Plastic Injection Mold Maker for Plastic Injection Moulded Parts Production

US $0.35-0.50 / unit

500 unit(s)Minimum order

Place of Origin:

Guangdong China

Brand Name:

Rilong

Model Number:

OEM/ODM

Shaping Mode:

Plastic Injection Mould

Product Material:

PC, PC+ABS,ABS, PP, PVC,POM, TPE, PEEK, TPU etc

Product:

Injection Molded Product

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Place of Origin | Guangdong China |

|---|---|

| Brand Name | Rilong |

| Model Number | OEM/ODM |

| Shaping Mode | Plastic Injection Mould |

| Product Material | PC, PC+ABS,ABS, PP, PVC,POM, TPE, PEEK, TPU etc |

| Product | Injection Molded Product |

| Mould Steel | P20/NAK80/S136/H13/718H... |

| Mould Lifetime | 50k-1000k shots |

| Surface Treatment | Texture/Sand/MT/YS/SPI |

| High Precision | +/-0.01mm |

| Runner | Hot runner and cold runner |

| Cavity | Single or multi Cavity |

| Certification | ISO9001, ISO14001, IATF16949 |

| Color | Pantone/RAL color code/Actual sample color |

| Mould base | LKM HASCO |

| Surface Finishing | Printing/Painting/Laser etching |

Product Detail

OEM Injection Moulding Service Overview

Since 1990, We specialize in providing high-quality injection moulding services to meet various customer needs. Our services cover the entire process from design to production, ensuring each mould meets the highest standards.

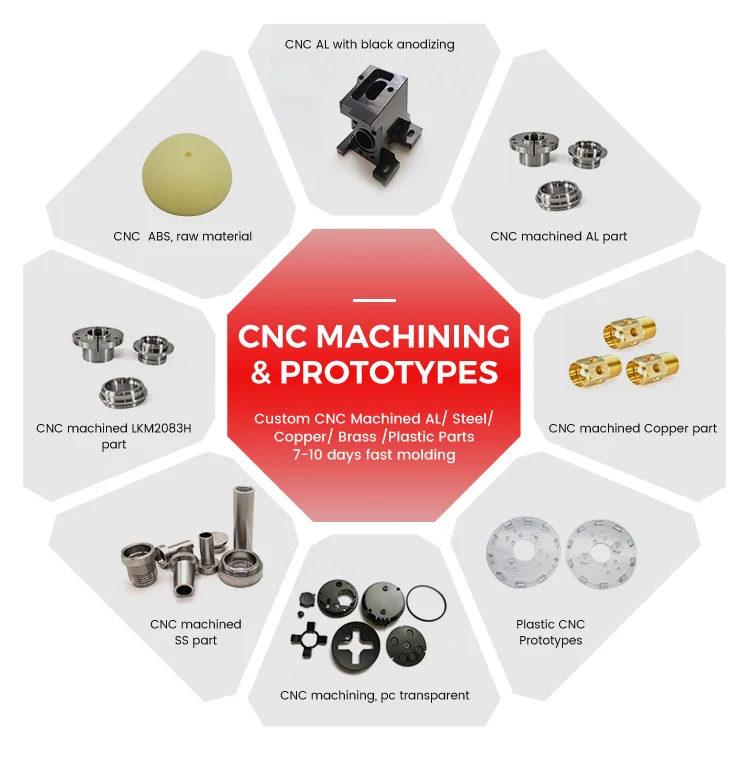

Core Advantage | 30+ years of experience on mold designing, CNC machining and compression&injection molding |

Molding Material | ABS, PC, PA6, PA66, PC+ABS, POM, PA6+10GF, Nylon, PE, PVC, PE, PVC, TPE, TPU, TPV, PET, PEI, LCP, PS, POM, ASA, HDPE, PEEK, PPS, PPA, PBT, PMMA, PPSU, PSU, silicone and rubber etc. |

Product Finishing | Silkscreen, Hand oil coating, Laser etching, Spraying, Glossy coating, Matte Coating, UV Painting, Pad printing, Chrome Plating, Nickle Plating, Non-conductive, Vacuum Metallization, EMV coating and etc. |

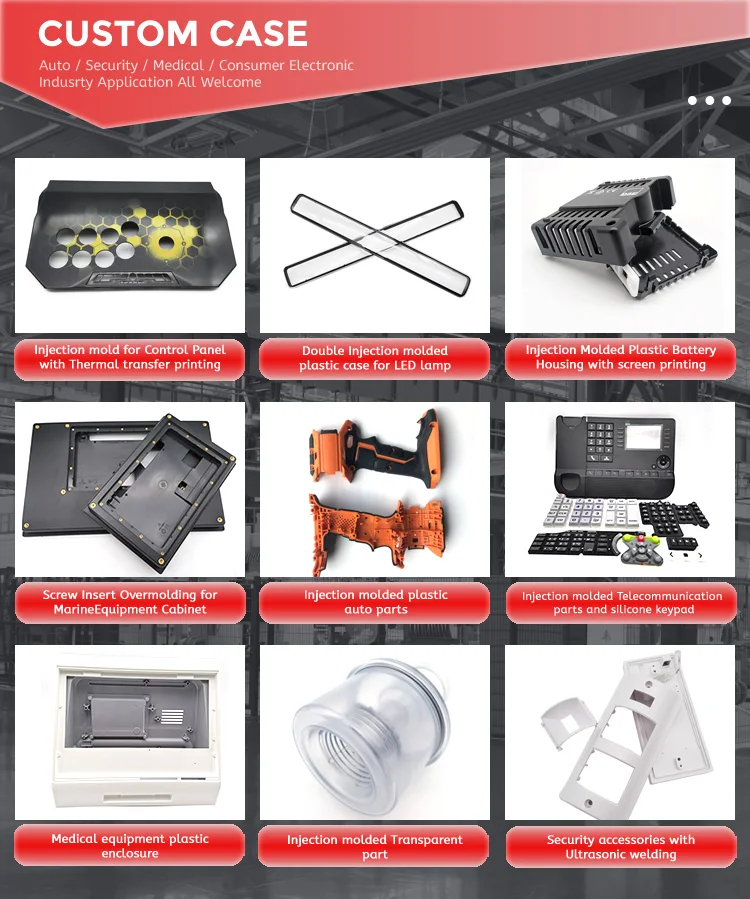

Product Application | Automotive, Medical, Security , Consumer Electronic , Industrial product, Toy etc products |

Mold Standard | DME, HASCO,China domestic |

Runner System | Hot runner and cold runner, YUDO hot runner |

Mold Lifecycle | 50k-1000k shots |

Mould Finishing | Normal Polishing (SPI B1-B3), High Polishing (SPI A1-A3), VDI Texturing, YS1281 Texturing, EDM, Sandblasting Grinding |

Inquiry Information | 2D:dwg,dxf,edrw 3D:step,lgs,X-T,Prt,Sldprt Physical Samples or the size of the multi-angle pictures |

Advanced Tool Equipments | ◆ 8 Advanced CNC machines: Charmilles, Seiki, MITSUBISHI ◆ 4 Advanced EDM : CHARMILLES, SODICK ◆ 2 Advanced WEDM: CHARMILLES,SODICK |

Inspection Standard | FAI (First Article Inspection), Dimension Report,Outgoing products inspection report |

Why Choose Us:

* Expert Advice: We provide guidance to ensure your product design meet final production requirements, considering special materials and design factors.

* Efficiency: Streamline your manufacturing process with our comprehensive services, ensuring a smooth transition from 3D printing to mold manufacturing.

* Complete Production Chain: From mold design to assembly, we offer a centralized and scaled production base to enhance efficiency and reduce costs.

* Efficiency: Streamline your manufacturing process with our comprehensive services, ensuring a smooth transition from 3D printing to mold manufacturing.

* Complete Production Chain: From mold design to assembly, we offer a centralized and scaled production base to enhance efficiency and reduce costs.

State-of-the-Art Production Facilities

Our comprehensive in-house production capabilities include:

* CNC Machining Workshop: Precision machining for high-quality components.

* Tooling Building Workshop: Expert mold design and manufacturing.

* Plastic Injection Molding Workshop: Advanced injection molding for various plastic products.

* Rubber Molding Workshop: Specialized in both liquid and solid silicone rubber molding.

* Secondary Process Workshop: Surface treatments, painting, and printing.

* OEM Assembly Line: Efficient and scalable assembly for custom products.

* CNC Machining Workshop: Precision machining for high-quality components.

* Tooling Building Workshop: Expert mold design and manufacturing.

* Plastic Injection Molding Workshop: Advanced injection molding for various plastic products.

* Rubber Molding Workshop: Specialized in both liquid and solid silicone rubber molding.

* Secondary Process Workshop: Surface treatments, painting, and printing.

* OEM Assembly Line: Efficient and scalable assembly for custom products.

All of material meet with UL, Reach, Rohs certification and world-wide to meet the demand that customer multiple functional requirements.

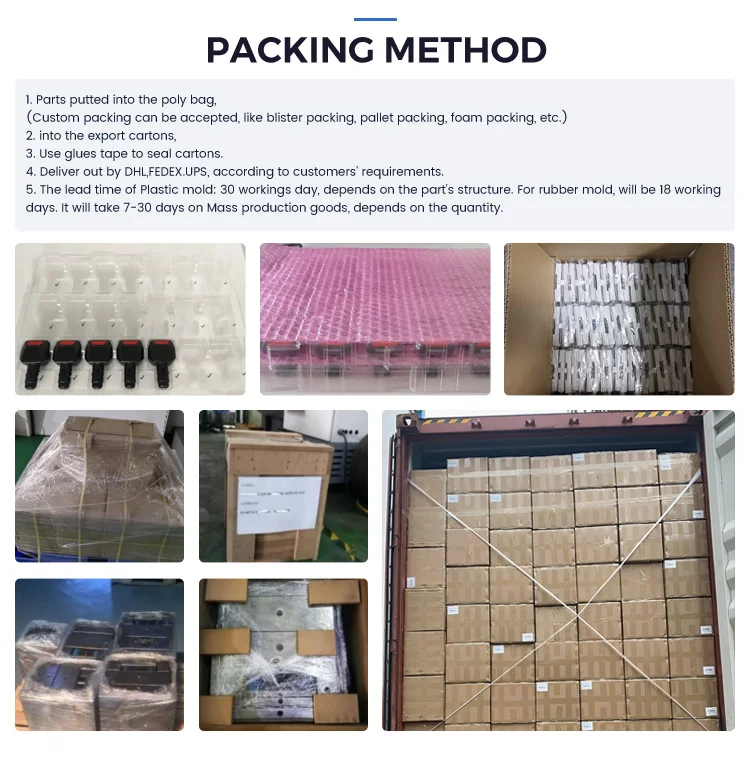

Product packaging

Tailoring the optimal packing method post-completion of the goods;

Crafting bespoke package solutions, including blister packing, artpackage packing, cotton bag packing...

Creating more than 10000 plastic/rubber molds

Exported to the US, Europe and Japan etc.

500+ Cooperated Companies

Professional, reliable, and trustworthy

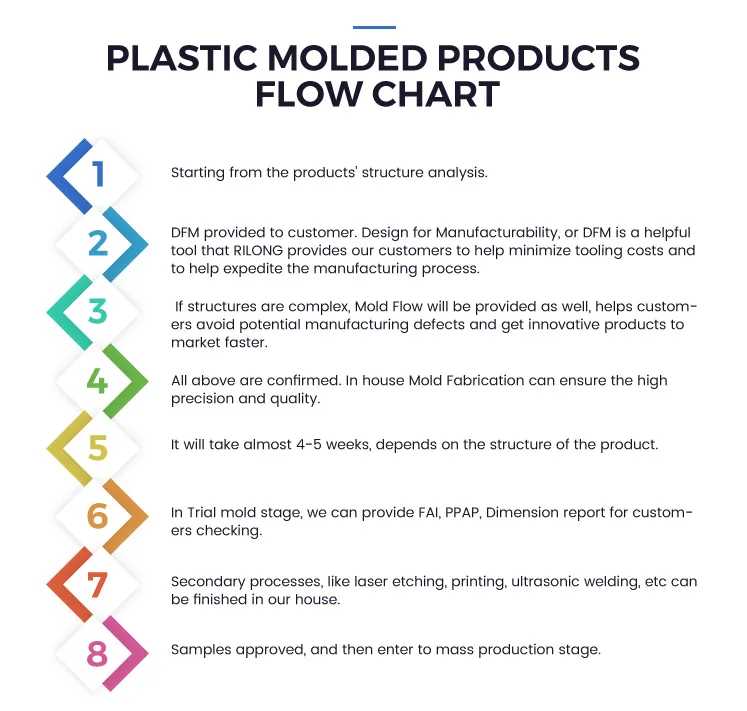

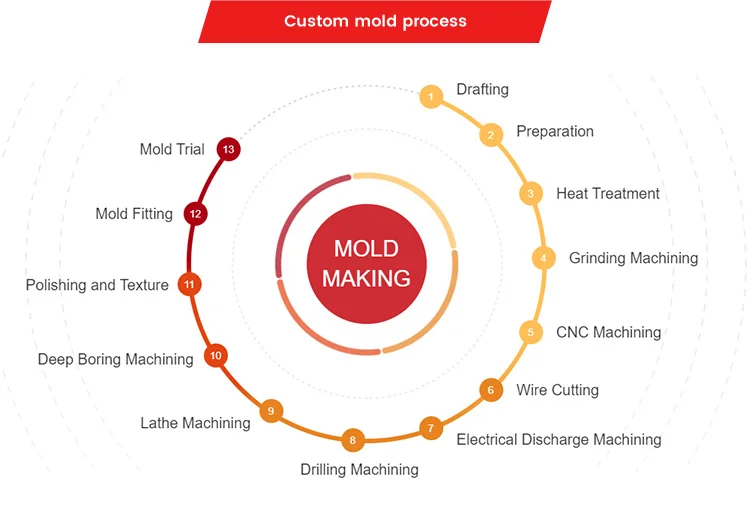

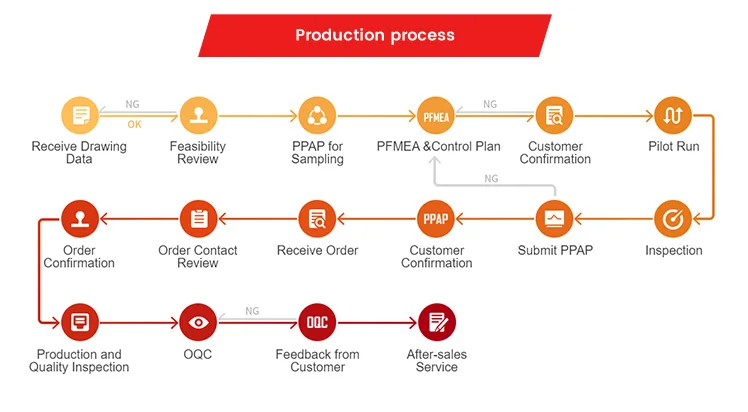

Work Flow Chart

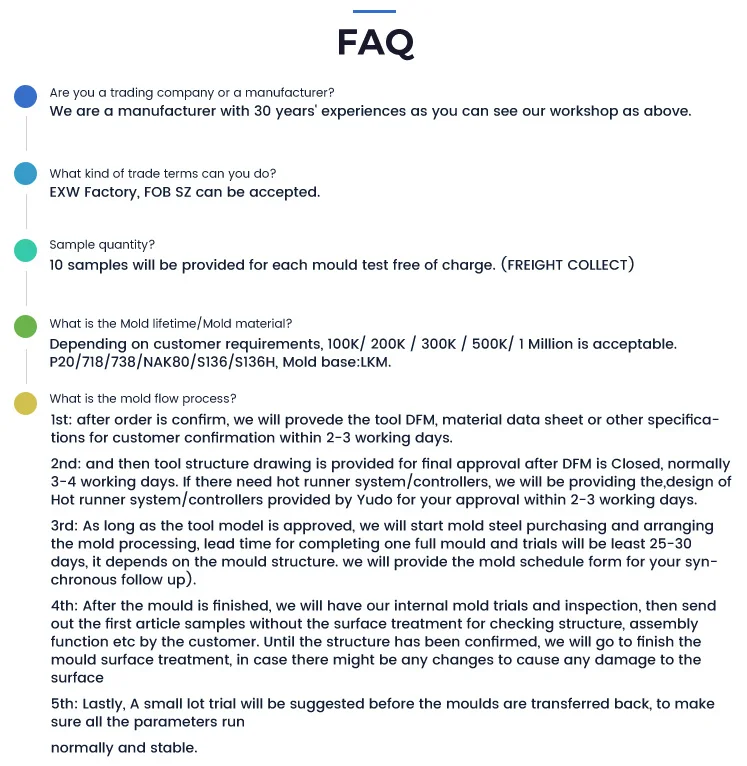

FAQ