OEM Manufacturer Inverter Rigid Printed Circuit Board PCB Manufacturing and Assembly Customized Electronic Board Amplifier PCBA

US $1.00-5.00 / piece

3 piece(s)Minimum order

Model Number:

Amplifier PCBA 11

Type:

consumer electronics pcba

Place of Origin:

Guangdong, China

Brand Name:

PS Electronics

Copper Thickness:

0.5-20oz (max 33oz)

Turnkey Service:

PCB + Components Sourcing + Stencil + Assembly + Package

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Model Number | Amplifier PCBA 11 |

|---|---|

| Type | consumer electronics pcba |

| Place of Origin | Guangdong, China |

| Brand Name | PS Electronics |

| Copper Thickness | 0.5-20oz (max 33oz) |

| Turnkey Service | PCB + Components Sourcing + Stencil + Assembly + Package |

| Assembly Details | 6 SMT + 4 DIP (Dust and anti-static lines) |

| Assembly Abilities | SMT 4.5 million points per day, DIP 10 thousands pieces per day |

| MOQ | 3 PCS |

| Quality Standards | IPC-A-600H, IPC-A-610F, J-STD-001F |

| PCB Panel Size | Min: 0.25x0.25 inches (6x6mm) Max: 20x20 inches (500x500mm) |

| Assemble Type | SMT, THT & Hybrid, single or double side placement |

| PCB Solder Type | Water soluble solder paste, RoHS lead-free |

| Layer Count | 1-40 |

| Packaging | Anti-Static Bags/Customized Packaging |

Product Detail

PCB Parameter

Item | PCB Parameters |

Material | FR4 (140Tg, 170Tg, 180Tg), FR-406, FR-408, 370HR, IT180A, Metal Core, Polyimide, Rogers 4350B/3003/4003C/5880, Taconic, Teflon, etc |

Material Brands | KB, ITEQ, SY, ISOLA, Rogers (Arlon), Ventec, Laird, Nelco, Bergquist, DENKA, Panasonic, Taconic, or other laminate on customer's request |

Layer Count | 1-40 |

Flammaility | UL 94V-0 |

Thermal Conductivity | 0.3W-300W/mk |

Quality Standards | IPC Classes 2/3 |

HDI Build-up | Any Layer, up to 3+N+3 |

Board Thickness | 0.2~7mm |

Min Thickness | 2-layer: 0.2mm 4-layer: 0.4mm 6-layer: 0.6mm 8-layer: 0.8mm 10-layer: 1mm More than 10 layers: 0.5*Layer Count*0.2mm |

Copper Thickness | 0.5-20oz |

Inks | Super White Inks/Solar/Carbon Inks |

Solder Mask Thickness | 0.2mil-1.6mil |

Surface Finishes | Bare Copper, Hasl lead-free, ENIG, ENEPIG, Gold Fingers, OSP, IAg, ISn, etc |

Plating Thickness | HASL: Copper Thickness: 20-35um Tin: 5-20 um Immersion Gold: Nickel: 100u"-200u" Gold: 2u" -4u" Hard Plated Gold: Nickel: 100u"-200u" Gold: 4u"-8u" Golden Finger: Nickel: 100u"-200u" Gold: 5u"-15u" Immersion Silver: 6u"-12u" OSP: Film 8u"-20u" |

Min Hole Size | 0.15mm |

Min Trace Width/Spacing | 2mil/2mil |

Via Plugging | 0.2~0.8mm |

Line Width/Space Tolerance | ±10% |

Board Thickness Tolerance | ±5% |

Hole Diameter Tolerance | ±0.05mm |

Hole Location Tolerance | ±2mil |

Layer to Layer Registration | 2mil |

S/M Registration | 1mil |

Aspect Ratio | 10:01 |

Blind Vias Aspect Ratio | 1:01 |

Outline Tolerance | ±0.1mm |

V- CUT Tolerance | ±10mi |

Bevel Edge | ± 5mil |

Warp and Twist | ≤0.50% (max cap) |

Quality Test | AOI, 100% E-test |

Value-Added Services | DFM Check, Expedited Production |

Featured Processes | Bonding, Impedance Control, Via in Pad, Press Fit Hole, Countersink/Counterbore Hole, Castellated Vias, Edge Plating, Peelable Solder Mask, Resin Plugged, Plating Flat |

Data Formats | Gerber, DXF, PCBdoc, ODB++, HPGL, BRD, etc |

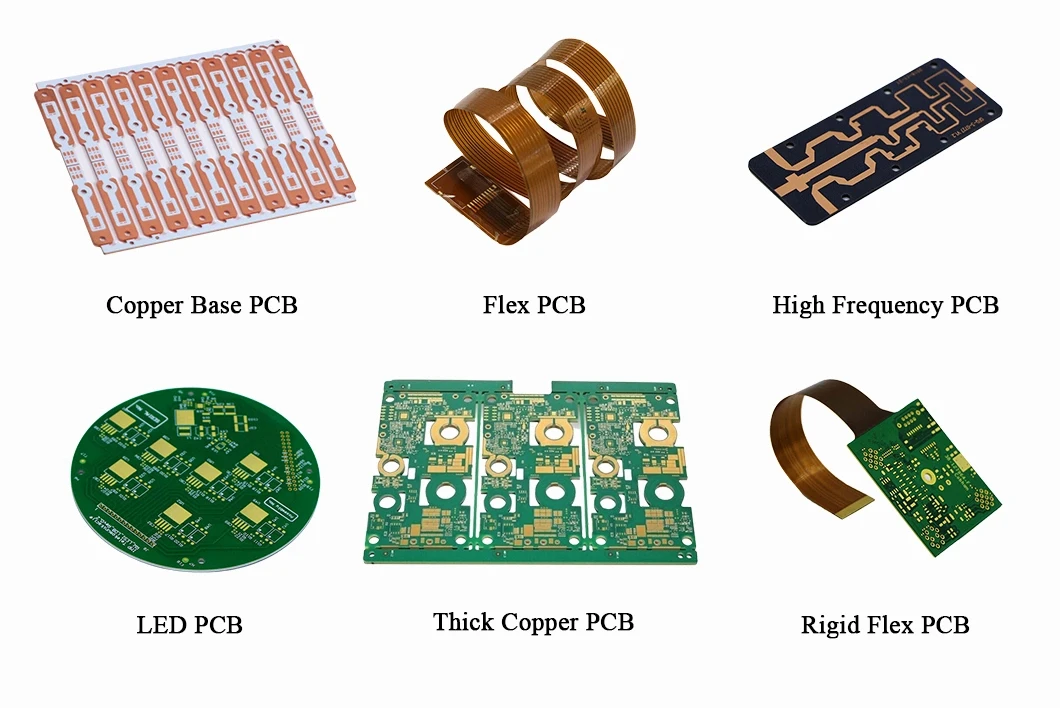

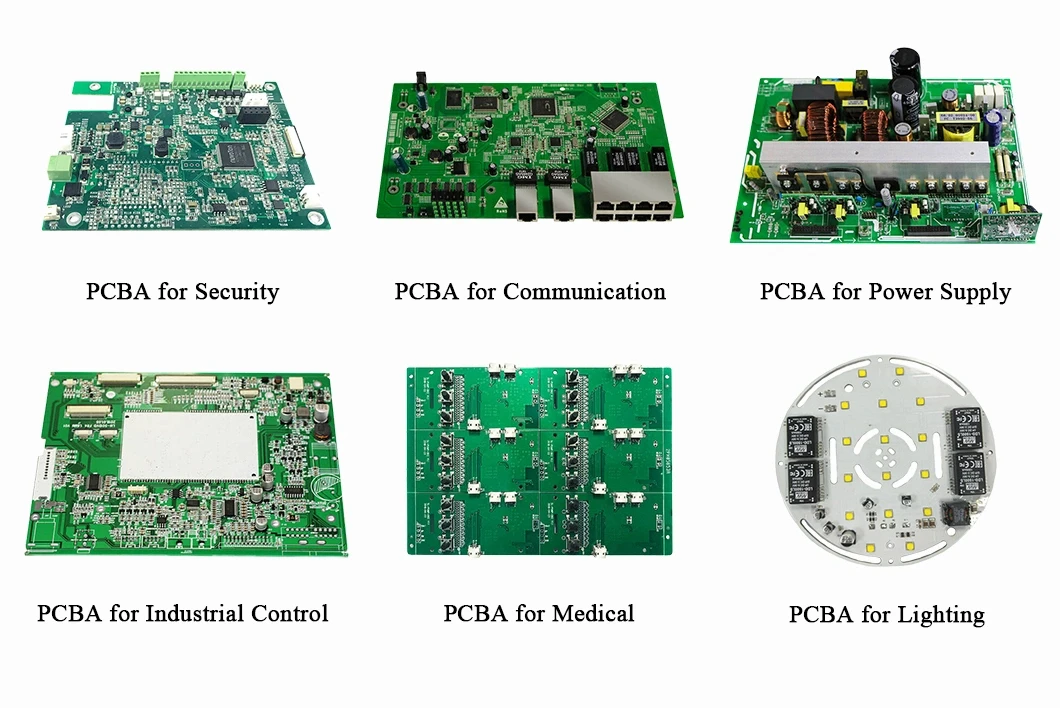

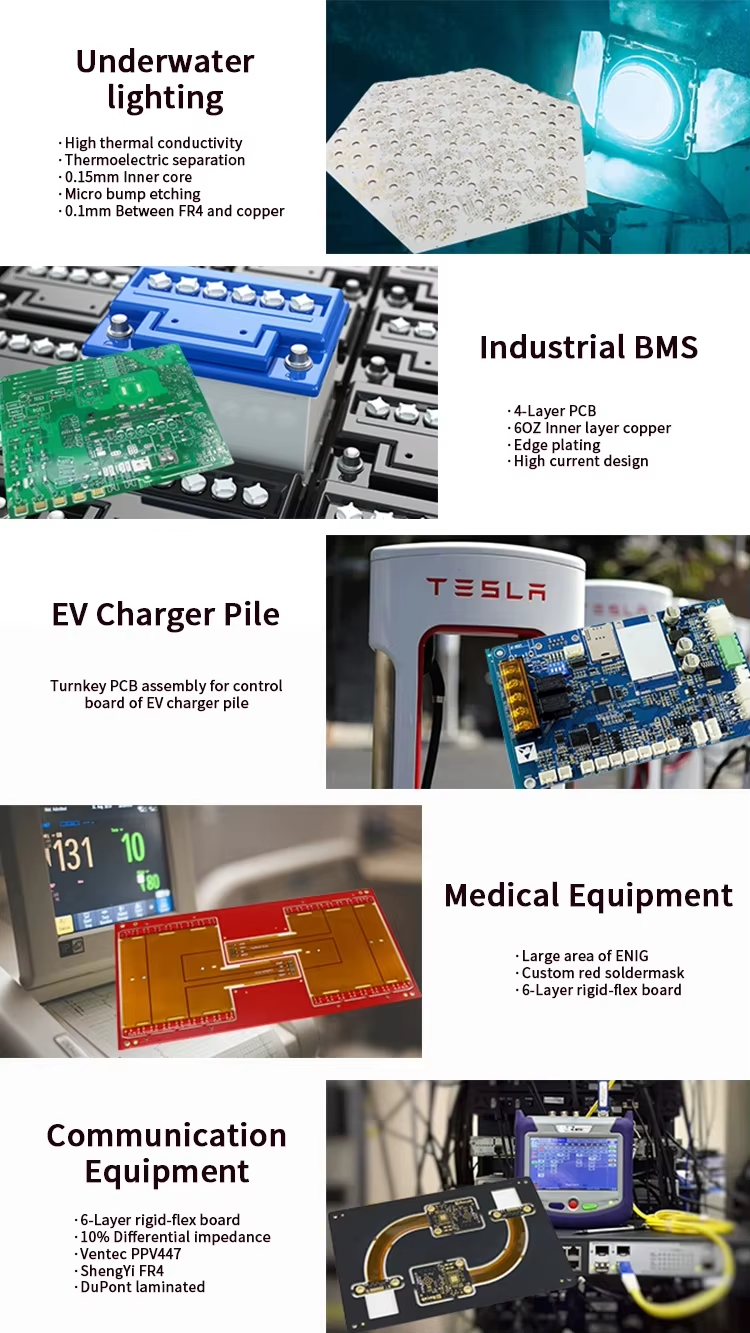

PCB Showcase

PCBA Abilities

Item | PCBA Abilities |

Turnkey Service | PCB Design + PCB FAB + Components Sourcing + PCB Assembly + Package |

Value-Added Services | BOM Analysis, Conformal Coating, IC Programming, Wire Harness & Cable Assembly, Box Building |

Assembly Details | 5 SMT + 2 DIP (Dust and anti-static lines) |

Assembly Abilities | SMT 5 million points per day DIP 10 thousands pieces per day |

Technical Support | Free DFM/A check, BOM analysis |

Handing Standards | IPC-A-600H, IPC-A-610F, J-STD-001F |

MOQ | 1 piece |

Inspection & Testing | Visual Inspection, AOI, SPI, X-ray inspection. First article inspection for each process. |

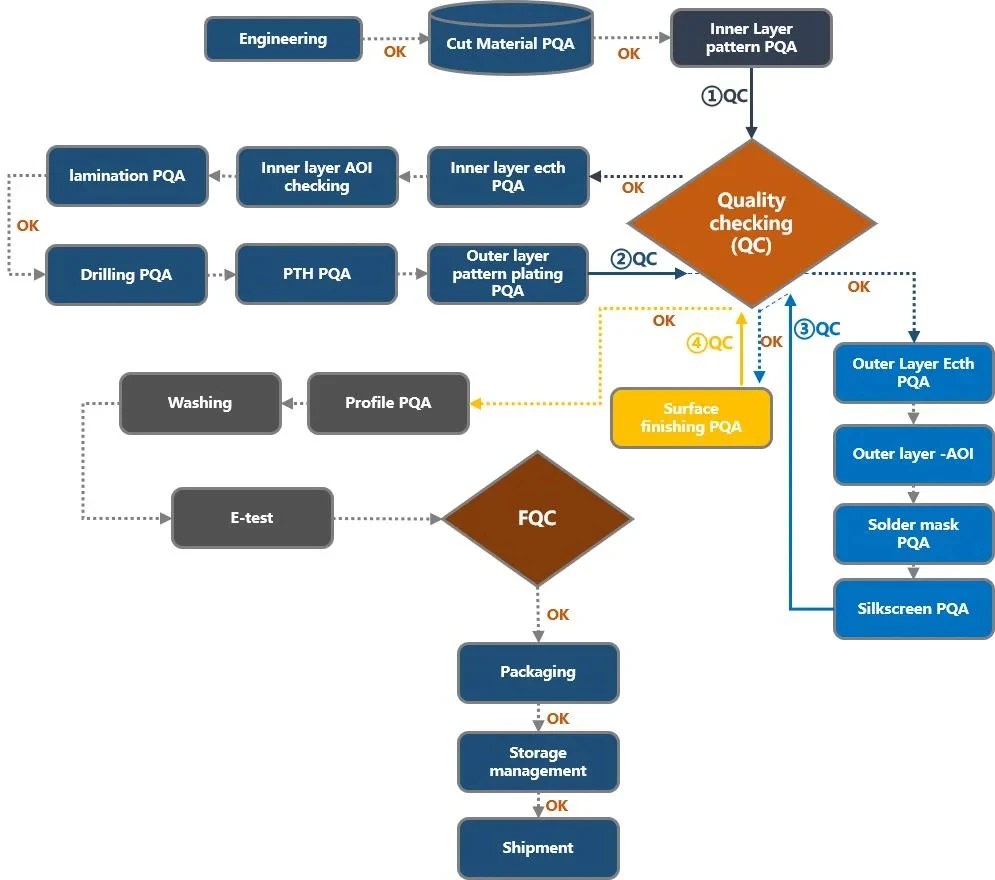

IQC + IPQC + FQC + OQC Inspection Flow | |

Flying probe test/In-circuit test/Function test/Burn-in test | |

Files We Need | PCB: Gerber (CAM, PCB, PCBDOC) |

Components: Bill of Material (BOM list) | |

Assembly: Pick-and-Place file | |

Functional test: Test Guide | |

PCB Panel Size | Min: 0.25×0.25 inches (6×6mm) |

Max: 20×20 inches (500×500mm) | |

PCB Solder Type | Water soluble solder paste, RoHS lead-free |

PCB Assemble Methods | SMT, THT & Hybrid, single or double side placement, Part removal and replacement. |

Components Details | Passive down to 0201 (01005) size |

Press fit connectors | |

QFP/BGA/LGA/QFN/COB/COF | |

CSP/WLCSP/POP | |

Fine Pitch High Pin Count Connectors | |

BGA repair and reball | |

Lead Time | Prototype: 5-15 working days; Mass production: 20~25 working days. The fastest delivery time is 3 days. |

Packaging | Anti-Static Bags/Customized Packaging |

PCBA Showcase

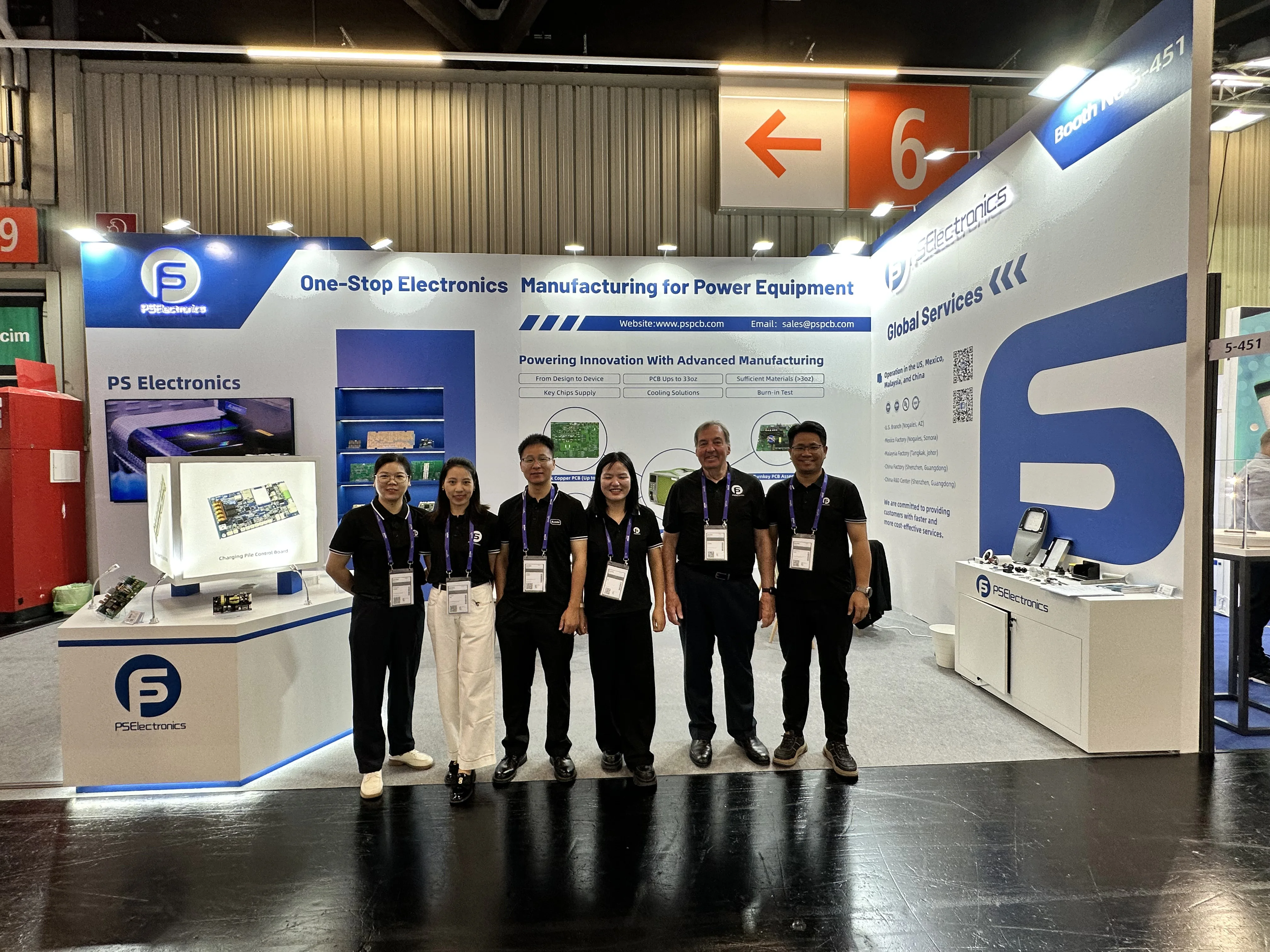

Company Profile

One-Stop OEM PCB Assembly Professional Turnkey PCBA

Pinsheng Electronics started to provide contract electronics design and manufacturing services in 2008, we are obsessed withproviding the happiest manufacturing experience to our customers.

When our founders found it difficult to get technical support and always high-quality products from the manufacturers, they sprouted the vision to provide blissful electronics manufacturing services to others, they rented an old workshop and started the journey.

When our founders found it difficult to get technical support and always high-quality products from the manufacturers, they sprouted the vision to provide blissful electronics manufacturing services to others, they rented an old workshop and started the journey.

In over 15 years, with the same vision, we have designed, manufactured, and delivered 5,000+ projects for over 2,000 SMEs. The products are alive to us, not lifeless pieces of stuff.

Main Customers

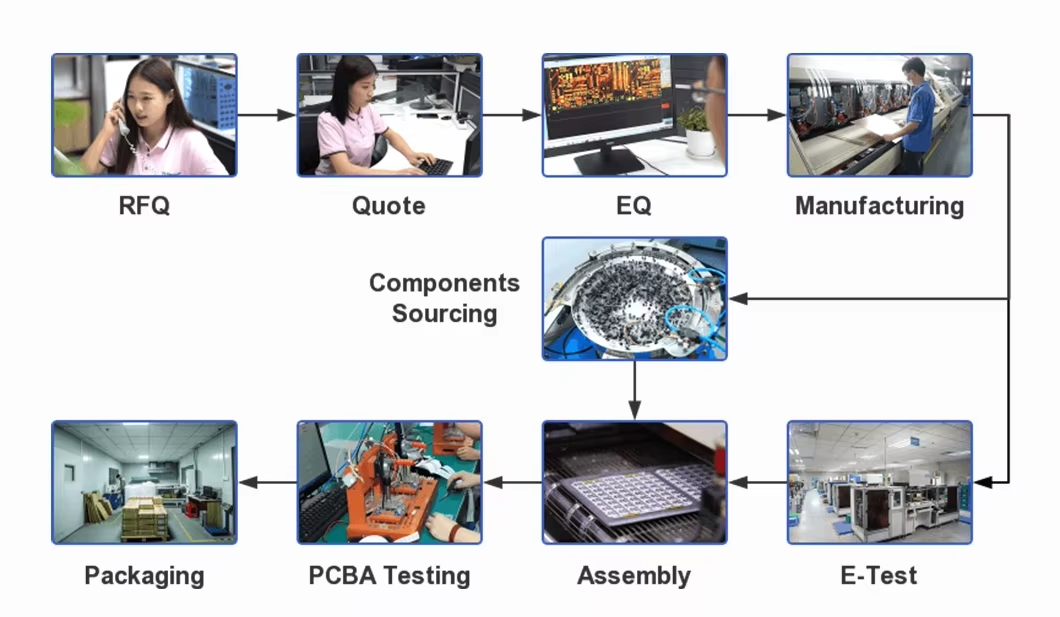

Ordering Process

Cases

Certifications

ISO 9001

ISO 14001

REACH

ROHS

UL CANADA

SMT & DIP Workshop

Quality And Policy:

Continually improve our quality, efficiency, service to satisfy thecustomer's requirement.

Quality System:

1. ISO-9001:2018 Quality System Standard

2. ISO14001 Environment System Standard

3. Quality Standard: IPC-610-D class 2,

4. Soldering Standard: J-STD-001 class 1,2,3

5. ESD Standard: ESD-MIL-STD-1686

6. Workshop management:5S

7. FAI-first article inspection

8. In process visual inspection

9. AOI inspection

10. X-ray Inspection

11. SPI Inspection

12. Machine calibration and preventative maintenance

13. ERP material and process management ( ERP=enterprise resource planning computer system)

Quality standards:

IPC-A-610D-G

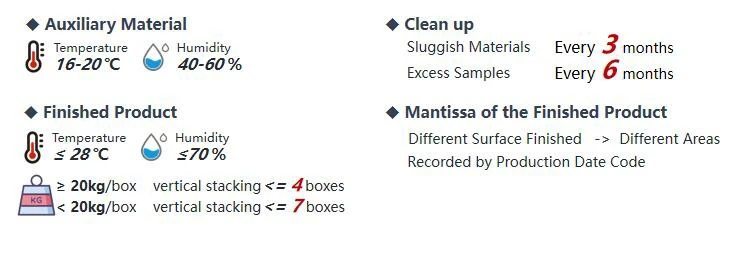

Material Control

Continually improve our quality, efficiency, service to satisfy thecustomer's requirement.

Quality System:

1. ISO-9001:2018 Quality System Standard

2. ISO14001 Environment System Standard

3. Quality Standard: IPC-610-D class 2,

4. Soldering Standard: J-STD-001 class 1,2,3

5. ESD Standard: ESD-MIL-STD-1686

6. Workshop management:5S

7. FAI-first article inspection

8. In process visual inspection

9. AOI inspection

10. X-ray Inspection

11. SPI Inspection

12. Machine calibration and preventative maintenance

13. ERP material and process management ( ERP=enterprise resource planning computer system)

Quality standards:

IPC-A-610D-G

Material Control

Material Brand | ShengYi, NanYa, ITEQ, Ventec, etc |

Regular Thickness | 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm |

Normal Size (FR4 Sheet) (length x width mm) | 1220x914, 1220x1016, 1220x1066 1232x927, 1295x1092, 1280x1080 1245x940, 1245x1041, 1245x1092 |

Normal Size (MCPCB Sheet) (length x width mm) | 1000x1200, 1050x1250 |

Key inspection items | 1.Manufacturer Brand; 2.Material certificate; 3.Appearance of the material; 4.Dimension; 5.Sample checking. |

The qualified material must be marked with the relevant material inspection certificate, then qualified material will be saved to

warehouse.

#Quality Assurance

warehouse.

#Quality Assurance

Production Control

#Main Person in Production Workshop:

-Technical Manager

>= 3 years of relevant work experience

-Engineers

>= 5 years of relevant work experience

Be fluent in English

Familiar with PCB circuit layout and design software (Altium, Protel, PowPCB)

Master PCB manufacturing and fabrication process

-New employees

Need to pass the Pre-job training

-Technical Manager

>= 3 years of relevant work experience

-Engineers

>= 5 years of relevant work experience

Be fluent in English

Familiar with PCB circuit layout and design software (Altium, Protel, PowPCB)

Master PCB manufacturing and fabrication process

-New employees

Need to pass the Pre-job training

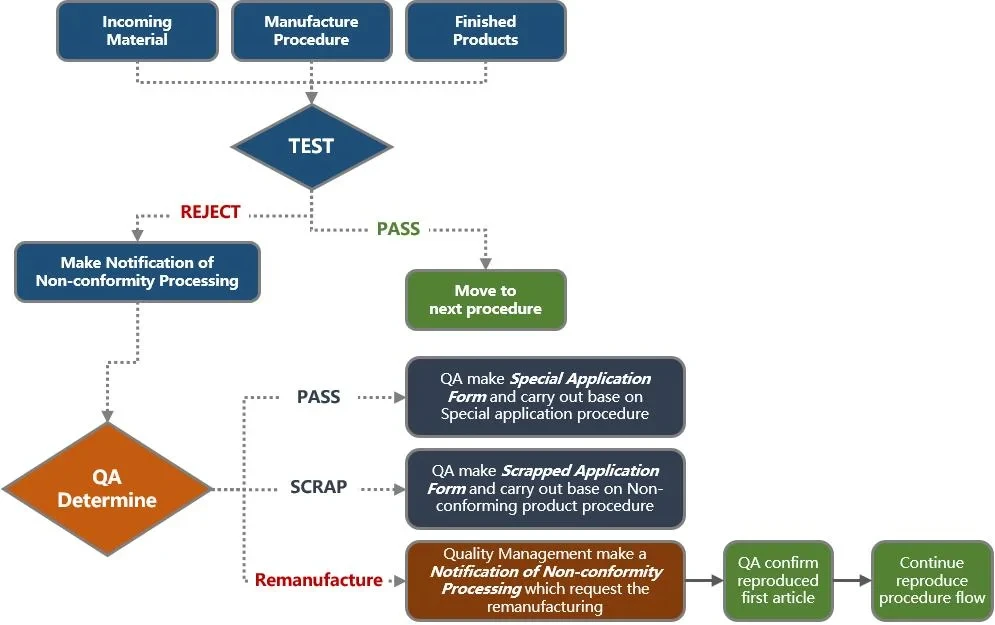

#Unqualified Control Process

Regarding the management of non-conforming products in the production process, our company strictly follows the "non-conforming

product management procedures".

Quality control department,

Engineering department,

Production department,

QA department,

Business department

are responsible for resolving problems together.

Regarding the management of non-conforming products in the production process, our company strictly follows the "non-conforming

product management procedures".

Quality control department,

Engineering department,

Production department,

QA department,

Business department

are responsible for resolving problems together.

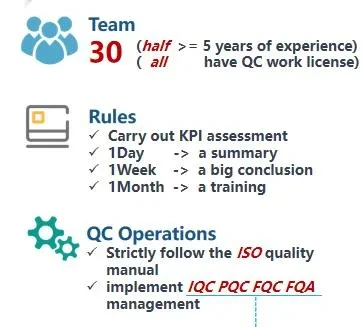

IQC (Incoming Quality Control)

PQC (Process Quality Control)

First Article Inspection, PQC will go to each production machine for inspection every 2-4 hours (size, appearance).

Quality management of semi-finished products in each process. We will send 2-5pcs semi-finished boards of each shift to the quality inspector until they confirm then continue production.

Operator charge the quality inspection for the subsequently semi-finished boards, sign confirmation after approved. Quality inspector random inspections. Only they are qualified can be handed over to the next process.

FQC (Final Quality Control)

(That is the finished product inspection before shipment), appearance inspection 100%, random inspections of board dimension by batch.

FQA (Final Quality Assurance)

According to the inspection standards of FQC sampling verification, and finally control quality, and then double guarantee the PCB quality.

PQC (Process Quality Control)

First Article Inspection, PQC will go to each production machine for inspection every 2-4 hours (size, appearance).

Quality management of semi-finished products in each process. We will send 2-5pcs semi-finished boards of each shift to the quality inspector until they confirm then continue production.

Operator charge the quality inspection for the subsequently semi-finished boards, sign confirmation after approved. Quality inspector random inspections. Only they are qualified can be handed over to the next process.

FQC (Final Quality Control)

(That is the finished product inspection before shipment), appearance inspection 100%, random inspections of board dimension by batch.

FQA (Final Quality Assurance)

According to the inspection standards of FQC sampling verification, and finally control quality, and then double guarantee the PCB quality.

Test and Maintenance Workshop

Test and Maintenance Workshop

STHL provide custom test service according to client's requirements and products. Usually STHL PCBA Tech

offers a full range of testing service. Including:

*AOI (Automatic Optical Inspection)

* Function Testing

* In Circuit Testing

* Testing Fixtures

* Testing Service

* X-Ray for BGA Testing

* Printing Solder Paste Test

Each board is carefully examined by our dedicated inspection team using AOI and high magnification viewers.

Using our X-Ray machine, we test PCBs to component level and all wiring is fully inspected and tested. Flash

testing and earth bonding tests can also be undertaken where required.

offers a full range of testing service. Including:

*AOI (Automatic Optical Inspection)

* Function Testing

* In Circuit Testing

* Testing Fixtures

* Testing Service

* X-Ray for BGA Testing

* Printing Solder Paste Test

Each board is carefully examined by our dedicated inspection team using AOI and high magnification viewers.

Using our X-Ray machine, we test PCBs to component level and all wiring is fully inspected and tested. Flash

testing and earth bonding tests can also be undertaken where required.

Warehouse Management

Regarding warehouse management, we will divide different areas according to different customers and place customers' products

neatly.

And the warehouse administrator will responsible for managing, and ensure the records for outbound and inbound, we strictly follow

the Warehousing Requirement Documents to manage all the goods.

neatly.

And the warehouse administrator will responsible for managing, and ensure the records for outbound and inbound, we strictly follow

the Warehousing Requirement Documents to manage all the goods.

Packing & Delivery

FAQ

Q1: What's your monthly capacity of PCB assembly

A: Monthly 140 million points from SMT, 300K pieces from DIP.

Q2: How do you go quality control in PCB assembly?

A: We fully comply with ISO requirements and process in accordance with the Quality Management Manual for order management, production management, and process management, and strictly implement processes such as corrective and preventive measures and change management.

Q3: Can you source parts for me even if no assembly need?

A: Absolutely please provide us with your BOM or a list we will analyze the source make classified packaging attached with labels then send them to you.

Q4: What is your components procurement capability? Which supplier do you work with directly?

A: We have more than 40,000 part models in stock, and provide you with hard-to-get chip supply. Our parts are directly from the top level suppliers such as Microchip, TI, ARROW, AVNET, FUTURE, ELMENT, Digikey...

Q5: How do you go inventory management?

A: According to ISO process warehouse management operation guideline, we observe the principle of first-in-first-out of materials, and control the temperature (constant 25°C) and humidity (40% RH) of the warehouse with strict anti-static. Stock materials are managed separately according to different customers.

Q6: How are EOL (End of Life) materials handled? Is it possible to provide the successful case of replacing EOL material?

1. If EOL happens in the running projects, the agent will send a production stoppage notice (Order & Supply deadline), and then our clients will get notified with our alternative suggestions.

2. For the projects transferred from other production source, we will source alternatives in advanced, or come up with and help our clients to change the design if no exact match alternatives.

3. For other cases, we will try to meet the short-term needs of customers based on our understanding of the market inventory situation.

Q7: Do you provide IC programming and fixture creation?

A: IC programming is available for all of our customers, please provide the guidelines and software, it can be done by IC burner or motherboard burn-in. We can make the fixtures as customers' requirements.

Q8: What test methods do you provide?

A: The boards will go through AOI, X-ray, default circuit testing, function testing in regular, and more testing as required.

Q9: What's the lead time?

A: It depends on the quantity and BOM. For usual small batches, it takes about 3-5 weeks, when it comes to mass production for forecast orders, we will schedule the production about 10-12 weeks before delivery.

Q10: How do you ensure delivery on time?

A: We generally guarantee delivery within 5 days after the material is ready (except for rush orders), our measures include:

1. receiving and verifying the files prior to quotation;

2. ensuring all the materials get ready on time and be checked at the same time;

3. making PCB boards and stencil according to Gerber first;

4. communicate in time when prototyping is running to ensure that problems are handled on the same day.

A: Monthly 140 million points from SMT, 300K pieces from DIP.

Q2: How do you go quality control in PCB assembly?

A: We fully comply with ISO requirements and process in accordance with the Quality Management Manual for order management, production management, and process management, and strictly implement processes such as corrective and preventive measures and change management.

Q3: Can you source parts for me even if no assembly need?

A: Absolutely please provide us with your BOM or a list we will analyze the source make classified packaging attached with labels then send them to you.

Q4: What is your components procurement capability? Which supplier do you work with directly?

A: We have more than 40,000 part models in stock, and provide you with hard-to-get chip supply. Our parts are directly from the top level suppliers such as Microchip, TI, ARROW, AVNET, FUTURE, ELMENT, Digikey...

Q5: How do you go inventory management?

A: According to ISO process warehouse management operation guideline, we observe the principle of first-in-first-out of materials, and control the temperature (constant 25°C) and humidity (40% RH) of the warehouse with strict anti-static. Stock materials are managed separately according to different customers.

Q6: How are EOL (End of Life) materials handled? Is it possible to provide the successful case of replacing EOL material?

1. If EOL happens in the running projects, the agent will send a production stoppage notice (Order & Supply deadline), and then our clients will get notified with our alternative suggestions.

2. For the projects transferred from other production source, we will source alternatives in advanced, or come up with and help our clients to change the design if no exact match alternatives.

3. For other cases, we will try to meet the short-term needs of customers based on our understanding of the market inventory situation.

Q7: Do you provide IC programming and fixture creation?

A: IC programming is available for all of our customers, please provide the guidelines and software, it can be done by IC burner or motherboard burn-in. We can make the fixtures as customers' requirements.

Q8: What test methods do you provide?

A: The boards will go through AOI, X-ray, default circuit testing, function testing in regular, and more testing as required.

Q9: What's the lead time?

A: It depends on the quantity and BOM. For usual small batches, it takes about 3-5 weeks, when it comes to mass production for forecast orders, we will schedule the production about 10-12 weeks before delivery.

Q10: How do you ensure delivery on time?

A: We generally guarantee delivery within 5 days after the material is ready (except for rush orders), our measures include:

1. receiving and verifying the files prior to quotation;

2. ensuring all the materials get ready on time and be checked at the same time;

3. making PCB boards and stencil according to Gerber first;

4. communicate in time when prototyping is running to ensure that problems are handled on the same day.