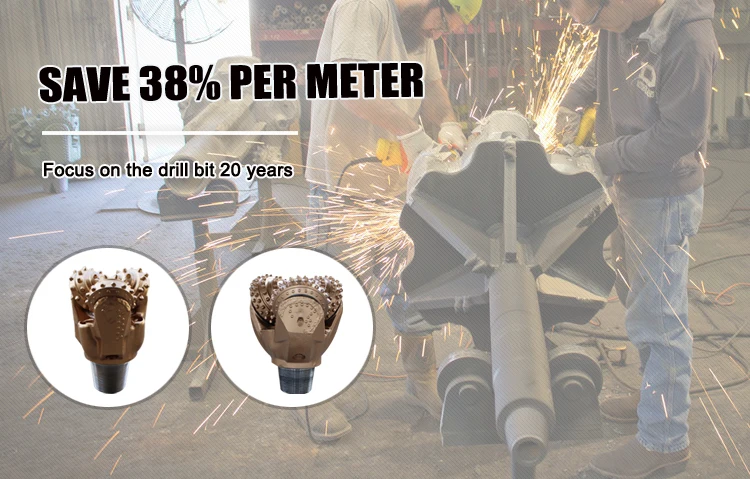

Rock Roller Cone 17 1/2 Inch Mill Tooth Tricone Bits for Well Drilling

US $5,000.00 / piece

1 piece(s)Minimum order

Warranty:

1 Year, 4 Years

Weight (KG):

255

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Place of Origin:

Hebei, China

Brand Name:

ranking

Privacy Policy:

Samples are free within a certain price range

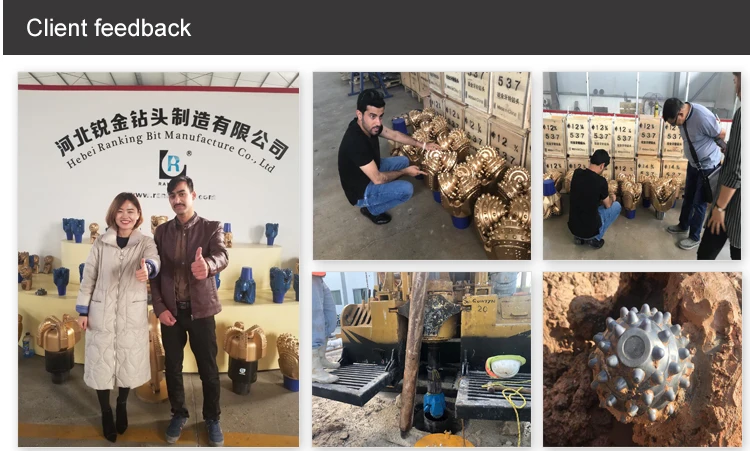

Other recommendations for your business

Contact us

Quik Detail

| Warranty | 1 Year, 4 Years |

|---|---|

| Weight (KG) | 255 |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Place of Origin | Hebei, China |

| Brand Name | ranking |

| Type | DRILL BIT |

| Machine Type | Drilling Tool |

| Material | High Manganese Steel |

| Processing Type | Forging |

| Use | Well Drilling |

| Item name | 17 1/2 inch mill tooth tricone bits for well drilling |

| Size | 17 1/2" |

| IADC Codes | IADC235 |

| formation | Soft formation |

| Application | well drilling,oil drilling,gas drilling etc. |

| API REGULAR PIN | 7 5/8 |

| Make up Torque | 46.1-54.2 |

| Color | Red Blue Yellow Green |

| shipping item | by sea or by air |

Product Detail

Hot Sale

Product Description

Bit Size | 17 1/2" |

IADC Code | 235 |

Nozzle Qty/Type | 3NZ |

Connection | 7 5/8 inch API Reg |

Making up Torque(KN.m) | 16.3-21.7 |

Rotary Speed(rpm) | 40-110 |

Weigth on Bit(KN) | 35-105 |

Max.WOB(KN) | 120 |

Flow Rate(lps) | 18-27 |

Why Choose Us

Cutting Structure

The wear-resistance of the teeth is enhanced with premium tungsten carbide hardfacing on the tooth surfaces for the steel tooth bit.

The durability of permium tungsten carbide inserts is improved with new formulas and new techniques for insert bit.

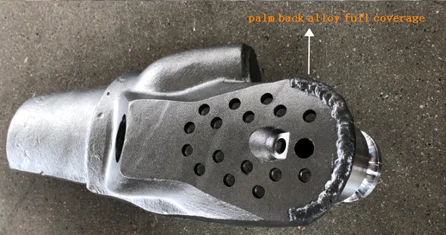

Palm back alloy full coverage

Multipe gauge protection with gauge trimmers on the heel of cone,tungsten carbide insert and hardfacing on the shirttail increases gauge holding capability and bearing life.

Hard alloy nozzle

Can control the flow of water, reduce the heat in the process of the bit, increase the service life of the bit

Screw thread

The upper part of the drill bit is provided with a thread for connecting with the drill string.

According to your requirements, we can modify the screw and also provide the corresponding conversion connector

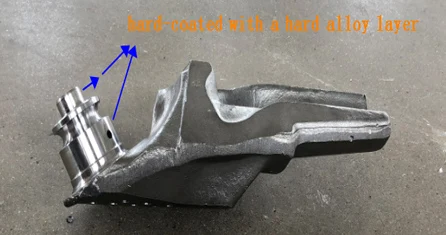

Hard-coated with a hard alloy layer

This can reduce the bearing wear and greatly improve the service life of the bit

Silver-plated

This reduces wear and tear and improves the use of the drill bit compared to traditional processes

Professional welding technology

According to the vulnerable point of the bit, we have professional welding personnel to focus on the protection, to provide alayer of protective film for the bit

FAQ

Q1. Whether accept customized according to customers' requirements ?

A: Yes, We accept customized, no matter how much is thepurchase quantity

Q2. Can I expect a quality products?

A: Yes. All our activities are accredited to ISO 9001:2008 and API, both inproducts and services, at the same time, mature production technology ensuring the quality satisfy international request.

Q3.About lead time and shipping time?

A: The lead time depend on quantity of order. Usually shipped by sea, small order or urgentorder we can send you by air after received your agreement. According the distance from china to your port, usually from China toEuropean about 25 days. To West of American 20 days.

Q4. What is your trade terms?

A: We offer EXW, FOB, CFR, CIF, DDU.

Q5. Whatis your payment terms and method?

A: Our payment terms: normally 30% deposit, balance 70% before shipment. Our payment method, weaccept T/T, L/C.