Portable Flat Ring Die Machine Line Production Wood Sawdust Stalk Pellet Making Plant on Sales

US $1,900.00-1,980.00 / set

1 set(s)Minimum order

place of origin:

Henan, China

Raw Material:

Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks

pellet diameter (mm):

6 - 12

output (kg/h):

800 - 1000 kg/h

brand name:

LEABON pellet making machines

voltage:

three Phases, 380V/50HZ

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Henan, China |

|---|---|

| Raw Material | Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks |

| pellet diameter (mm) | 6 - 12 |

| output (kg/h) | 800 - 1000 kg/h |

| brand name | LEABON pellet making machines |

| voltage | three Phases, 380V/50HZ |

| dimension(l*w*h) | 1.4*0.75*1.55m PELLET MAKER |

| motor power (kw) | 24 |

| warranty | 1 Year |

| key selling points | Easy to Operate |

| weight (kg) | 3000 |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor |

| Product name | Wood Pellet Machine Production Line Mobile Biomass Straw Pellet Plant |

| Capacity | 800-1000 |

| Pellet size | 6mm-12mm |

| Item | wood crusher/dryer/pellet maker/packing machine,etc. |

| Brand | LEABON |

| Moisture | 8%~12% |

| Keywords | Wood Pellet Making Line Machines |

| MOQ | 1 set |

| Service | 24 Hours Online |

| Advantage | High Performance |

Product Detail

Product Description

Portable Flat Ring Die Machine Line Production Wood Sawdust Stalk Pellet Making Plant on Sales

Brief introduction:

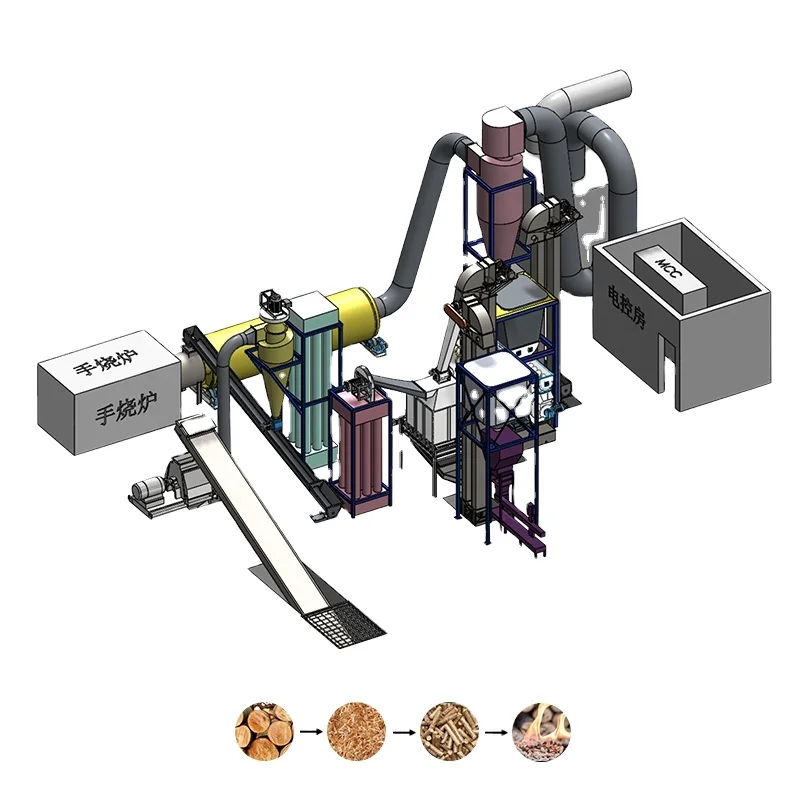

1.LEABON completely pellet production line is designed by ourselves,it includes wood crusher,dryer,conveyor,wood pellet mill,cooler and packing machine, etc. machines.

2. All machines will be controlled by electric cabinet under working condition

3. The whole line needs 5-7 workers to operate.

Flat die wood pellet making line

Ring die wood pellet making line

Main Data

Different step needs different machine

No. | Machine | Steps | Remark |

1 | Raw material | Large size,high moisture content | |

2 | Wood crusher | Crushing step | Crush the raw material from large size to small |

3 | Wood dryer | Drying step | Drying raw materials to reduce moisture |

4 | Pellet making machine | Pellet making step | Making wood pellet Ring die/Flat die---2 types pellet mill |

5 | Cooler&Screener | Pellet cooling&screening step | Cooling pellet temperature. Screening defective particles |

6 | Packing machine | Pellet packing step | 5-25kgs/bag |

7 | Electric box | Control the production line |

Spare parts

Wood crusher:

Used to crush wood log,etc to powder/dust

Wood dryer

Drying materials to reduce moisture that suitable for making wood pellet

Pipe dryer

Drum dryer

Pellet maker

Making pellet from wood log, straw, etc.after crush.

Flat die wood pellet mill.

Ring die wood pellet mill.

Raw material&Final wood pellet

Cooling & screening and Packaging

Used to cool ans screen the the hot wood pellets and pack the wood pellets into bags,convent to stock,delivery and sales

Raw material

Note:

Size of raw materials: 3-5mm; Moisture content of materials: 10-12%.

Final pellets.

Diameter of wood pellets: 6mm,8mm,10mm. Length of wood pellets: 33mm (20-50mm adjustable).

Making line design

Scheme design drawing

Customer production line

Packing & Delivery

Company profile

Related Equipments