Polyacetal POM Price Per kg Fm090 Plastic Resina Acetal Recycle Black Color Recycle Pom-c White POM Material for Injection

1 kilogram(s)Minimum order

color:

as required

Shape:

granules

Application:

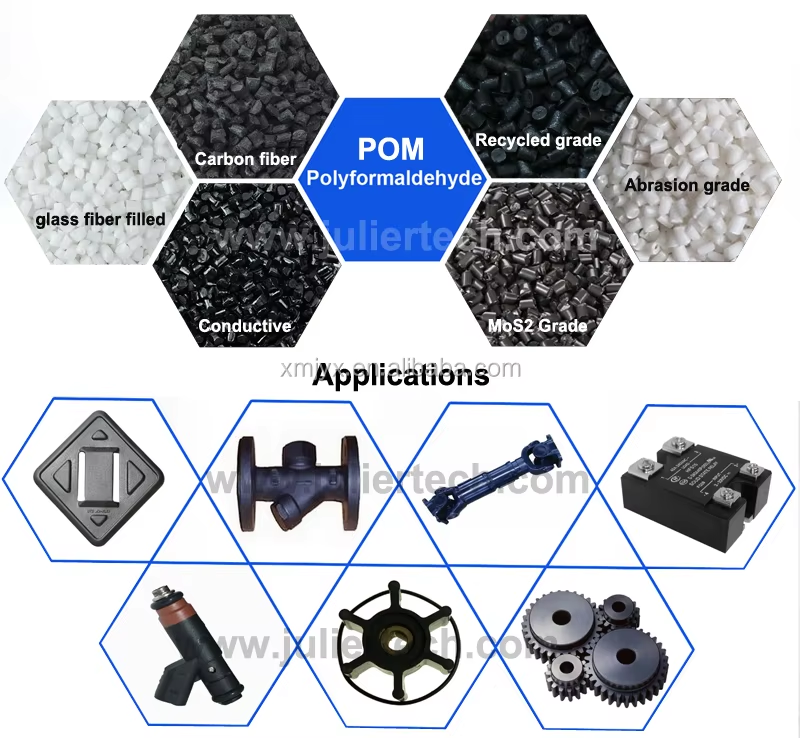

electronic and electrical components, filling grade, automotive parts, General grade, home appliance components, Electrical Components

Grade:

molding, extrusion grade, injection molding grade

Feature:

aging resistance, ANTISTATIC, reinforced grade, toughened grade, standard grade, high temperature resistance, weather resistance, wear resistance, conductive grade, UV resistance, High impact resistance

Place of Origin:

Fujian, China

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| color | as required |

|---|---|

| Shape | granules |

| Application | electronic and electrical components, filling grade, automotive parts, General grade, home appliance components, Electrical Components |

| Grade | molding, extrusion grade, injection molding grade |

| Feature | aging resistance, ANTISTATIC, reinforced grade, toughened grade, standard grade, high temperature resistance, weather resistance, wear resistance, conductive grade, UV resistance, High impact resistance |

| Place of Origin | Fujian, China |

| Brand Name | Julier |

| Product Name | pom pellets |

| Color | Customized Color |

| Type | Granules Pellets Particle Chips |

| Raw material | pom |

| MOQ | Small Orders Accepted |

| Quality | Premium |

| Process | extrusion injection |

| Advantage | made as customized |

| Package | 25 KG Bag |

Product Detail

Product Description

Specification

Grade | Filling Specification | Flame Retardant Grade | Application Range |

Glass Fiber Reinforced Grade | 15% | HB | Suitable for all kinds of mechanical parts. |

25% | HB | ||

Abrasion Resistant Grade | 5% | HB | Suitable for high abrasion resistant grade |

Flame Retardant Grade | 10% | HB | Suitable for fire protection equipment, small appliance accessories and other parts that require self-extinguishment. |

15% | HB | ||

20% | HB | ||

Abrasion Resistant Reinforced Grade | 15% | HB | Suitable for high strength and high abrasion resistant parts. |

15% | HB | ||

Abrasion Resistant Reinforced Grade | 15% | HB | Suitable for low wear products. |

15% | HB | ||

30% | HB | ||

30% | HB | ||

30% | HB | Suitable for low wear and high strength products. | |

30% | HB | ||

Carbon Fiber Reinforced Grade | 10% | HB | Suitable for high strength parts |

20% | HB | Suitable for good conductive and high strength parts | |

30% | HB | ||

40% | HB | ||

MOS2 Filling Grade | 2% | HB | Suitable for thin-walled injection molded parts with high surface requirements, mechanical sliding parts with high self-Lubricating requirements and low warpage products, etc. |

5% | HB | ||

Carbon Fiber Reinforced Grade | 9% | HB | Suitable for anti-static and high-strength parts. |

Conductive Grade | 5% | HB | Suitable for anti-static and good mechanical transmission parts. |

10% | HB | ||

15% | HB | ||

20% | HB | ||

Organic Filling Reinforced Grade | 10% | HB | Suitable for high impact graphic design making, low warpage products, etc. |

Conductive Grade | 15% | HB | Suitable for anti-static and conductive electronic products. |

20% | HB | ||

25% | HB | ||

30% | HB | ||

Stainless Steel Fiber Reinforced Grade | 5% | HB | Suitable for shielding engineering accessories. |

10% | HB | ||

15% | HB | ||

20% | HB |

POM plastic pellets Characteristics

(2) It has excellent properties such as fatigue resistance, creep resistance, wear resistance, heat resistance, and impact resistance. and has a low friction coefficient and good self-lubricating properties.

(1) POM is a crystalline plastic with a density of 1.42g/cm3, with good rigidity.

(2) It has excellent properties such as fatigue resistance, creep resistance, wear resistance, heat resistance, and impact resistance. and has a low friction coefficient and good self-lubricating properties.

(3) POM is not easily hygroscopic, with a water absorption rate of 0.22-0.25%. It has good dimensional stability in humid

environments, with a shrinkage rate of 2.1% (relatively large),with a thermal deformation temperature of 172 ℃.

Mechanical Property

POM has high strength, rigidity, good elasticity, and good wear resistance. Its mechanical properties are excellent, with a

specific strength of up to 50.5MPa and a specific stiffness of up to 2650MPa, which is very close to metals.

environments, with a shrinkage rate of 2.1% (relatively large),with a thermal deformation temperature of 172 ℃.

Mechanical Property

POM has high strength, rigidity, good elasticity, and good wear resistance. Its mechanical properties are excellent, with a

specific strength of up to 50.5MPa and a specific stiffness of up to 2650MPa, which is very close to metals.

Company Profile

Application

It can replace most non-ferrous metals, automobiles, machine tools, instrument internals, bearings, fasteners, gears, spring plates, pipelines, conveyor belt accessories, electric water boilers, pump casings, drains, faucets, etc

Company Profile

Julier (Xiamen) Technology Co Ltd. was founded in 2013. Our company is located in the beautiful city-Xiamen with reputation of sea garden. Our company is mainly engaged in research and development, production and sales of engineering plastics. Our company has strong and professional technical team and efficient management operation system and is equipped with advanced manufacturing equipment.

Our products include PA6, PA66, PP, PBT, PC, PMMA, ABS, POM, TPU, TPE, PA12, PPO, PPS, PEI, etc, are widely recognized

and trusted by users, and can meet continuously changing economic and social needs.There are about 80 employees in our company, the majority of whom is professional production team and experienced technicians. We are confident that our manufacture capacity and service can bring benefits to our esteemed customers.

and trusted by users, and can meet continuously changing economic and social needs.There are about 80 employees in our company, the majority of whom is professional production team and experienced technicians. We are confident that our manufacture capacity and service can bring benefits to our esteemed customers.

We are looking forward to building long-term and cooperative relationships with you.

In order to provide better serve to meet different needs of customers, all projects can be customized according to your requirement, in addition, we try to solve all the problems you may meet, from product design, mold development, material customized, injection molding, and others of the whole area. It comes to be truly one-stop service, save your time, save your costs, put your risk down to zero.

Certificates

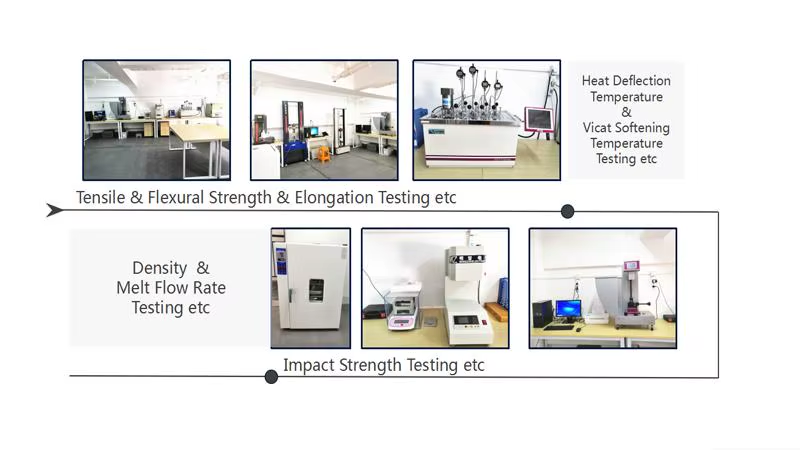

Test Equipments

Packing and Delivery

Our Clients

FAQ

Q: How many years have you been involved in this industry?

Q: Can I buy samples?

A: Since 2013.

Q:Are you a manufacturer, trading company or a third party?

A:We are a manufacturer with premium products and most competitive price.

Q: How can I get the price?

A:We are a manufacturer with premium products and most competitive price.

Q: How can I get the price?

A: Please kindly let us know your requirement of the products, including hardness, color, application of the products, and we will calculate the price within 24 hours.

Q: Can I buy samples?

A:Yes. Please let us know the detailed requirements and we will manufacture in terms of your requirements.

Q:What is the average delivery time?

Q:What is the average delivery time?

A:Sample usually takes about 10-20 days. Bulk order usually takes about 35 days.The specific time will be renegotiated.

Q:How about color?

A:As required by the customers.

Q: What is the quality of your products?

A: All the products must be tested strictly before shipment.

Q: About Material

A:We can customize the material performance according to customers’ requirements.

Q: About Process Method

A: Injection Molding, Profile extrusion, compression molding methods.

Q: About Payment Term

A:It’s flexible, TT, L/C at sight, PAYPAL, BANK, Alibaba’s Trade Assurance, etc.

A:It’s flexible, TT, L/C at sight, PAYPAL, BANK, Alibaba’s Trade Assurance, etc.