OEM CNC Lathe Turning Aluminum 6061 Tubes Anodized Aluminum Tube Machining Stainless Steel Tube Machining

1 piece(s)Minimum order

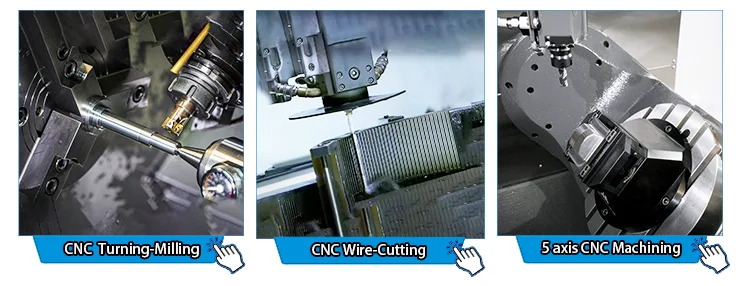

CNC Machining or Not:

Cnc Machining

Type:

DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities:

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not:

Micro Machining

Place of Origin:

Guangdong, China

Model Number:

OEM

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| CNC Machining or Not | Cnc Machining |

|---|---|

| Type | DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Micro Machining or Not | Micro Machining |

| Place of Origin | Guangdong, China |

| Model Number | OEM |

| Brand Name | OEM |

| Keyword | CNC Aluminum Metal Machining Turning Milling Motorcycle Parts |

| Our Service | CNC Machining, Sheet Metal, Laser Cutting, Die Casting, 3D Printing |

| Material | Aluminum ,Bras ,Stainless Steel,POM,Carbon Steel |

| Surface treatment | Sandblasting,Anodized, Powder Coating,Polishing,Plating |

| Tolerance | 0.01- +/-0.005mm |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Color | Customized Color |

| Certification | TUV |

| Packing | Poly Bag + Inner Box + Carton |

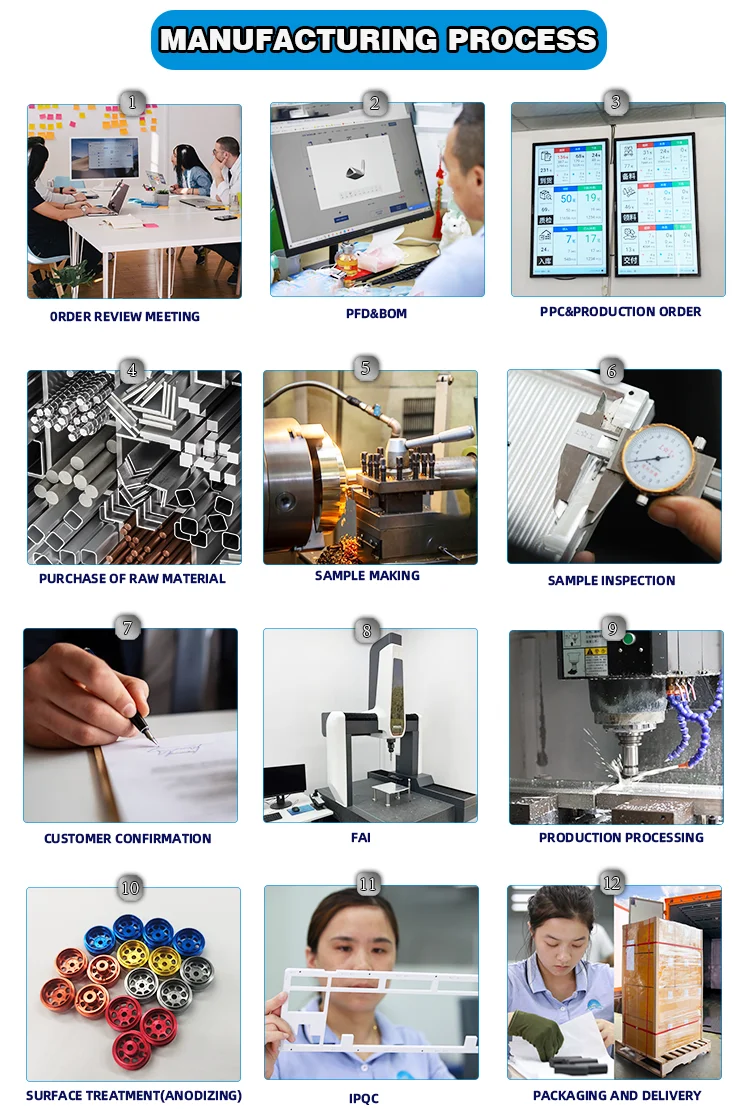

| Delivery Time | Sample:3-7days |

Product Detail

MOQ: | 1PCS. |

Service: | 24 Hour Service,30 Minute Quick Quote. |

Samples: | 1-3 days,Delivery:7-14 days. |

Our Mission: | Quality Control Team,Imported inspection equipment ,Lifetime after sales service. |

Certifications: | ISO9001,IS014001,1s004500,IATF2016,QC080000,CE,ROHS. |

Material: | Sus303,sus304,Ss316,SS316L,420,430174/PH1214L/1215/4140/SCM440/40CrMo, etc. |

Tolerance: | +/-0.01-0.005mm |

Special Areas: | +/-0.002mm |

Surface Roughness: | Ra 0.1~3.2 |

Supply Ability: | 500000Piece/Month |

Surface Treatments: | electroplating, galvanizing, spraying, oxidation, polishing, spray grinding, passivationheat treatment, pickling,shot peening,etc. |

On-demand CNC machining service for rapid prototyping and production parts, through a network of specialized, experienced, and thoroughly vetted local and global CNC machine shops.

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into

final parts.

Source high-performing parts in more than 50 different metals

and plastics via our network of advanced CNC turning experts. Tight tolerances available, down to ±.0008.

Capable of performing both turning and milling operations on the same machine. CNC systems provide high accuracy and repeatability. Reduces time spent on workpiece setup and adjustment. Suitable for machining complex shapes and multi-faceted parts.

As a precision machining process, it can produce complex shapes and tight tolerances with minimal deformation, allowing for the machining of intricate geometries and detailed designs.

Our CNC milling process produces custom prototypes and end-use production parts in as fast as 1 day. We use 3-axis milling and 5-axis indexed milling processes to manufacture parts from more than 30 engineering-grade plastics and metals.

(1) Physical surface treatment: sandblasting, wire drawing, shot blasting, polishing, rolling, brushing, spraying, painting,

powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

powder spraying, silk screen printing, pad printing, water transfer printing, electrophoresis, etc.

(2) Chemical surface treatment: bluish blackening, phosphating, pickling, electroless plating, TD treatment, QPQ treatment,

carburizing, nitriding, chemical oxidation, passivation, etc.

carburizing, nitriding, chemical oxidation, passivation, etc.

(3) Electrochemical surface treatment: anodic oxidation, hard anodic oxidation, electrolytic polishing, electroplating, etc.

(4) Modern surface treatment: chemical vapor deposition (CVD), physical vapor deposition (PVD), ion implantation, ion plating,laser surface treatment, etc.

Q1:How to enjoy the OEM services? |

A1: Simply provide us with your design drawings or original samples. We will offer technical suggestions and a quotation. Once you approve, we proceed with production. |

Q2: Will my design drawings be kept confidential? |

A2: Absolutely. We do not share your designs with any third party without your explicit consent. We can sign a Non-Disclosure Agreement (NDA) before you send us the drawings to ensure your designs are fully protected. |

Q3: How soon can I receive samples? |

A3: The sample lead time depends on your specific project, but it typically takes 7 to 20 days. |

Q4: Can I track my product's progress without visiting your company? |

A4: Absolutely! We will provide you with a detailed production schedule and send weekly updates, including digital photos andvideos, to show the progress of your order. |

Q5: How do you prevent quality issues in large orders? |

A5: We focus on preventative measures and inspections throughout the production process. Key processes are set as critical control points, and our team follows up with thorough inspections to maintain quality throughout the entire production cycle. |

Q6:How to handle if there are abnormalities upon product arrival? |

A6: Our company will review the process within 1 hour to identify the issue and provide feedback to you. A redo will be arranged within 2 hours, and a refund will be issued. |