PET HDPE ABS PP Automatic Plastic Preform and Lid Injection Molding Machine Price

US $19,000.00 / set

1 set(s)Minimum order

plastic processed:

PP, PC, PET, PVC, PPR, MLLDPE, EVA, HDPE

style:

Horizontal

distance between tie bars(width)(mm):

460mm

distance between tie bars(height)(mm):

460mm

plasticizing capacity(g/s):

256

mold height(mm):

180 - 500 mm

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PP, PC, PET, PVC, PPR, MLLDPE, EVA, HDPE |

|---|---|

| style | Horizontal |

| distance between tie bars(width)(mm) | 460mm |

| distance between tie bars(height)(mm) | 460mm |

| plasticizing capacity(g/s) | 256 |

| mold height(mm) | 180 - 500 mm |

| ejector number | 5 |

| ejector stroke(mm) | 436 mm |

| ejector force(kn) | 140 kN |

| theoretical shot volume(cm³) | 814 cm³ |

| injection rate (g/s) | 270 g/s |

| machine type | Hydraulic |

| injection weight (g) | 830 g |

| screw diameter (mm) | 62 mm |

| screw l/d ratio | 24 |

| weight (kg) | 6000 kg |

| place of origin | zhejiang,taizhou |

| open stroke(mm) | 426 mm |

| model number | ZG-001 |

| brand name | ZEGO machine |

| power (kw) | 22 kW |

| warranty | 1 Year |

| key selling points | Multifunctional |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | PLC, motor |

| Product name | PET plastic injection molding machine |

| BRAND | ZEGO |

| Condition | New |

| Type | Injection Blow Molding |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Food Shop |

| Showroom Location | Canada, United Kingdom, Mexico |

| Warranty of core components | 1 Year |

Product Detail

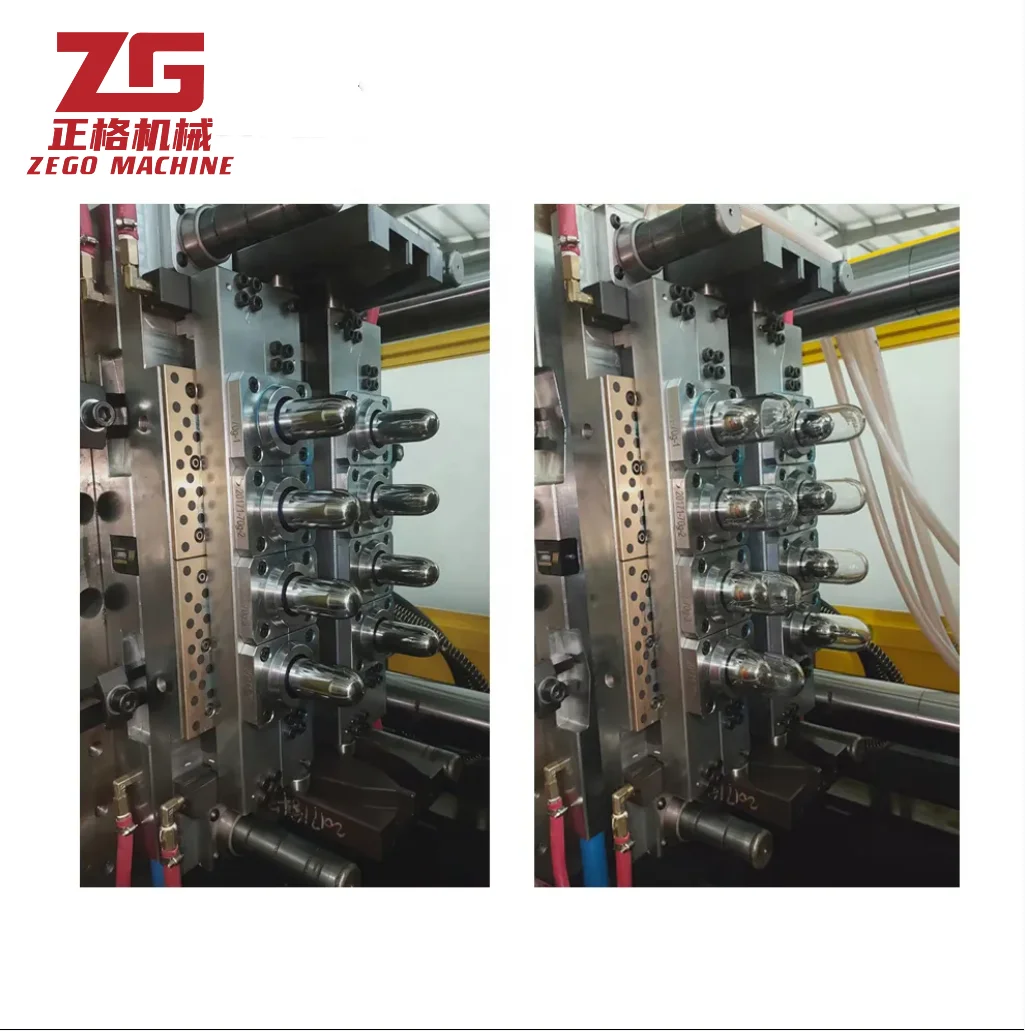

ZEGO ZG-320PET injection molding machine is designed for beverage bottles, floating balls and other use of PET preform. Special plasticized system, high efficiency plasticization, make the glue color clear and uniform.

Technical Parameter | GF260PET | GF320PET | GF400PET | ||

Screw Diameter | mm | 60 | 67 | 90 | |

Max. Shot Weight(PS) | g | 965 | 1074 | 3099 | |

Injection Pressure | Mpa | 168 | 174 | 145 | |

Clamping Force | KN | 2600 | 3200 | 4000 | |

Opening Stroke | mm | 550 | 630 | 720 | |

Space Between Tie Bars(W*H) | mm | 590*590 | 662*615 | 740*700 | |

Max. Mold Height | mm | 600 | 650 | 720 | |

Min. Mold Height | mm | 220 | 250 | 340 | |

Hydaulic System Pressure | Mpa | 16 | 17.5 | 17.5 | |

Machine Dimensions(L*W*H) | m | 6.1*1.5*2.36 | 6.9*1.8*2.4 | 7.5*1.7*2.5 | |

Digital control system uses a dedicated controller, multiple CPU processing units, a multi-function automatic fault detection,alarm system, can verify 99 processing program molds, and has a remote control interface.

Infrared heating, fast temperature rise and good thermal insulation effect.Stable machine performance and high energy saving rate.

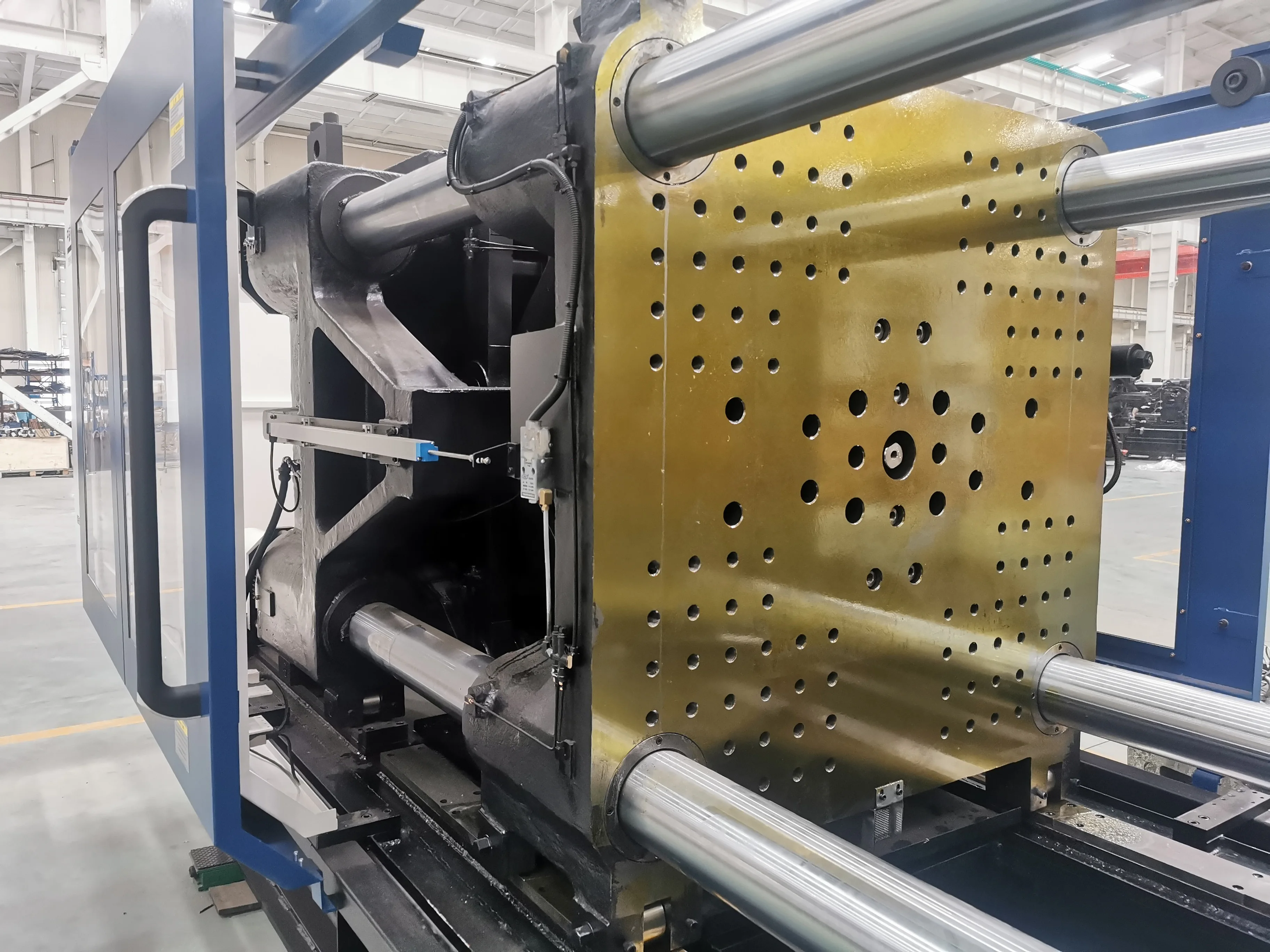

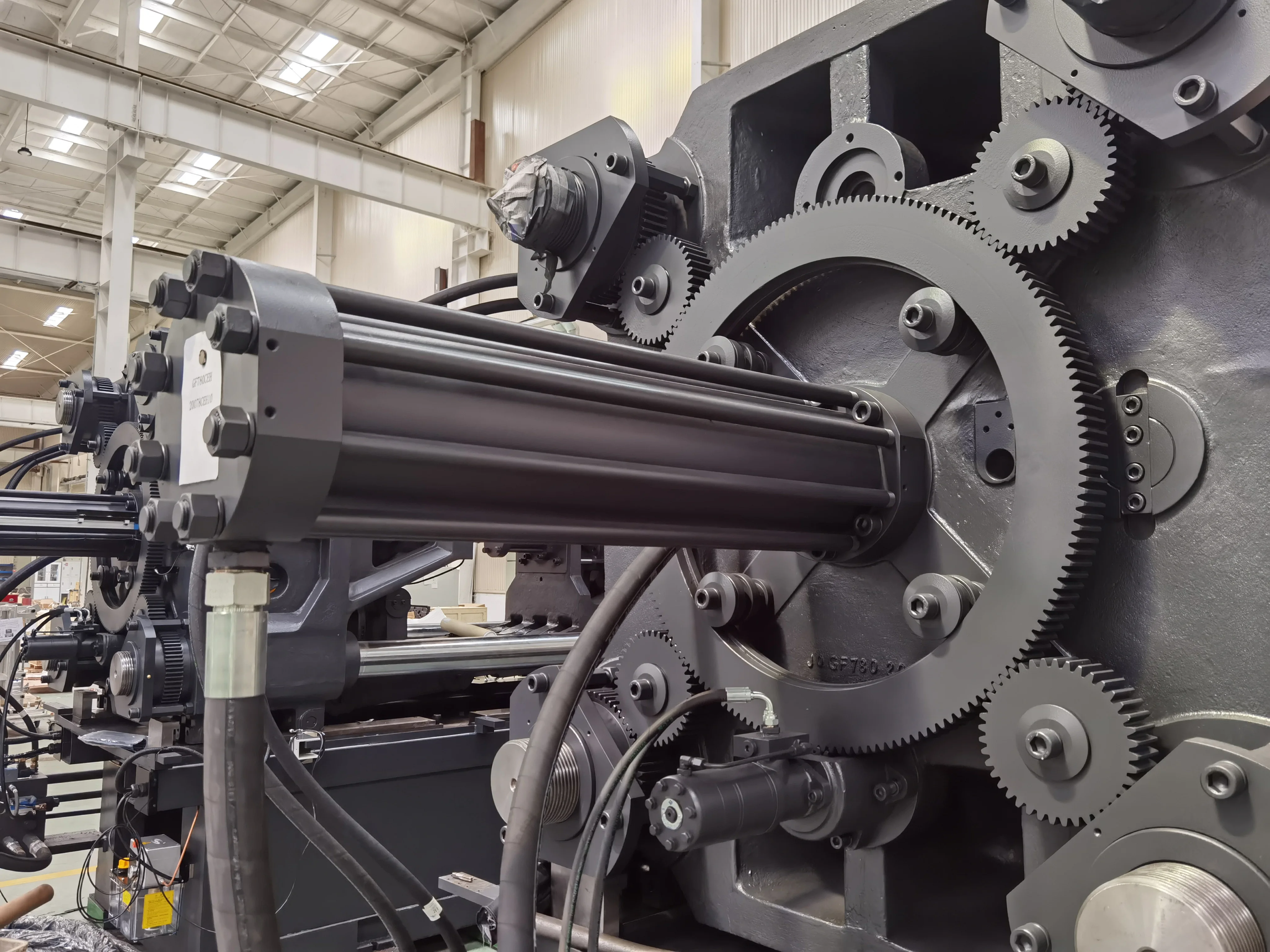

The tie rods are made of high quality structural alloy steel plated with hard chromium, with high mechanical strength and fatigue strength.

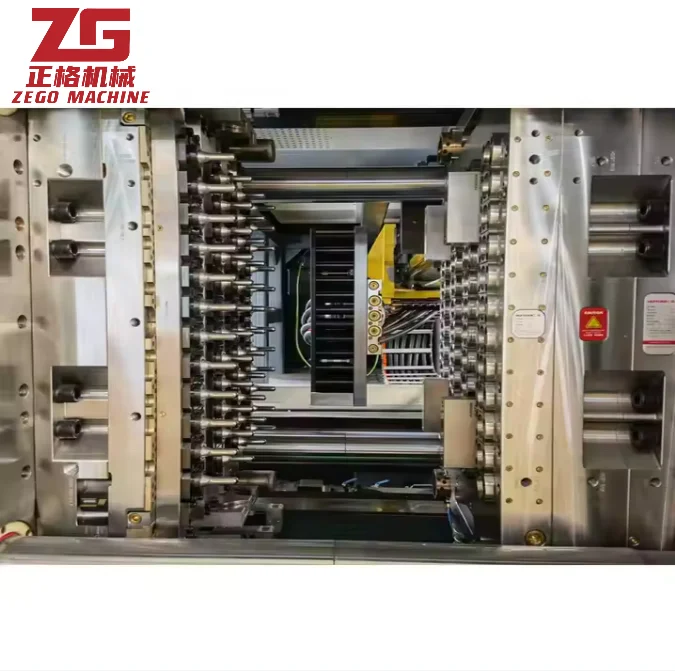

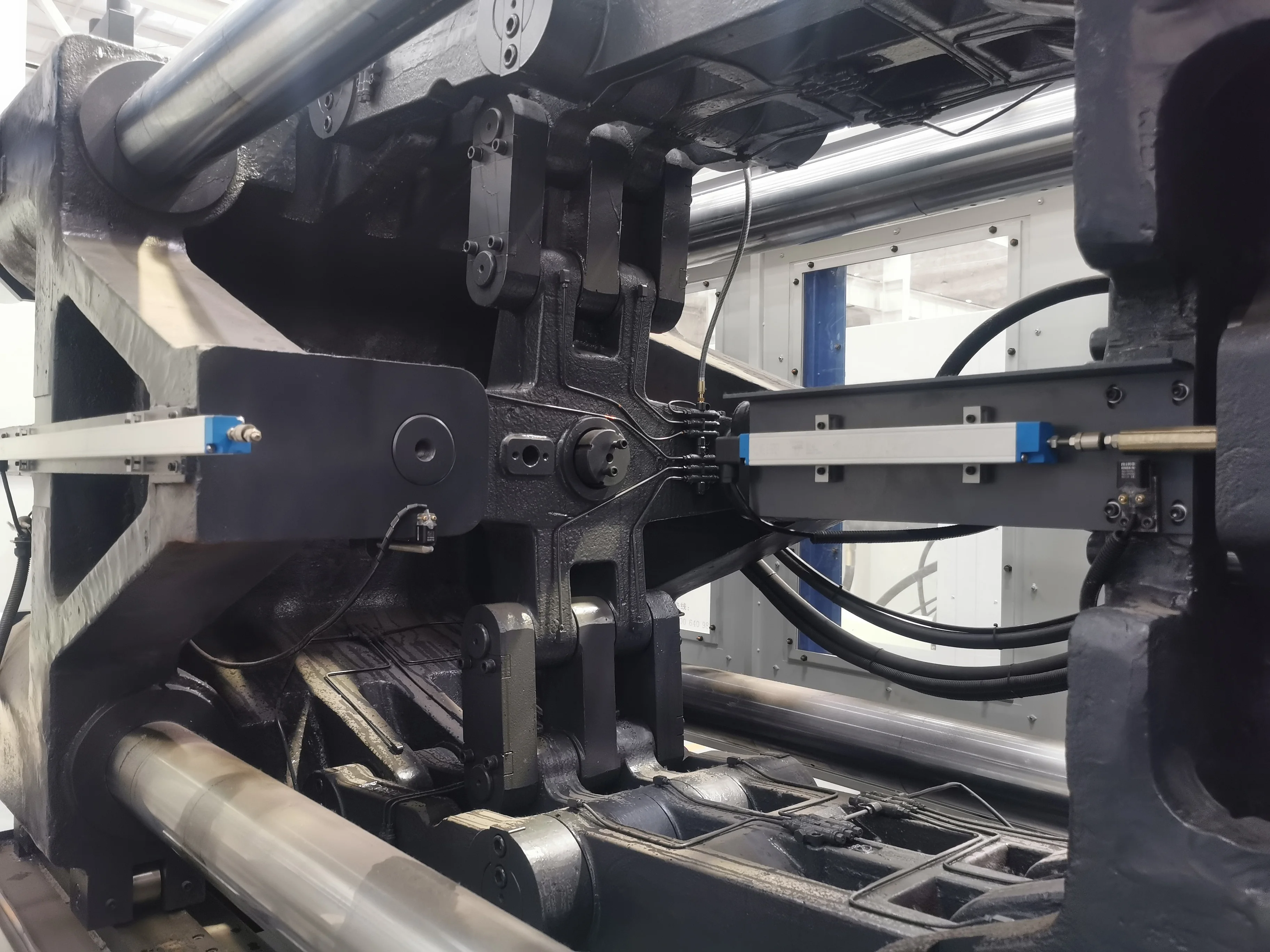

With double guide posts and dual-cylinder balance injection device, guarantees that balanced and uniform forces are applied on the screw during injection and moving forward.

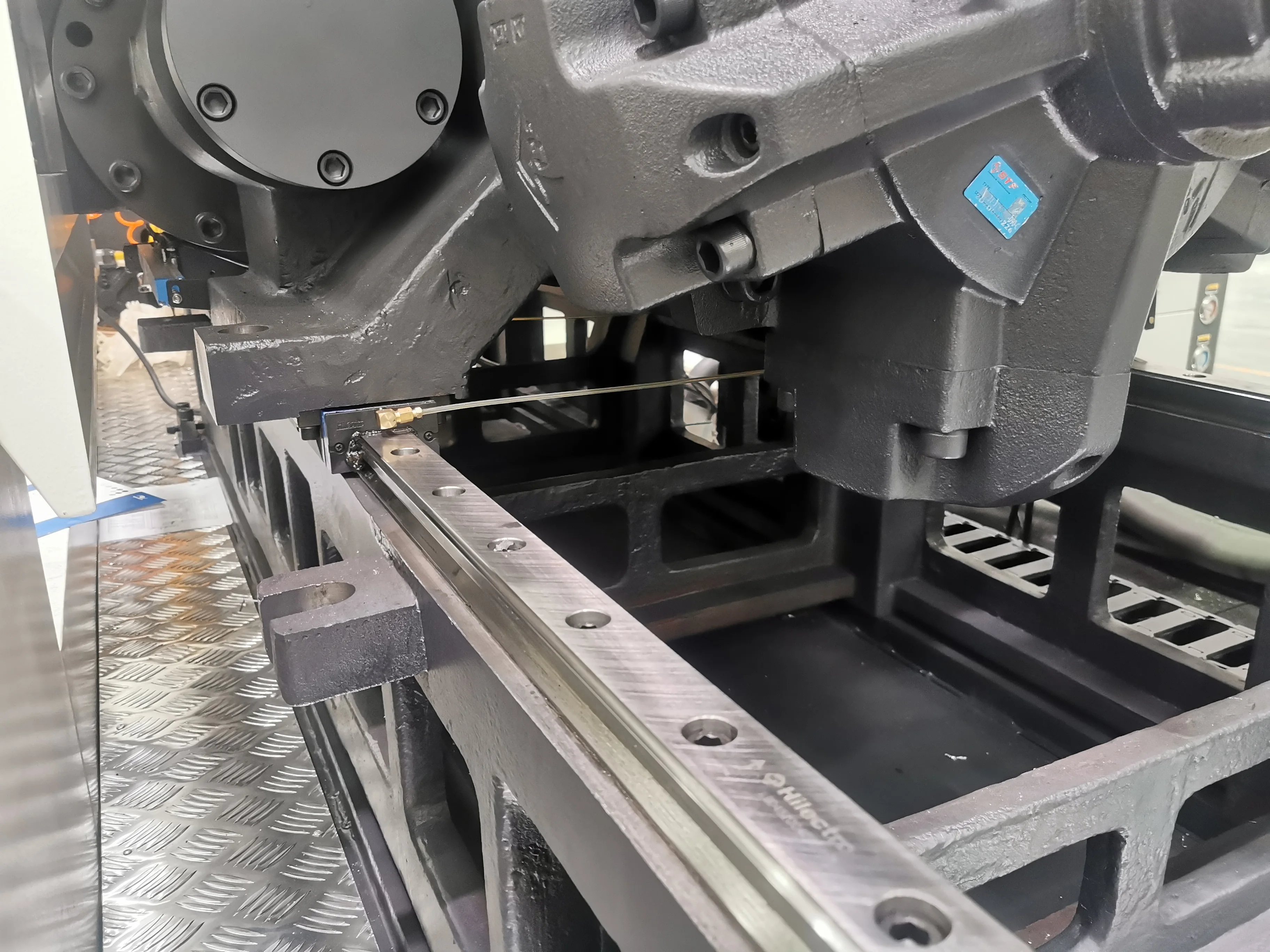

High-precision electronic detection device, multi-level control of travel, speed and position, positioning accuracy.The safety door is equipped with a triple safety device of hydraulic, mechanical and electrical interlock.

Multi stages controlling of mold clamp pressure, speed and position.Mold thickness can be adjusted through ring gear which is driven by hydraulic oil motor.

Bottle Making Machine

Bottle Preform

Preform Mold

Bottle

Verification Certificates of equipment:lSO9001:2001; CE Certificate,SGS-COC,TUV National Certificate of equipment

verification:standard organisation of Nigeria,CNCA certificate,Logo trademark registration,etc.

verification:standard organisation of Nigeria,CNCA certificate,Logo trademark registration,etc.

Work shop

Customer Trust

1.YOU ARE WELCOME TO OUR FACTORY AT ANY TIME. If we can full fill your request and you interested in our products, you may pay a visit to ZEGO Machine site.The meaning of visiting supplier, because seeing is believing,

2.Q: ARE YOU A FACTORY OR TRADING COMPANY?

A: We are a factory directly supplier. ZEGO Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

3. Q: DO YOU PROVIDE BOTTLE BLOW MOULD AND AIR COMPRESSOR ?

A: Yes, we provide complete system and you will no need to find the suitable air compressor and chiller.... etc

4.Q: WHAT IS THE LANGUAGE OF THE PLC AND TOUCH PANEL?

A: Don't worry, we will translate the language in English,Spanish or any other language to make sure you will have an easy

operation.

5.Q: HOW To GUARANTEE YOUR FUNDS To BE SAFE AND DELIVERY To BE ON TIME?

A:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to

buy.By letter of credit, you can lock the delivery time easily.. After the factory visit, You can ensure the facility of our bank

account.

6.Q:ZEGO MACHINE HOW To ENSURE THE QUALITY?

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years.After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

7.Q:THE AFTER-SALE SERVICE OF ZEGO MACHINE?

A:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and

training.Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

2.Q: ARE YOU A FACTORY OR TRADING COMPANY?

A: We are a factory directly supplier. ZEGO Machine with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

3. Q: DO YOU PROVIDE BOTTLE BLOW MOULD AND AIR COMPRESSOR ?

A: Yes, we provide complete system and you will no need to find the suitable air compressor and chiller.... etc

4.Q: WHAT IS THE LANGUAGE OF THE PLC AND TOUCH PANEL?

A: Don't worry, we will translate the language in English,Spanish or any other language to make sure you will have an easy

operation.

5.Q: HOW To GUARANTEE YOUR FUNDS To BE SAFE AND DELIVERY To BE ON TIME?

A:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to

buy.By letter of credit, you can lock the delivery time easily.. After the factory visit, You can ensure the facility of our bank

account.

6.Q:ZEGO MACHINE HOW To ENSURE THE QUALITY?

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years.After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

7.Q:THE AFTER-SALE SERVICE OF ZEGO MACHINE?

A:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the installation and

training.Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.