity less than 3mm,soil <=10mm

2.Adjusting the roller wheelbase by the hand wheel to prevent the jar movement.

3.The outer lining of the roller shaft with wear-resistant polyurethane to increase friction coefficient and prevent sliding jar

deformation.

4.Feeding granularity less than 3mm,soil <=10mm

Company Profile

Changsha Mitr Insturment Equipment Co., Ltd. was established in 2007, headquartered in Changsha Hunan China. The company has been focusing on powder new material preparation for 16 years. Specialized in crusher, planetary ball mill, sand mill, grinding ball mill, glove box and related supporting equipment and provide related technical consulting solutions services.

We have exported more than 100 countries like USA, Australia, Mexico, Canada, Spain, Russia, Singapore, Thailand, Saudi Arabia, etc. Our main business is ultra-fine powder crushing / grinding / mixing six links to provide a one-stop solution from the experiment to the producion.

Why Choose Us

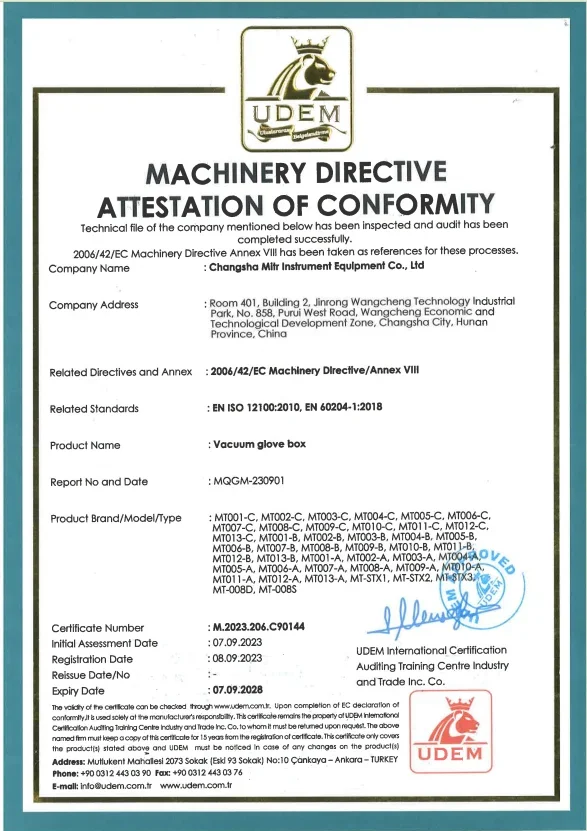

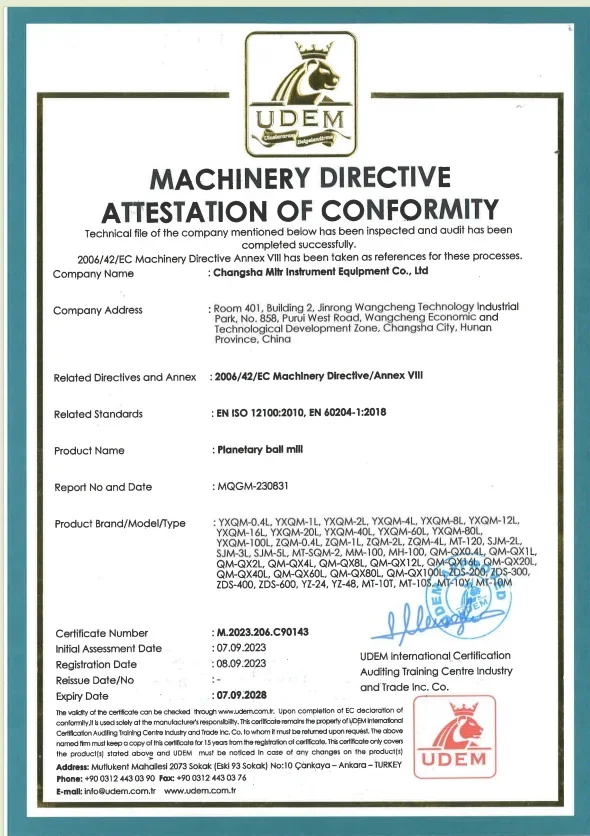

Certifications

FAQ

1.How to get technical support after purchasing?

Our factory provide online technical support in English , you can easy catch us online by Whatsapp and Email. If you need any remote assistances, we will have sales engineer to provide you with support.

2.What's the warranty for the items?

Usually, you will receive an order in perfect condition. If there are any quality issues, we will handle them immediately, and the equipment warranty period is 1 year.

3.Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.