SDBALLS Stainless Steel Balls 6mm 8mm 10mm Forged Grinding Balls

US $3.15-3.20 / kilogram

2 kilogram(s)Minimum order

Applicable Industries:

Food & Beverage Factory, Food & Beverage Shops, Energy & Mining, Other

Place of Origin:

Shandong, China

Brand Name:

SDBALLS

Model Number:

stainless steel ball

Material:

stainless steel bead, AISI304 316 420 440 stainless steel

Size:

6mm 8mm 10mm

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Applicable Industries | Food & Beverage Factory, Food & Beverage Shops, Energy & Mining, Other |

|---|---|

| Place of Origin | Shandong, China |

| Brand Name | SDBALLS |

| Model Number | stainless steel ball |

| Material | stainless steel bead, AISI304 316 420 440 stainless steel |

| Size | 6mm 8mm 10mm |

| Name | SS304 stainless steel ball |

| Grade | G10to G1000 |

| Hardness | soft ball |

| surface | High Polished |

| MOQ | 1kg |

| OEM | Customized Diameters |

| Sample | Free |

| Package | Carton box and wooden case |

Product Detail

Product Description

Carbon Steel Ball

AISI1018 Case Hardened

AISI1085 Through Hardened

AISI1065 Throught Hardened

Chrome Steel Ball

AISI 52100

Chrome Steel Through hardened 62-65 Rockwell "C"

Stainless Steel Ball

AISI 302 AISI304 AISI316

AISI 420 AISI440

Flying saucer steel: high quality stainless steel wire,Cold heading of carbon steel wire rod,Polished,Used for rough throwing, Further polishing of parts after polishing,Provide a wide range of light on the part surface,Or to mirror state,Apply to stainless steel, copper, aluminum alloy and other materials of non-ferrous metal parts (such as forging parts, die-casting parts, machining parts and so on).

SIZE: 1/4"x1/4", 3/8"x3/8", 1/16"x1/16"

Material : Carbon Steel Ball

Stainless Steel Ball

Introduction: steel diagonal tumbling media is rust and corrosion resistant and able to stand up to strong compounds. Using a Stainless steel media is important to avoid rust and works great for wet tumbling. The abrasion resistance of Stainless steel

media is 3-5 times greater compared to cast steel media.

media is 3-5 times greater compared to cast steel media.

Silicon Nitride Ceramic Ball

The ultra-precision grinding and polishing technology of Si3N4 ceramic ball mainly

includes magnetohydrodynamic polishing, chemical mechanical polishing and ultrasonic assisted polishing. These new "flexible" machining techniques enable the micro-cutting of Si3N4 ceramic ball surface materials, allowing the excess to be removed by means of plastic fracture to obtain a super-smooth non-damaged surface.

Zirconia offers chemical and corrosion resistance to temperatures well above the melting point of Alumina. In its pure form

crystal structure changes limit mechanical applications, however stabilized Zirconias produced by addition of Calcium, Magnesium or Ytrium Oxides can produce very high strength, hardness and particularly toughness.

Alumina Ball AI2O3

The alumina ball is a high-quality grinding medium made of selected high grade material, advanced molding technology and calcined in high temperature tunnel kiln. Possessed with high density, high hardness, low wear, good seismic stability and good corrosion resistance, the products are the most ideal medium for grinding glaze, blank and mineral powder processing, and are used as the grinding medium of ball mill in ceramics, cement, paint, refractory, inorganic mineral powder and other industries.

Tungsten alloy sheet can be used as counterweights in various fields, such as mechanical hammer, hammers, oil drilling platform counterweights and shock proof tool holder. Also they can be used for the X ray target, collimator, nuclear fuel container, and the needle shielding etc.

Product Usage

Please be noted that the price of steel balls in our website is merely the reference price and the actual one is subject to our final confirmation.

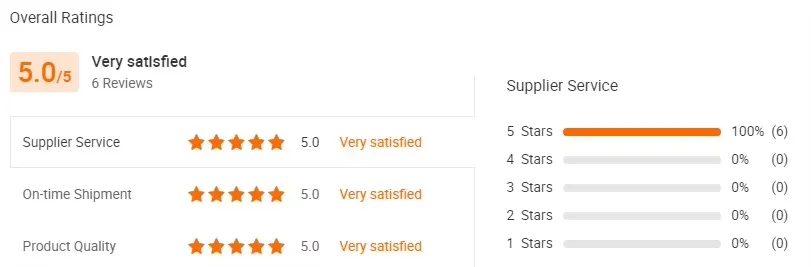

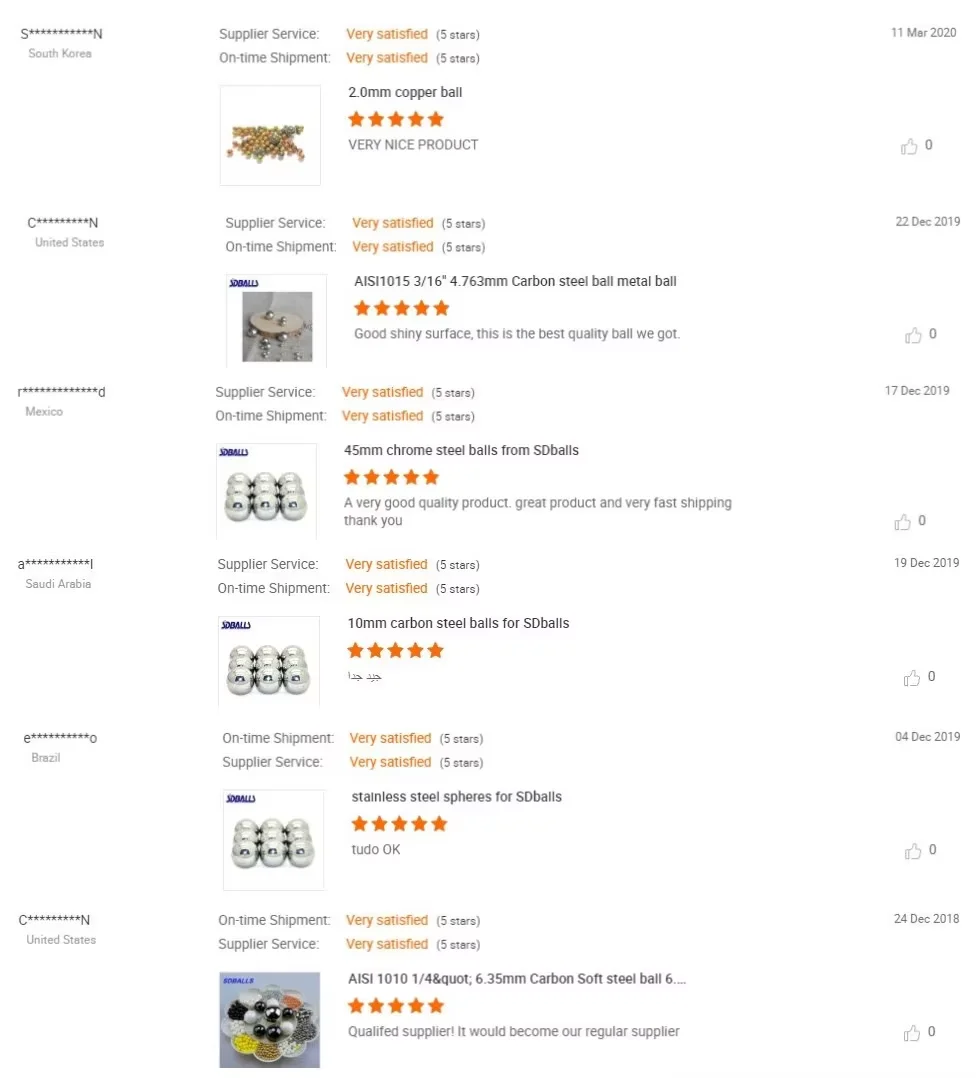

Feedback

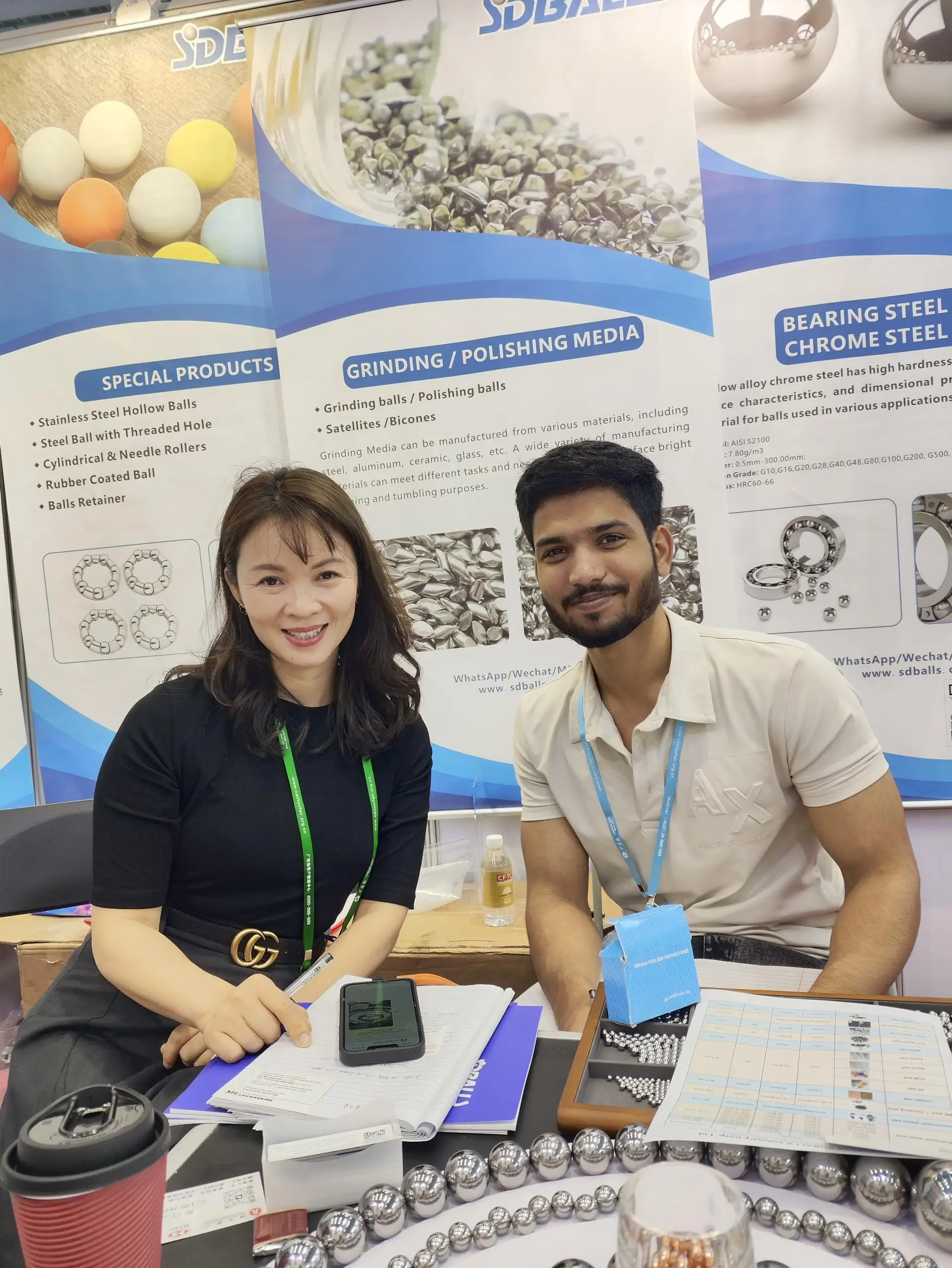

Company Introduction

1. 30 years’ professional steel ball manufacture experience

2. Covers the area of 8000 square meters

3. 200 sets of modern and efficient production equipment

4. Annual production capability of over 5000 tons steel ball

2. Covers the area of 8000 square meters

3. 200 sets of modern and efficient production equipment

4. Annual production capability of over 5000 tons steel ball

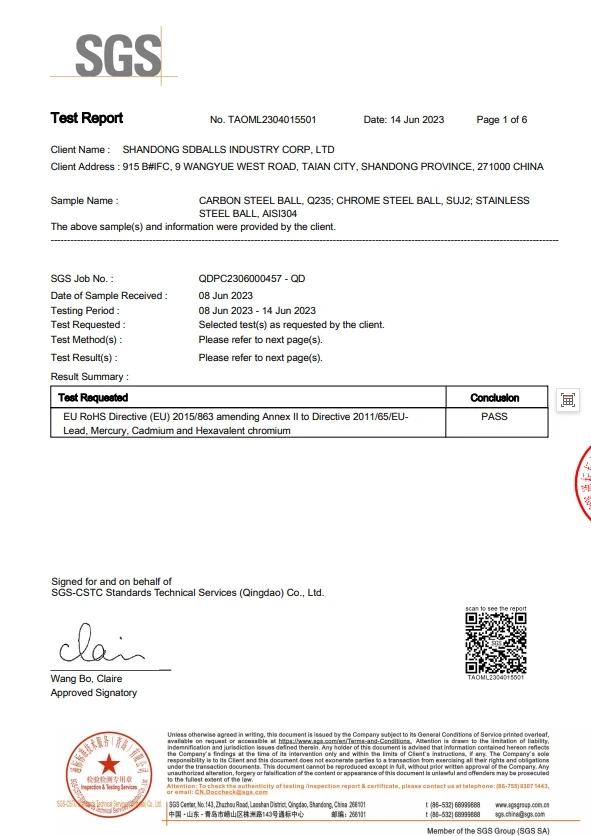

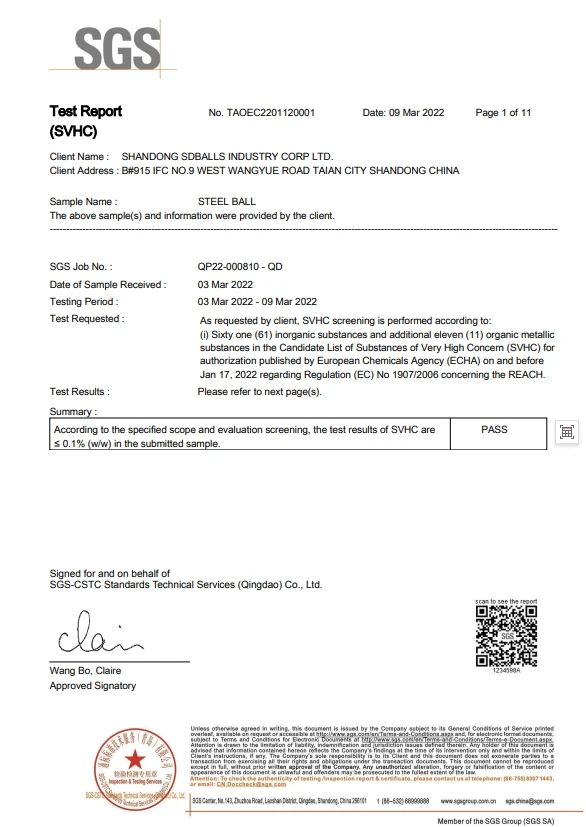

Certifications

We can also provide PFMEA, Control Plan, CQl-9, PPAP, 100PPM and other QC reports. For other special tests andreports required by customers (such as raw material chemical analysis, salt spray testing, ROHS certification, etc.), we can provide samples reported by third party testing institutions.

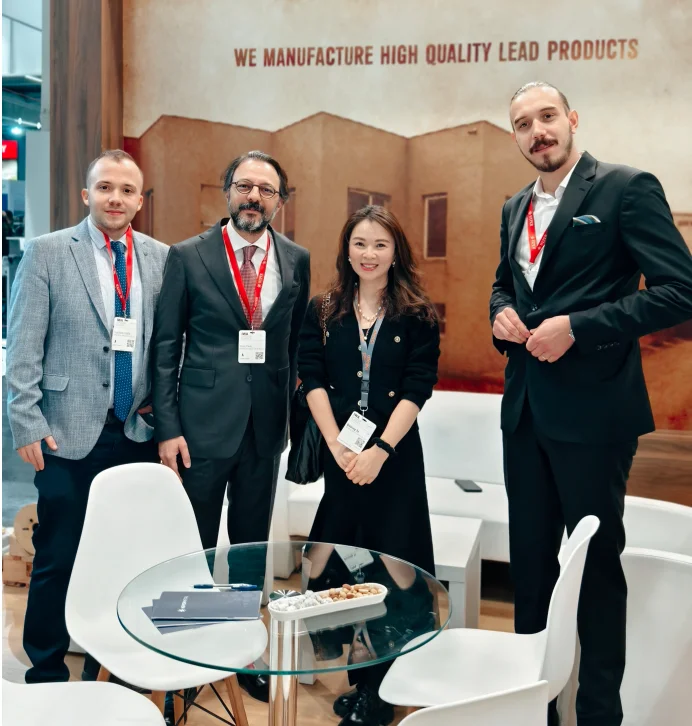

Attend Exhibition

Manufacturing process

Raw Material | The wire rod is drawn to the required size, in closer tolerance so that it can be used in cold forging |

Cold Forging | Calculated length of wire is sheared and cold forged in a close die to give it the spherical shape. |

Flashing | The rolling between plates with concentric grooves in order to eliminate the heading witness marks and to increase the precision of the ball. In this operation the spheres are ground between two concentric pressure plates to correct the spherical shape and remove the seam formed in the cold forging |

Heat Treating | Carbon steel balls are next carburized and hardened . Heat treatment impacts the desired hardness and case depth. |

Descaling | This step removes the residues and by-products for the preceding process. |

Hard Grinding | Here the hardened balls are ground to improve surface finish and geometrical parameters. Several careful grinding processes with ceramic wheels lead to a higher size precision preparing the balls for the next final lapping operation. |

Finishing | Proprietary chemical and mechanical processes give the balls their final micro-smoothed finish, increasing wear resistance and product longevity. |

Inspecting | All products pass through at least two 100% inspection stages, using proprietary, automated inspection processes. |

Inspection & packaging

FAQ