NEW Gold Stamp Mill for Gold Selection /gold Ore Grinding Mill/wet Gold Pan Mill Used in South African

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, Gearbox, motor, Gear |

| Type | wet pan mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 15-160 |

| Place of Origin | Henan, China |

| Brand Name | UNIQUE |

| Dimension(L*W*H) | Customized |

| Weight | 91 KG |

| Warranty | 1 Year |

| After-sales Service Provided | Engineers available to service machinery overseas |

| After sale service | Spare parts supply |

| Product Name | Continuous Cement Ball Mill |

| Application | gold ore |

| Warranty period | More than 12 months |

| Feeding size | ≤25mm |

| Certification | CE ISO |

| Applicable Industries | Construction works , Manufacturing Plant, Energy & Mining |

| Showroom Location | Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Mexico, Russia, Thailand, Morocco, Argentina, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Malaysia, Australia |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Condition | New |

Product Detail

The Introduction of wet pan mill

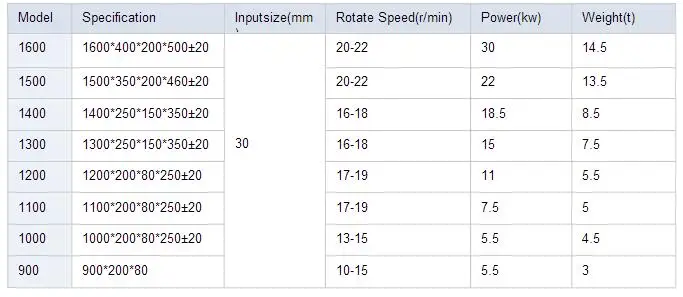

A wet pan mill is the best equipment to replace a ball mill. because it has small investment, high output, low production cost, good efficiency, and easy installation. And the machine is the ideal beneficiation equipment for small and medium-sized enterprises. A wet pan mill is mainly used to process gold, silver, lead, zinc, iron, molybdenum, copper, and antimony. The wet pan mill is named by the diameter of the roller. Φ1300, Φ 1350, Φ 1400, Φ 1500, Φ 1600 are suitable for the selection of iron ore, molybdenum ore, lead ore, zinc ore, antimony ore, and so on. Φ 850, Φ 900, Φ 1000, Φ 1100, Φ 1200 is suitable for selection of gold ore. Above all, the 1200a type is the most popular and widely used.

Working Principle of wet pan mill

The Wet pan mill repeatedly squeezes and mill gold ore through the weight of the wheels until the gold ore has been crushed completely. And then add 1 kg mercury into the water. Meantime, every 5-10 minutes, add gold ore to the machine. After 24 hours, recycle mercury. Then pack mercury with a big density of cloth. Twist the cloth and let the mercury come out. The gold will be left in the cloth.

Shipping:we deliver the cargo to China's main sea ports,such as Qingdao,Tianjin,Shanghai etc.And then the container will be transported to your country by sea.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply