MITR Stainless Steel Nylon PTFE Zirconium Agate Ball Mill Jars Dry Grinding Laboratory Small Roller Jar Mill Rolling Ball Mill

US $646.00-857.00 / set

1 set(s)Minimum order

output (kg/h):

1 - 5 kg/h

feeding size (mm):

3 - 10 mm

output size (mesh):

300 - 1000 mesh

power (kw):

0.75

range of spindle speed(r.p.m):

5 - 270 r.p.m

material:

Other

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| output (kg/h) | 1 - 5 kg/h |

|---|---|

| feeding size (mm) | 3 - 10 mm |

| output size (mesh) | 300 - 1000 mesh |

| power (kw) | 0.75 |

| range of spindle speed(r.p.m) | 5 - 270 r.p.m |

| material | Other |

| application | Food Processing, Chemicals Processing, Plastics Processing, Other |

| type | Ball Mill |

| Product Type | Other |

| place of origin | China (Mainland) |

| brand name | MITR |

| voltage | 220V |

| dimension(l*w*h) | 760*610*530MM |

| weight (kg) | 80 KG |

| warranty | 1 Year |

| key selling points | Long Service Life |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC |

| product name | Lab Roller Ball Mill |

| Feeding granularity | 1-5MM |

| Discharging granularity | 0.1-5UM |

| max speed of roller | 960rm |

| max speed of jar | 270rmin jar diameter:133mm |

| Transmission mode | belt drive |

| Volume and numbers of ball milling jar | 0.5-5L 1 jars |

| material capacity | 13 capacity of ball milling jar |

| Roller layers | 1*3 |

| Roller diameter * effective length | 50*220 |

| Condition | New |

| Applicable Industries | Manufacturing Plant, Farms, Construction works , Energy & Mining, Advertising Company |

| Showroom Location | United States |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

Product Detail

MITR Stainless Steel Nylon PTFE Zirconium Agate Ball Mill Jars Dry Grinding Laboratory Small Roller Jar Mill Rolling Ball Mill

Products Description

Main Application

Roller Jar Mill is widely used in electronic materials, ceramics, coatings, glass powder, fluorescent materials, non-metallic minerals, explosives, magnetic materials, equipment batteries, biological cultivation, food packaging, battery materials and other materials in the process of grinding and mixed.

The light jar mill is suitable for laboratory and small batch production.Because of it flexible and convenient operation, but also in some small business production.

The mixing roller jar mill is a an indispensable device for the slurry preparation process and in multiple fields. The main

features can be worked in a single station, double station, four station, eight station. You could choose it according to your

actual application requirement. This flexibility option is one of the advantage of this machine. It could be changeable for the working station. Such as: It could be used between 1-8 stations for the 8 stations machine, not restricted by odd or balance requirements.

The mixing roller jar mill is a an indispensable device for the slurry preparation process and in multiple fields. The main

features can be worked in a single station, double station, four station, eight station. You could choose it according to your

actual application requirement. This flexibility option is one of the advantage of this machine. It could be changeable for the working station. Such as: It could be used between 1-8 stations for the 8 stations machine, not restricted by odd or balance requirements.

Material Feed Size: <3mm (Suitable for brittle material, ultra-hardness materials are not suitable for this equipment )

Final Fineness : about 300mesh

Product Paramenters

Single Station Roller Jar Mill

This series is a single station with only a 5L ball mill jar, suitable for grinding or mixing of single experiments or small

samples

samples

Model | Jar Capacity | Roller Length | Power | Voltage | Layers/Station | Transmission Mode | Roller Speed |

GMS5-1 | 500ml-5L | Φ58*288 | 0.55(kw) | 220V 50Hz | 1/1 | Belt | 10-1000 |

Double Station Roller Jar Mill

This series is double stations with 1-2 ball grinding jars available between 3l / 5L/ 10L/ 20L/ 30L.Less sample for experimental or production used.

Model | GMS3-2 | GMS5-2 | GMS10-2 | GMS20-2 | GMS30-2 | ||||

Jar Capacity | 500ml-3L | 500ml-5L | 500ml-10L | 500ml-20L | 500ml-30L | ||||

Roller Diameter*Length(mm) | Φ58*(250*2) | Φ58*(290*2) | Φ68*(349*2) | Φ78*(349*2) | Φ78*(425*2) | ||||

Power | 0.75kw | 0.75kw | 1.1kw | 1.5kw | 2.2kw | ||||

Adjusted Space By Hand | 52-210 | 67-280 | 67-230 | 30-320 | 35-360 | ||||

Diameter of Jar | Φ50-Φ200 | Φ70-Φ260 | Φ60-Φ280 | Φ60-Φ320 | Φ60-Φ360 | ||||

Layers/Station | 1/2 Stations | 1/2 Stations | 1/2 Stations | 1/2 Stations | 1/2 Stations | ||||

Roller Speed | 5-1000 | 5-1000 | 5-1200 | 5-720 | 5-720 | ||||

Transmission Mode | Belt | Belt | Belt | Belt | Belt | ||||

Roller Nos | 2 | 2 | 3 | 3 | 3 | ||||

Four Stations Roller Jar Mill

This series has four stations with 1-4 pieces of ball mill jar, which can be selected between 1l / 3l / 5l / 10l / 20l / 20 l /

30l for small batch or multiple sample experiment or production.

30l for small batch or multiple sample experiment or production.

Model | GMS1-4 | GMS3-4 | GMS5-4 | GMS10-4 | GMS10-4B | GMS20-4 | GMS30-4 | ||||||

Jar Capacity | 500ml-1L | 500ml-3L | 500ml-5L | 500ml-10L | 500ml-10L | 500ml-20L | 500ml-30L | ||||||

Roller Diameter*Length(mm) | Φ38*(185*2) | Φ58*(250*2) | Φ58*(290*2) | Φ68*(349*2) | Φ68*(349*2) | Φ78*(424*2) | Φ78*(424*2) | ||||||

Power | 0.55kw | 0.55kw | 0.75kw | 1.5kw | 1.5kw | 3kw | 4kw | ||||||

Adjusted Space By Hand | 62-160 | 76-230 | 67-280 | 67-230 | 67-230 | 30-340 | 35-290 | ||||||

Diameter of Jar | Φ50-Φ160 | Φ70-Φ180 | Φ70-Φ260 | Φ60-Φ280 | Φ60-Φ280 | Φ60-Φ320 | Φ60-Φ360 | ||||||

Layers/Station | 1/4 Stations | 1/4 Stations | 1/4 Stations | 1/4 Stations | 1/4 Stations | 1/4 Stations | 1/4 Stations | ||||||

Roller Speed | 5-1000 | 5-1000 | 5-1000 | 5-1200 | 5-720 | 5-720 | 5-720 | ||||||

Transmission Mode | Belt | Belt | Belt | Belt | Belt | Belt | Belt | ||||||

Roller Nos | 3 | 3 | 3 | 3 | 4 | 4 | 4 | ||||||

Eight Stations Roller Jar Mill

This series is eight stations, can place 1-8 different jars, can be selected between 3l / 5l / 10l / 20l / 30l, suitable for

multi-sample experiment or production enterprises

multi-sample experiment or production enterprises

Model | GMS3-8 | GMS5-8 | GMS10-8 | GMS20-8 | |||

Jar Capacity | 500ml-3L | 500ml-5L | 500ml-10L | 500ml-20L | |||

Roller Diameter*Length(mm) | Φ58*(250*2) | Φ58*(290*2) | Φ68*(349*2) | Φ78*(424*2) | |||

Power | 1.1kw | 2.2kw | 3kw | 4kw | |||

Adjusted Space By Hand | 76-230 | 67-280 | 67-302 | 67-340 | |||

Diameter of Jar | Φ70-Φ200 | Φ70-Φ260 | Φ60-Φ280 | Φ60-Φ320 | |||

Layers/Station | 2/8 Stations | 2/8 Stations | 2/8 Stations | 2/8 Stations | |||

Voltage (V/hz) | 220v/50hz | 380v/50hz | 380v/50hz | 380v/50hz | |||

Roller Speed | 5-720 | 5-720 | 5-720 | 5-720 | |||

Transmission Mode | Belt | Belt | Belt | Belt | |||

Roller Nos | 6 | 6 | 6 | 8 | |||

Light Plastic Type

This series is four stations, can place 1-4 different jars, can be selected between 250ml / 500ml, suitable for laboratory

plasticizing bottles or PTFE bottles.

The other GMS series is suitable for kilogram samples, it is single active shaft. The feature is double active shaft. When fewer and lighter samples mixing and grinding in the jars,the friction is not enough for the heavy jars.

plasticizing bottles or PTFE bottles.

The other GMS series is suitable for kilogram samples, it is single active shaft. The feature is double active shaft. When fewer and lighter samples mixing and grinding in the jars,the friction is not enough for the heavy jars.

Model | Jar Size | Roller Length | Power | Voltage | Layers/Station | Transmission Mode |

QS-4 | 55mm-80mm | Φ38*422 | 0.25(kw) | 220V 50Hz | 1/4 Stations | Belt |

QS-16-A | 80mm-130mm | Φ58*670 | 1.1(kw) | 220V 50Hz | 2/16 Stations | Belt |

QS-16-B | 55mm-90mm | Φ58*670 | 1.1(kw) | 220V 50Hz | 2/16 Stations | Belt |

Cover Type

This series is with a cover, used for some special laboratory or production environment, can reduce noise, but also can prevent the laboratory jar/pot/tank, which is not lost powder in the equipment caused by flying accidents or convenient cleaning equipment.

Model | GMS5-1Z | GMS10-1Z | GMS5-2Z | GMS5-4Z | GMS10-4Z | GMS10-8Z |

Jar Capacity | 500ml-5L | 500ml-10L | 500ml-5L | 500ml-5L | 500ml-10L | 500ml-5L |

Roller Diameter*Length (mm) | Φ58*288 | Φ68*349 | Φ58*290 | Φ58*290 | Φ68*(349*2) | Φ68*(349*2) |

Power | 0.25kw | 1.1kw | 0.75kw | 0.75kw | 1.5kw | 3kw |

Adjusted Space By Hand | / | 67-230 | 67-280 | 67-280 | 67-230 | 67-302 |

Diameter of Jar | Φ58-Φ288 | Φ60-Φ280 | Φ70-Φ260 | Φ70-Φ260 | Φ60-Φ280 | Φ60-Φ280 |

Layers/Station | 1/1 Stations | 1/1 Stations | 1/2 Stations | 1/4 Stations | 1/4 Stations | 2/8 Stations |

Voltage | 220v/50hz | 220v/50hz | 220v/50hz | 220v/50hz | 380v/50hz | 380v/50hz |

Roller Speed | 5-900 | 5-1200 | 5-1000 | 5-1000 | 5-1200 | 5-720 |

Transmission Mode | Belt | Belt | Belt | Belt | Belt | Belt |

Roller Nos | 2 | 2 | 2 | 3 | 3 | 6 |

Jar Types Selection Help

Nylon ball mill jar features: One kind of higher hardness in polymer material. The wear resistance is also high. It is one of them that should be more extensive at present.

In the use of GMS series roller jar ball mill, the jar selection is more important. The main laboratory selection will be biased

to high purity jar. Such as agate, zirconium, polyurethane, nylon jar. In the production line, the selection will be polyurethane

and nylon. Due to it is used the large capacity jar in production line and it is hard to move it by some one loading. Then both nylon and polyurethane are highly wear-resistant and polymer materials. There are many choices for the later process treatment. Polyurethane and nylon process is also mature, the cost is relatively low, so by more customers choose.

Stainless steel ball mill jar features:304 Stainless steel corrosion resistant (not strong corrosion).Such ball mill jars may be selected for some special samples which have corrosion resistance requirements

Alumina ball mill jar features:The main content of alumina jar is Al2O3. It is made by sintering.Hardness, wear resistance are relatively level. The grinding effect is relatively good.

Polyurethane ball mill jar features: High purity, strong wear resistance, high surface finish, is one of the better mixed jar selection.

PTFE ball mill jar features: Strong corrosion resistance is the prominent characteristics of this material.

Zirconium / agate / carbide jars should be used with shared sets.

Alumina ball mill jar features:The main content of alumina jar is Al2O3. It is made by sintering.Hardness, wear resistance are relatively level. The grinding effect is relatively good.

Polyurethane ball mill jar features: High purity, strong wear resistance, high surface finish, is one of the better mixed jar selection.

PTFE ball mill jar features: Strong corrosion resistance is the prominent characteristics of this material.

Zirconium / agate / carbide jars should be used with shared sets.

In the use of GMS series roller jar ball mill, the jar selection is more important. The main laboratory selection will be biased

to high purity jar. Such as agate, zirconium, polyurethane, nylon jar. In the production line, the selection will be polyurethane

and nylon. Due to it is used the large capacity jar in production line and it is hard to move it by some one loading. Then both nylon and polyurethane are highly wear-resistant and polymer materials. There are many choices for the later process treatment. Polyurethane and nylon process is also mature, the cost is relatively low, so by more customers choose.

Grinding balls selection: agate ball, zirconium ball, stainless steel ball, polyurethane ball, alumina ball, tungsten carbide

ball, PTFE ball, silicon carbide ball, silicon nitride ball, etc

ball, PTFE ball, silicon carbide ball, silicon nitride ball, etc

Specifications | 500ml | 1L | 2L | 3L | 5L | 10L | 15L | 20L | 25L |

Stainless Steel Ball Mill Jar | * | * | * | * | * | * | * | * | * |

PTFE Ball Mill Jar | * | * | * | * | * | * | * | ||

Polyurethane Ball Mill Jar | * | * | * | * | * | * | * | ||

Nylon Ball Mill Jar | * | * | * | * | * | * | * | * | * |

Alumina Ball Mill Jar | * | * | * | * | * |

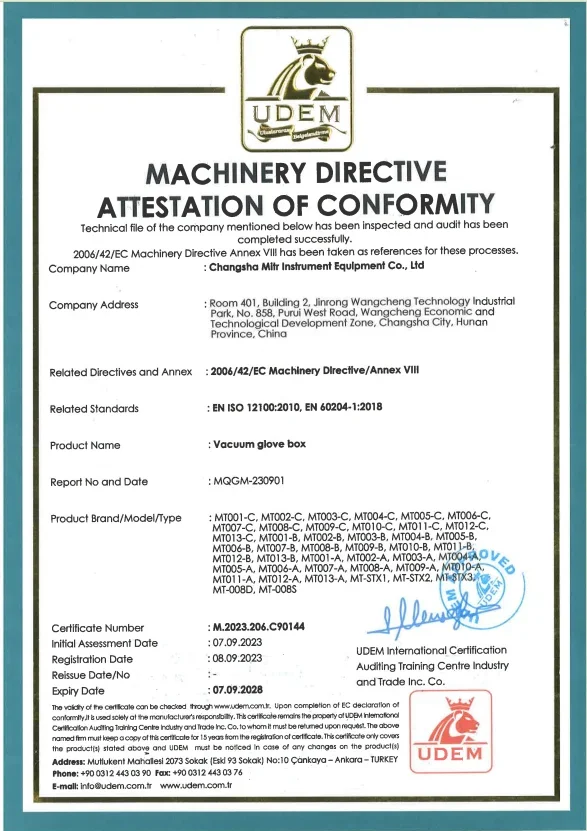

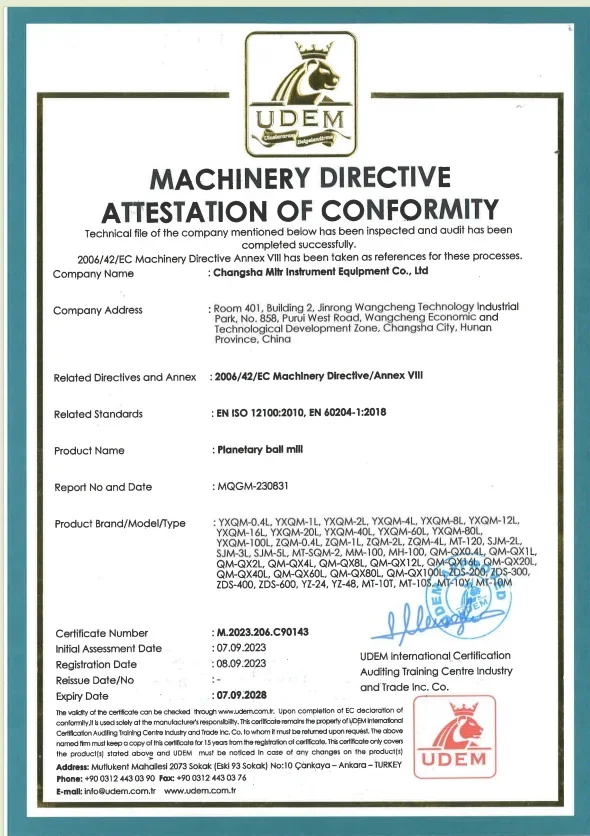

Company Profile

Changsha Mitr Insturment Equipment Co., Ltd. was established in 2007, headquartered in Changsha Hunan China. The company has been focusing on powder new material preparation for 16 years. Specialized in crusher, planetary ball mill, sand mill, grinding ball mill, glove box and related supporting equipment and provide related technical consulting solutions services.

We have exported more than 100 countries like USA, Australia, Mexico, Canada, Spain, Russia, Singapore, Thailand, Saudi Arabia, etc. Our main business is ultra-fine powder crushing / grinding / mixing six links to provide a one-stop solution from the experiment to the producion.

Why Choose Us

FAQ

1.How to get technical support after purchasing?

Our factory provide online technical support in English , you can easy catch us online by Whatsapp and Email. If you need any remote assistances, we will have sales engineer to provide you with support.

2.What's the warranty for the items?

Usually, you will receive an order in perfect condition. If there are any quality issues, we will handle them immediately, and the equipment warranty period is 1 year.

3.Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.

Our factory provide online technical support in English , you can easy catch us online by Whatsapp and Email. If you need any remote assistances, we will have sales engineer to provide you with support.

2.What's the warranty for the items?

Usually, you will receive an order in perfect condition. If there are any quality issues, we will handle them immediately, and the equipment warranty period is 1 year.

3.Can you provide testing service of grinding experiment before we place an order?

Yes. sample grinding experiment is available for any customer who is willing to send materials to us, and grinding experiment of sample is always free of charge.