Pilot Brewing System Nano Brewery Beer Brewing Equipment 1bbl 2bbl 3bbl 4bbl 5bbl Brewhouse System

US $10,000.00 / set

1 set(s)Minimum order

processing:

Fermenting Equipment

place of origin:

Shandong, China

brand name:

Meto

processing types:

Beer

voltage:

380V/50Hz

power(w):

0-80kw

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| processing | Fermenting Equipment |

|---|---|

| place of origin | Shandong, China |

| brand name | Meto |

| processing types | Beer |

| voltage | 380V/50Hz |

| power(w) | 0-80kw |

| dimension(l*w*h) | various in different tank |

| weight | 2000 KG |

| warranty | 5 years |

| Machinery Capacity | according to tank |

| machinery test report | Provided |

| core components | Pump, Pressure vessel, PLC |

| key selling points | Competitive Price |

| video outgoing-inspection | Provided |

| Key words | Beer equipment |

| Capacity | 1bbl 2bbl 3bbl 4bbl 5bbl |

| Material | Stainless Steel 304/316 |

| Application | Brewpub Beer Brewery Restaurant |

| Brewhouse | Two vessels or three vessels brewhouse |

| Thickness of Tanks | Inner 3mm/external 2mm |

| Technology | Offer Auto Cad and 3D design drawing |

| Heating method | Steam Electric Fire |

| Inner Polishing Precision | 0.4um |

| Control system | PID or PLC controller |

| Applicable Industries | hotels, Manufacturing Plant, Food & Beverage Factory, Restaurant, Retail, Food & Beverage Shops |

| Showroom Location | United States, Italy, France, Germany, Mexico, Russia, Argentina, Chile, Colombia, South Africa |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | Ordinary Product |

Product Detail

8bbl stainless steel fermentation tank beer making equipment

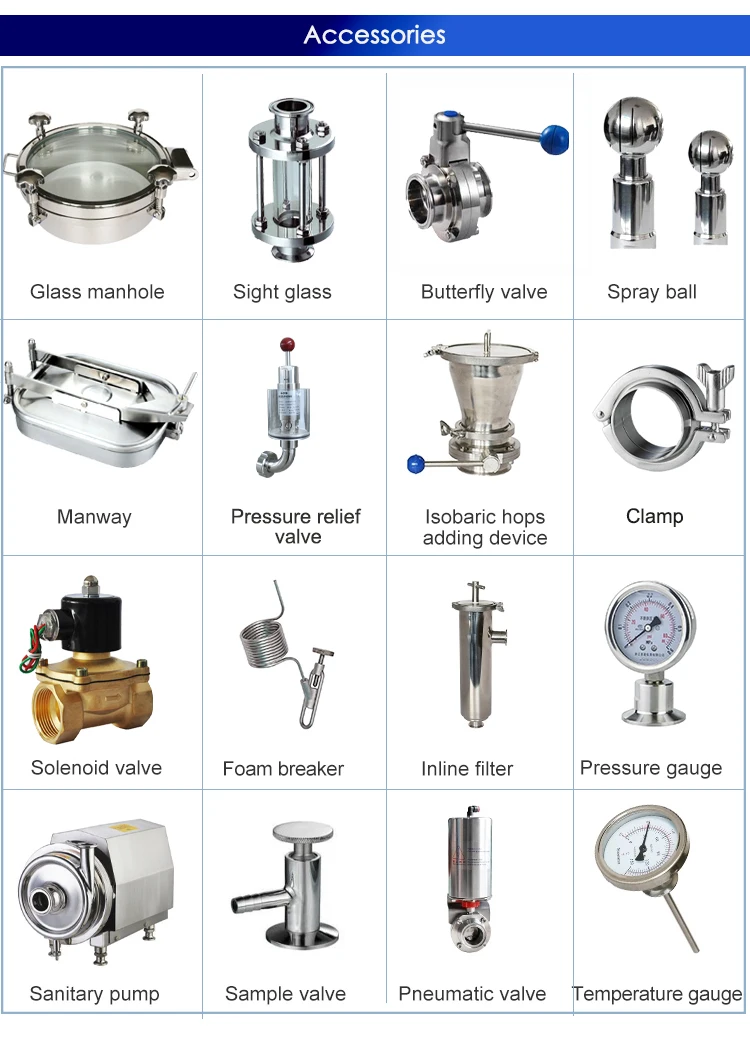

1.METO Beer Equipment Components

Main Part | Components |

Milling System | 1.Miller |

Heating System | 1.Steam Boiler (Optional) 2.Direct fire (Optional) 3.Electric Heating (Optional) |

Brewhouse System | 1.Mash Tun/Lauter Tank + Brew Kettle/Whirlpool Tank(2 vessel) 2. Mash Tun/Lauter Tank + Brew Kettle + Whirlpool Tank(3 vessel) 3. Mash Tun + Lauter Tank + Brew Kettle/Whirlpool Tank(3 vessel) 4. Mash Tun + Lauter Tank + Brew Kettle + Whirlpool Tank(4 vessel) |

Fermentation System | 1.Fermentation Tank 2.Bright beer Tank |

Cooling System | 1.Cold Water tank 2.Cooling Unit |

Cleaning System | 1.Disinfection Tank 2.Alkali Tank |

Control System | 1.PID (optional) 2.PLC (optional) |

2.METO Brewhouse System

Advantages of brewhouse:

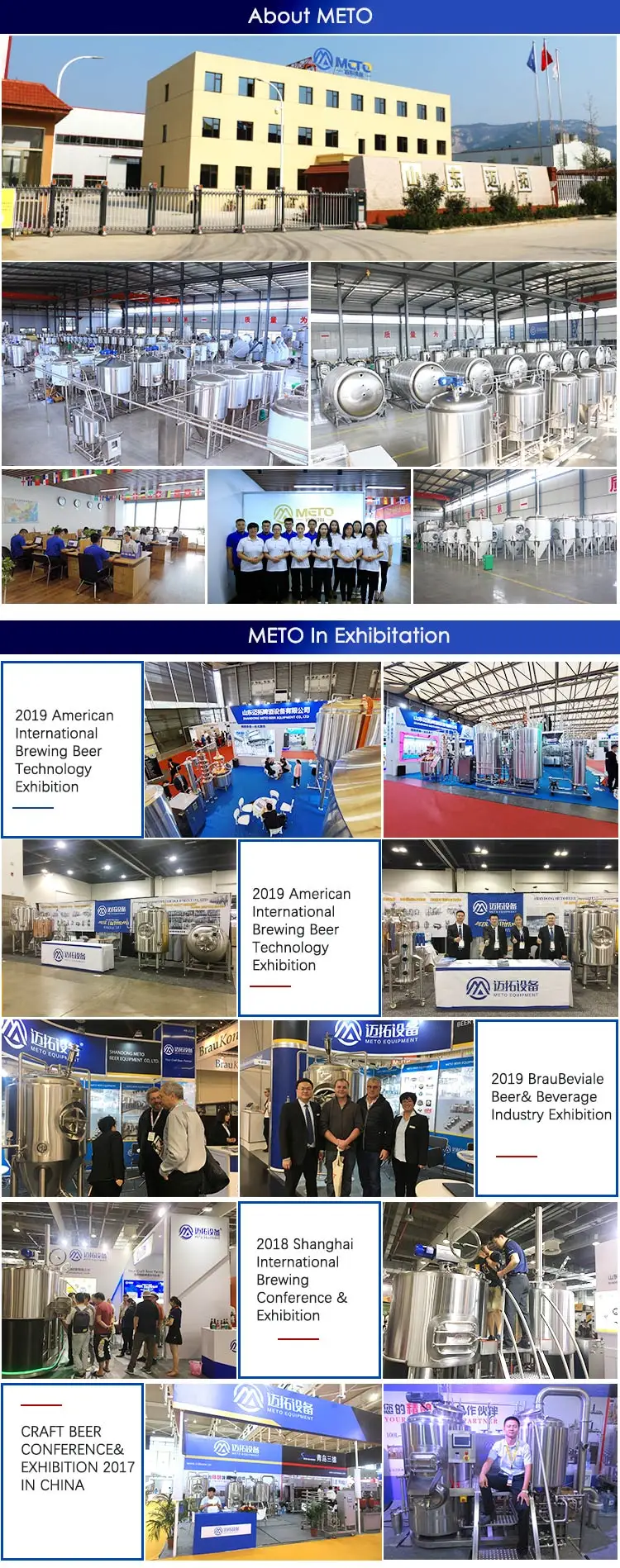

METO Craft Beer Equipment absorbs the mature, advanced beer brewing technology from Europe and USA , and upgrades and improves the technology to meet different needs on taste, production or process.

Depends on different productions 100L-5000L, it can be divided three series, 20 kinds of specifications.Maximize your brewhouse’s efficiency with our systems!

METO’s professional beer equipment engineer also can provide Personalized services, according to your demand.Choose State-of-the-Art 2, 3 and 4 Vessel Brewing Systems,whether you want to save space, money, and time by only using a 2 vessel mash and boil kettle or other requirement, we can provide you with the best solution.

Depends on different productions 100L-5000L, it can be divided three series, 20 kinds of specifications.Maximize your brewhouse’s efficiency with our systems!

METO’s professional beer equipment engineer also can provide Personalized services, according to your demand.Choose State-of-the-Art 2, 3 and 4 Vessel Brewing Systems,whether you want to save space, money, and time by only using a 2 vessel mash and boil kettle or other requirement, we can provide you with the best solution.

3.METO Fermentation Tanks

Fermentation Tank Capacity | Volume in US Gallon | Diameter | Height |

300L Fermentation Tank | 79US Gallon | 860mm | 2000mm |

500L Fermentation Tank | 132US Gallon | 960mm | 2350mm |

1000L Fermentation Tank | 264US Gallon | 1260mm | 2650mm |

2000L Fermentation Tank | 528US Gallon | 1560mm | 3150mm |

3000L Fermentation Tank | 793US Gallon | 1800mm | 3550mm |

5000L Fermentation Tank | 1321US Gallon | 2000mm | 4450mm |

10000L Fermentation Tank | 2642US Gallon | 2200mm | 6100mm |

20000L Fermentation Tank | 5283US Gallon | 2200mm | 10200mm |

METO fermentation system consist by many fermentation tanks . All tanks are made by SUS304 Stainless Steel, which meet domestic and international food safety and hygiene standards. They are cylindrical cone bottom tank, the cone is 54-72 degree. Their externals are made by 2B stainless steel drawing board ,connected by welding. Their internals have a protective film by pickling passivation, and equipped with 80mm polyurethane insulation. The tanks with dimple plate on cone and side, they are cooled by glycol water or alcohol water. Single tank , single control.

Our Service

1.Pre-sales:

- Layout:Sent us your building floor plan, or the sketch, or tell us the size (length, width, height), we will offer you an

equipment footprint according to your requirement.

- Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

- 3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience.

equipment footprint according to your requirement.

- Technical Drawings : We will offer Technical Drawings of each tank based on the equipment layout .

- 3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience.

2.After-sale

- We can provide weekly production report to let you clear of production progrss and production details;

- We will do equipment test and test report available for you;

- Providing piping connection drawing and English operation manuals;

- Providing equipment installation, debugging, and personnel training service;

- We can help you to arrange transportation till to your location;

- Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetimemaintenance and technical service.

- We will do equipment test and test report available for you;

- Providing piping connection drawing and English operation manuals;

- Providing equipment installation, debugging, and personnel training service;

- We can help you to arrange transportation till to your location;

- Main machine guarantee for three years; Accessories and electronic components will have one year free warranty; Supply lifetimemaintenance and technical service.

Product packaging

FAQ

1.Q:How to calculate the daily output? How many fermenters do I need?

A: Beer production is according to your fermentation process requirements and the number of fermenters configured and we will design the most suitable scheme for you.

2.Q:How long is your delivery time?

A:Usually it takes about 50 working days to manufacture a brewery.Depending on the size of the brewery,the amount of custom designed equipment,our general workload and the way of shipping this period can be shorter or longer.

3.Q:Do you provide after-sales service?

A: Yes,we could provide after-sales service.We have many professional engineers with many years experience, they can go to your place and teach you or your team installation and brewing.

A: Beer production is according to your fermentation process requirements and the number of fermenters configured and we will design the most suitable scheme for you.

2.Q:How long is your delivery time?

A:Usually it takes about 50 working days to manufacture a brewery.Depending on the size of the brewery,the amount of custom designed equipment,our general workload and the way of shipping this period can be shorter or longer.

3.Q:Do you provide after-sales service?

A: Yes,we could provide after-sales service.We have many professional engineers with many years experience, they can go to your place and teach you or your team installation and brewing.

Contact Us