Naipu 300FF - LR Coal Ash Tailing Circulation Slurry Pump Manufacturers

Other recommendations for your business

Contact us

Quik Detail

| warranty | 1 year |

|---|---|

| customized support | OEM, ODM, OBM |

| brand name | NP |

| model number | 300FF-LR |

| place of origin | Hebei, China |

| application | Industrial Utilities, Machining, Marine, Metal and Equipment Manufacturers, Mining industry, Pharmaceutical industry, Wastewater Transport and Flood Control, wastewater treatment |

| horsepower | 747 HP |

| power source | Electric |

| pressure | Low pressure |

| structure | Single-stage Pump |

| outlet size | 300 mm |

| voltage | 380V, 415V, 440V, 460V... |

| power | 560 kw |

| Usage | Water |

| Theory | Centrifugal Pump |

| OEM | Accepted |

| Material | natural rubber, NR55,... |

| Flow rate | 432-1900 m3/h |

| Pump head | 7-41 m |

| Impeller | Closed |

| Warranty | 1 Year (except Wearing Parts) |

| Type | Horizontal Slurry Pump |

| Application | Coal Washing, Chemical Medium Processing, Effluent Handling |

Product Detail

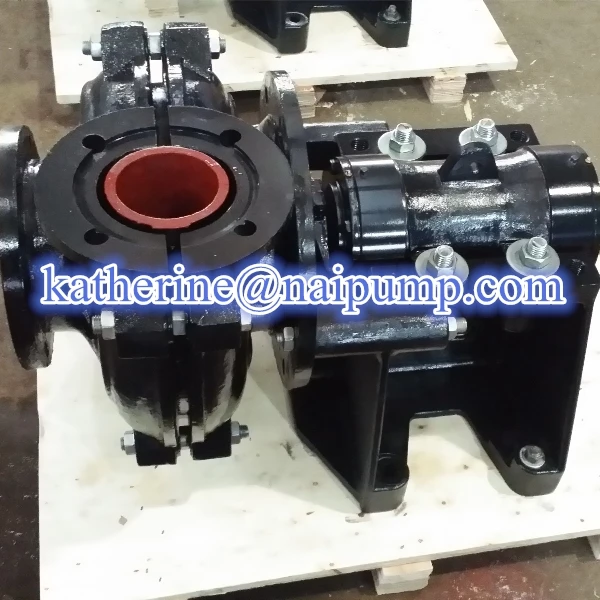

Naipu 300FF - LR Coal Ash Tailing Circulation Slurry Pump Manufacturers

L(R) Horizontal Slurry Pump

Rubber Liner Material

R08 is a black natural rubber, of low to medium hardness. R08 is used for impellers where superior erosive resistance is required in fine particle slurries.

R26 is a black, soft natural rubber. R26 is used for lines where superior erosion resistance to all other materials in fine particle slurry applications.

R33 is a premium grade black natural rubber of low hardness and is used for cyclone and pump liners and impellers where its superior physical properties give increased cut resistance to hard, sharp slurries.

NR55 is premium grade black natural rubber, it is suitable for severe erosive fine particle slurries.

Slurry Pump Replacement Parts 300S-L: RSL30147NR55 , RSL30018NR55 , RSL30036NR55, RSL30083NR55

Slurry Pump Replacement Parts 350S-L: SL35147NR55, SL35083NR55, SL35041NR55, SL35018NR55, SL35043NR55

Slurry Pump Replacement Parts 400ST-L: STL40147NR55, TL40018NR55, TL40043NR55, TL40083NR55, TL40041NR55

Slurry Pump Replacement Parts 450ST-L: STL45147NR55, TL45018NR55, TL45043NR55 , TL45083 NR55, TL45041NR55

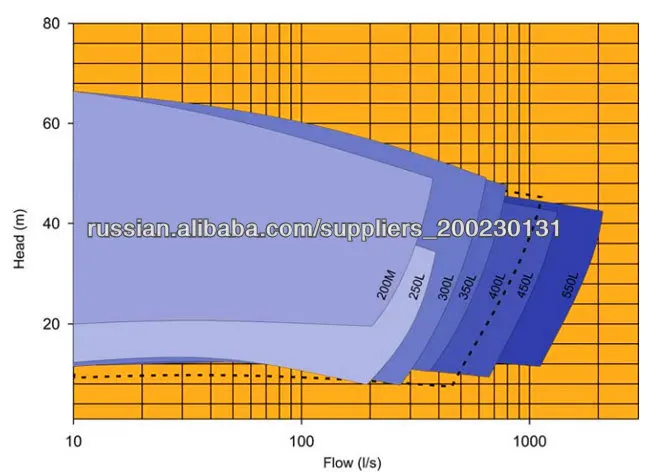

L(R) slurry pump selection chart

( Note: Approximate performance for clear water,to be used for primary selection only.)

L Slurry Pump performance parameters

|

Type |

Max. Power Kw |

Clear Water Performance |

Impeller |

Application

|

|||||

|

Capacity m³/hr |

Head/m |

Speed/rpm |

Efficiency % |

NPSH m |

Nos of Vane |

Diameter mm |

|||

|

20A-L |

7.5 |

2.34-10.8 |

6-37 |

1400-3000 |

30 |

3.5-8 |

4 |

152.4 |

-Ball mill discharge |

|

50B-L |

15 |

16.2-76 |

9-44 |

1400-2800 |

55 |

3.5-8 |

5 |

190 |

-Coarse tailings |

|

75C-L |

30 |

18-151 |

4-45 |

900-2400 |

57 |

3-6 |

4 |

229 |

-Rod mill discharge |

|

100D-L |

60 |

50-252 |

7-46 |

800-1800 |

60 |

2-3.5 |

4 |

305 |

-Coal washing |

|

150E-L |

120 |

115-486 |

12-51.5 |

800-1500 |

65 |

2-6 |

4 |

381 |

-Wet crushers |

|

200E-L |

120 |

234-910 |

9.5-40 |

600-1100 |

64 |

3-6 |

4 |

457 |

-Phosphate matrix |

|

250F-L |

120 |

396-1425 |

8-30 |

500-800 |

77 |

2-10 |

5 |

550 |

-Minerals concentrate |

|

300S-L |

560 |

468-2538 |

8-60 |

400-950 |

79 |

2-10 |

5 |

653 |

-Lime grinding |

|

350S-L |

560 |

650-2800 |

10-59 |

400-840 |

81 |

3-10 |

5 |

736 |

-FGD waste water |

|

400ST-L |

560 |

720-3312 |

7-51 |

300-700 |

80 |

2-10 |

5 |

825 |

-Flotation |

|

450ST-L |

560 |

1008-4356 |

9-48 |

300-600 |

80 |

2-9 |

5 |

933 |

-Process chemical |

|

550TU-L |

1200 |

1980-7900 |

10-50 |

250-475 |

86 |

4-10 |

5 |

1213 |

-Pulp and paper |

|

20A-LR |

7.5 |

2.16-9 |

7-32 |

1600-3000 |

30 |

|

3 |

152.4 |

-Ni acid slurry |

|

50B-LR |

15 |

12.6-60 |

6-38 |

1200-2600 |

48 |

|

3 |

190 |

-Coarse sand |

|

75C-LR |

30 |

22-144 |

9-43 |

1000-2200 |

60 |

3-5 |

4 |

229 |

-Heavy media |

|

100D-LR |

60 |

61-252 |

17-70 |

800-1600 |

65 |

2-5 |

6 |

305 |

-Bottom/fly ash |

|

150E-LR |

120 |

137-486 |

12-51.5 |

800-1300 |

65 |

2.5-5.5 |

5 |

381 |

-Oil sands |

|

200E-LR |

120 |

216-990 |

9.5-40 |

500-1100 |

74 |

|

5 |

457 |

-Mineral sands |

|

250F-LR |

260 |

324-1314 |

8-30 |

500-800 |

70 |

5--10 |

5 |

550 |

-Fine tailings |

|

300S-LR |

560 |

432-1900 |

7-41 |

400-800 |

81 |

3-8 |

5 |

653 |

-Phosphoric acid |

|

350S-LR |

560 |

720-2844 |

10-41 |

400-700 |

86 |

3-7 |

5 |

736 |

-Coal |

|

400ST-LR |

560 |

756-3312 |

7-37.5 |

300-600 |

85 |

2-8 |

5 |

825 |

|

|

450ST-LR |

560 |

1080-4356 |

9-40 |

300-550 |

87 |

3-10 |

5 |

933 |

|

|

650U-LR |

2000 |

2520-9108 |

10-39 |

200-350 |

86 |

2-8 |

5 |

1370 |

|

|

750UV-LR |

2000 |

3240-13860 |

8-41 |

150-300 |

86 |

2-8 |

5 |

1643 |

|

1. Slurry pump construction drawing

Centrifugal Slurry Pump Main part number at the drawing

| 032: Frame Plate 060: Intake Joint 132: Discharge Joint 083: Throatbush 110: Volute Liner 147: Impeller |

122: Stuffing Box Seal 036: Frame Plate Liner 013: Cover Plate 018: Cover Plate Liner 124: Volute Liner Seal 041: Frame Plate Liner Insert |

Mining Slurry Pump Materials of construction

| LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS | |

| Standard | Chrome Alloy Natural Rubber |

Chrome Alloy Natural Rubber |

SG Iron | SG Iron | Chrome Alloy or SG Iron |

Chrome Alloy or SG Iron |

SG Iron | Rubber and Nitrile |

| Options | Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Viton Nitrile EPDM Hypalon |

Ferralium Hastelloy C 316 SS W151 Polyurethane Neoprene Butyl Nitrile Hypalon |

SG Iron Various grades |

MS Fabricated Cast Iron |

NI Resist Ferralium Hastelloy C Polyurethane 316 SS W151 |

NI Resist Ferralium Hastelloy C 316 SS Rubber W151 Polyurethane Neoprene Butyl Nitrile |

EN56C Ferralium Hastelloy C Titanium 316 SS 304 SS |

Ceramic Stellite Chrome Oxide Nordel Neoprene Viton |

Q1. How slurry pump works?

A: AH(R) slurry pumps are those of cantilever, horizontal and centrifugal ones, which are widely used to transport corrosive/ abrasive and high concentration slurry in many industries.

Q2. How to gurantee the quality?

A: All our pump and spare parts pass ISO 9001:2008 and CE certificate. Warranty time is 12 month except wet end parts.

Q3. What information should be known if I want to get a quotation?

A: Pump working conditions, Usage , Pump Capacity, pump Head , Slurry SG, The More the Better. Please offer me the type of the used pump that working now.

Q4. Manaufacturer or trader?

A: Manufacturer of couse. Our Factory located in Shijiazhuang , Hebei , China . Welcome to visit.

Q5. Your company product range?

A: Centrifugal pump, Slurry pump, Sand pump, Gravel pump, Dredging pump, Clean water pump, Sewage pump, Chemical pump, Single stage pump, Double suction pump, Industry pump, Paper pulp pump, Mud pump, Sludge pump, etc

Q6. Delivery time:

A: For the Common Slurry pump and spare parts , the delivery time within 7-15 days. Special material and OEM production is longer.

CE, SGS, ISO9001 Certification

Katherine Hou

Shijiazhuang Naipu Pump Co., Ltd is a professional manufacturing enterprise of slurry pumps and spare parts. Which own Mould Workshop, Casting Workshp, Machining Workshop and Assembly Workshop.