Rotor Powder Separator / Gravity Separator for Powder / Centrifugal Separator for Fine Powder

US $10,000.00-27,200.00 / set

1 set(s)Minimum order

Type:

Magnetic Separator

Production Capacity:

Actual Demand

Place of Origin:

Shanghai, China

Brand Name:

YINGYONG

Voltage:

Customized

Dimension(L*W*H):

Actual Demand

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Type | Magnetic Separator |

|---|---|

| Production Capacity | Actual Demand |

| Place of Origin | Shanghai, China |

| Brand Name | YINGYONG |

| Voltage | Customized |

| Dimension(L*W*H) | Actual Demand |

| Weight | 5000 KG |

| Warranty | 1 Year |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | Bearing, motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox |

| Key Selling Points | High-accuracy |

| Product name | Rotor powder separator |

| Spindle speed(r/min) | 120-1250 |

| Equipment load(t) | 5.5-44.5 |

| Color | Customized Making |

| Feature | High Recovery Rate Easy |

| Usage | Mining |

| Quality | High Reputation |

| After sale service | Video Technical Support |

| Advantage | High Separation Efficiency |

| Price | Negotible |

| Applicable Industries | Manufacturing Plant, Energy & Mining |

| Showroom Location | None |

| Condition | New |

| Warranty of core components | 1 Year |

| Marketing Type | New Product |

Product Detail

Product Description

Rotor powder separator

The YDZ series highly effective rotor classifier is the new classifier machine design by self which our company combined the foreign advanced separator techniques, aimed at the different properties of the cement and the cement raw material, based on the rotor classifier. The practice shows that the device can achieve efficiency choose 85%, flexible adjustment and fineness, stable

and reliable performance.

and reliable performance.

Working principle

The material falls from the mill through the top hopper of the classifier into the combined propeller-type scattering plate,which is integrated with the rotor. At the high speed of the scattering plate, the material flies around under the effect of centrifugal force, and the pressure of the material causes the updraft of the propeller scattering plate blade to rise, thereby forming the material boiling. Fine forces float upward in a dispersed state of flight, while thicker or heavier fragments are scattered by the plates falling along the inside. Make your first choice.

There is a squirrel-cage rotor on top of the 2.1.2 board. In the powder selection chamber, near the flat surface of the top rotor, the airflow and the materials scattered in the airflow rotate with the flatness circle. High speed, forming a strong uniform vortex near the gradient circle. The centrifugal force of the material in the air flow is adjusted by the speed of the main shaft of the stepless motor. As the speed increases, the force also increases. Then if the operating air is maintained, the cut size will be reduced and the finished product will be small; if the speed is reduced, the product will be thickened. Therefore, in the process of processing products, fineness is required for flexible adjustment and control, and the effect of particle classification is improved, and the efficiency of powder selection is improved.

After the squirrel-cage rotor is classified, the fine grain circulating wind is brought to the outside with various cyclones. As a result of the new cyclone duster design with two exit structures, and a cone-shaped reflector screen in the ventilated Menorca snail horn, a decelerator plate was added to the bottom of the cyclone cylinder liner, thus making the cyclone dust collector The fluid resistance is greatly reduced. The wind is guided to enter the cyclone at high speed collector. The wind in the enlarged part of the snail's horn suddenly drops, which accelerates the particle sedimentation and also

improves the dust collection efficiency of the cyclone dust collector. Under the action of wind, it directly enters the high-efficiency dust collector from the air outlet, which greatly reduces the dust content in the circulating wind and reduces the final fineness.

After the squirrel-cage rotor is classified, the fine grain circulating wind is brought to the outside with various cyclones. As a result of the new cyclone duster design with two exit structures, and a cone-shaped reflector screen in the ventilated Menorca snail horn, a decelerator plate was added to the bottom of the cyclone cylinder liner, thus making the cyclone dust collector The fluid resistance is greatly reduced. The wind is guided to enter the cyclone at high speed collector. The wind in the enlarged part of the snail's horn suddenly drops, which accelerates the particle sedimentation and also

improves the dust collection efficiency of the cyclone dust collector. Under the action of wind, it directly enters the high-efficiency dust collector from the air outlet, which greatly reduces the dust content in the circulating wind and reduces the final fineness.

Basic structure

The main part of YDZ series high-efficiency rotor classifier consists of housing, squirrel-cage rotor, maintenance door, cyclone tube, fan, motor, motor bracket, non-standard pipelines, legs and so on. The cabinet is all welded, and the door rubber is used for maintenance. Make sure there is no wind in the room.

Structure characteristics

Compared with traditional classifiers, YDZ series double rotor classifiers have the following special advantages:

1. The combined detachable propeller diffuser is used to make the material rise quickly and form a uniform curtain, which is the first choice.

2. Detachable wear-resistant 40Cr hot-rolled instead of seamless steel pipe, which solves the problem that when the steel pipe is worn, the material enters the inner steel pipe through the perforation position, which breaks the balance, causes vibration, and extends the service life of the cage.

3. Optimized cage angle, column mesh density and speed design to make it more suitable for material selection powder.

4. With reference to the international advanced cyclone dust collector technology, combined with material properties, aiming at the snail horn of the cyclone dust collector, the computer simulation design achieves high and low aspect ratios, reduces fluid resistance, and improves collection efficiency.

5. Using stepless speed regulation motor, fine adjustment, sensitive and reliable adjustment, wide adjustment range.

6. In all easy-to-grind sites, new wear-resistant pads are adopted for protection, which is easy and convenient to maintain and prolong the service life of the main engine.

7. The rotating system adopts advanced centralized grease lubrication system, which successfully solves the problem of oily vulnerability.

8. It adopts balanced structure, which is basically free of vibration. The new fan dust and shock absorption device minimizes system vibration and greatly improves the stability of the equipment operation.

2. Detachable wear-resistant 40Cr hot-rolled instead of seamless steel pipe, which solves the problem that when the steel pipe is worn, the material enters the inner steel pipe through the perforation position, which breaks the balance, causes vibration, and extends the service life of the cage.

3. Optimized cage angle, column mesh density and speed design to make it more suitable for material selection powder.

4. With reference to the international advanced cyclone dust collector technology, combined with material properties, aiming at the snail horn of the cyclone dust collector, the computer simulation design achieves high and low aspect ratios, reduces fluid resistance, and improves collection efficiency.

5. Using stepless speed regulation motor, fine adjustment, sensitive and reliable adjustment, wide adjustment range.

6. In all easy-to-grind sites, new wear-resistant pads are adopted for protection, which is easy and convenient to maintain and prolong the service life of the main engine.

7. The rotating system adopts advanced centralized grease lubrication system, which successfully solves the problem of oily vulnerability.

8. It adopts balanced structure, which is basically free of vibration. The new fan dust and shock absorption device minimizes system vibration and greatly improves the stability of the equipment operation.

Use effect

Compared with traditional classifiers, YDZ series rotor classifiers have the following advantages:

1. Particle size distribution, the particle level is more reasonable, and the particles between 3μm and 30μm are significantly increased, which significantly improves the product quality.

2. Simple and fine operation.

3. Wear parts are designed for wear protection, less maintenance and long service life.

4. Energy saving and consumption reduction, the unit energy consumption of the system is 30% lower than that of the traditional circulating flow system.

5. It can increase the open-flow milling powder by 60-80% and the powder selection efficiency exceeds 85-90%.

6. Easy to install, the fan has a shock-absorbing base, and a steel frame can be used directly.

7. Low investment, convenient operation and maintenance, especially suitable for renovation of old houses.

8. The suction power of the classifier is small and there is no dust leakage, which improves the production environment.

1. Particle size distribution, the particle level is more reasonable, and the particles between 3μm and 30μm are significantly increased, which significantly improves the product quality.

2. Simple and fine operation.

3. Wear parts are designed for wear protection, less maintenance and long service life.

4. Energy saving and consumption reduction, the unit energy consumption of the system is 30% lower than that of the traditional circulating flow system.

5. It can increase the open-flow milling powder by 60-80% and the powder selection efficiency exceeds 85-90%.

6. Easy to install, the fan has a shock-absorbing base, and a steel frame can be used directly.

7. Low investment, convenient operation and maintenance, especially suitable for renovation of old houses.

8. The suction power of the classifier is small and there is no dust leakage, which improves the production environment.

Technical Parameters

model | YDZ300 | YDZ500 | YDZ600 | YDZ700 | YDZ800B | YDZ900B | YDZ1000B | ||

production quantity for one per hour(t/h) | cement | 7-8 | 16-22 | 20-26 | 26-35 | 43-54 | 64-76 | 85-105 | |

raw | 10-12 | 19-28 | 28-35 | 33-46 | 52-65 | 75-95 | 110-130 | ||

products fineness (%) | cement | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 | 2-4 | |

raw | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 | ||

spindle speed(r/min) | 125-250 | 190-380 | 150-350 | 150-350 | 150-350 | 140-350 | 120-300 | ||

Equipment load(t) | 5.5 | 10.5 | 14.5 | 17 | 25.5 | 30 | 44.5 | ||

Production Capacity

Quality Control

Company Profie

Our Business

Custom Visiting

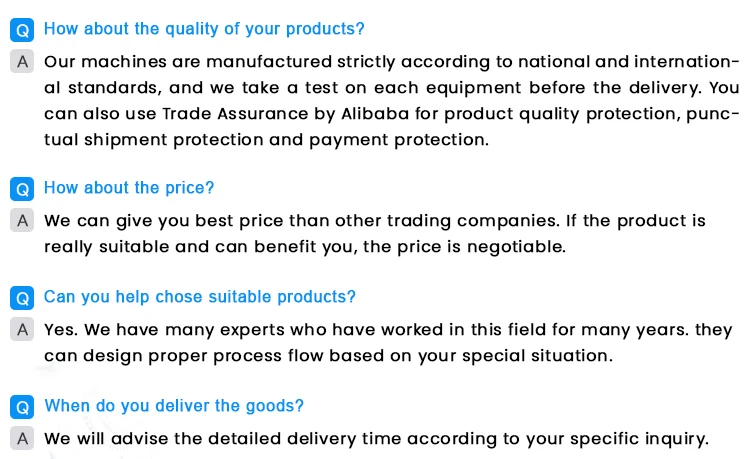

FAQ