SDDOM HZS25 -HZS120 Small Cement Plant 25m3/h to 120m3/h Ready Mix Mobile Concrete Batch Plant Layout for Sale

US $20,500.00-25,500.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, Gearbox, motor

Power Type:

Electric

Place of Origin:

Shandong, China

Brand Name:

SDDOM

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Gearbox, motor |

| Power Type | Electric |

| Place of Origin | Shandong, China |

| Brand Name | SDDOM |

| Power | 18.5KW |

| Dimension(L*W*H) | Seller's Final Confirmation |

| Weight | 120000 kg |

| Warranty | 12 Months |

| Machine Type | Production line |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Product name | ready mix mobile concrete batch plant layout for sale |

| Keyword | concrete mixing station |

| Type | Fixed Concrete Batching Plant |

| Capacity | 25m3/h-120m3/h concrete batching plant |

| Application | Construction Projects |

| Discharging Height | 3.8m |

| Color | Request |

| Productivity | 25m3/hr to more |

| Model | HZS25 |

Product Detail

SDDOM hot sale HZS25 -HZS240 small cement plant 25m3/h-240m3/h mobile concrete batch plant for sale

Customize service provided

Our engineers team provide customize service according to customers' on site working condition.

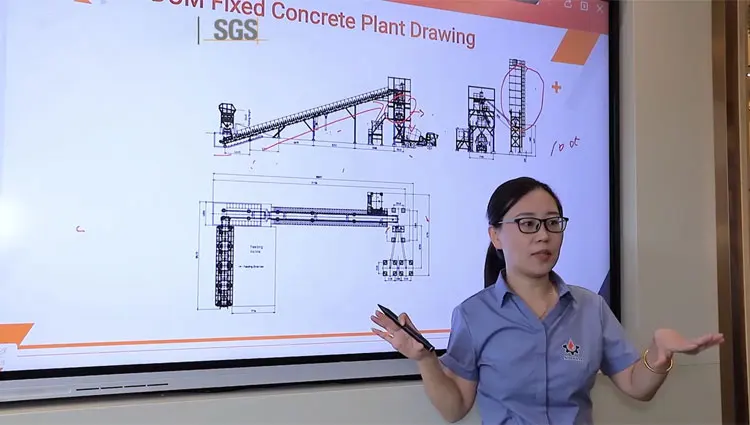

To meet exact request, we have meetings about the design. In the picture, I am sharing customer's idea to our engineers team. Our engineers give drawings to confirm all detailed requirement.

SDDOM Stationary Cement Concrete Batching Plant Mixing Plant Introduction

The stationary concrete batching plant is including 4 types . 1) Fixed Bucket lift type 25 - 75m3 per hour .

2) Free foundation 60 / 75m3 per hour .

3) Fixed belt lift type 60 - 180m3 per hour.

4) Container type 90 - 180m3 per hour.

Other: Dry batching plant 50 - 180m3 per hour.Dry batching plant is without mixer. Mixing material in the mixing truck. The price of cement silo and screw conveyor is not included. It's equipped based on model of batching plant. Please tell us the model you

need,we send complete quotation to you. And the port name that near to you.

Advantages of Cement Silo for Concrete Batching Plant:

For easy transportation and to save the ocean freight, we design the walls of cement silo into pieces. The pieces only take small space and they are very easy to be assembled together at the construction site. It is also very easy for the later repair or replacement of any corrosion.

The stationary concrete batching plant is including 4 types . 1) Fixed Bucket lift type 25 - 75m3 per hour .

2) Free foundation 60 / 75m3 per hour .

3) Fixed belt lift type 60 - 180m3 per hour.

4) Container type 90 - 180m3 per hour.

Other: Dry batching plant 50 - 180m3 per hour.Dry batching plant is without mixer. Mixing material in the mixing truck. The price of cement silo and screw conveyor is not included. It's equipped based on model of batching plant. Please tell us the model you

need,we send complete quotation to you. And the port name that near to you.

Advantages of Cement Silo for Concrete Batching Plant:

For easy transportation and to save the ocean freight, we design the walls of cement silo into pieces. The pieces only take small space and they are very easy to be assembled together at the construction site. It is also very easy for the later repair or replacement of any corrosion.

Basic parameters

Model | HZS25 | HZS35 | HZS50 | HZS60 | HZS75 | HZS90 | HZS120 | HZS150 | HZS180 |

Discharging Capacity (L) | 500 | 750 | 1000 | 1000 | 1500 | 1500 | 2000 | 2500 | 3000 |

Charging Capacity(L) | 800 | 1200 | 1600 | 1600 | 2400 | 2400 | 3200 | 4000 | 4800 |

Maximum Productivity(m³/h) | 25 | 35 | 50 | 60 | 75 | 90 | 120 | 150 | 180 |

Charging Model | Skip Hopper | Skip Hopper | Skip Hopper | belt conveyor | Skip Hopper | belt conveyor | belt conveyor | belt conveyor | belt conveyor |

Standard Discharging Height(m) | 1.5~3.8 | 2~4.2 | 4.2 | 4.2 | 4.2 | 4.2 | 3.8~4.5 | 4.5 | 4.5 |

Number of Species of Aggregate | 2~3 | 2~3 | 3~4 | 3~4 | 3~4 | 4 | 4 | 4 | 4 |

Maximum Aggregate Size(mm) | ≤60mm | ≤80mm | ≤80mm | ≤80mm | ≤80mm | ≤80mm | ≤120mm | ≤150mm | ≤180mm |

Cement/Powder Silo Capacity(set) | 1×100T | 2×100T | 3×100T | 3×100T | 3×100T | 3×100T | 4×100T or 200T | 4×200T | 4×200T |

Mixing Cycle Time(s) | 72 | 60 | 60 | 60 | 60 | 60 | 60 | 30 | 30 |

Total Installed Capacity(kw) | 60 | 78.5 | 111 | 145 | 110 | 198.06 | 210 | 230 | 288 |

Specification

Detail different parts

According different use, the concrete have below choice:

According different use, the concrete have below choice:

High quality Twin shaft concrete mixer

Adopt double spiral belt mixer, stable and reliable, easy to clean (only clean once a month). Its excellent performance and productivity performance can save about 15% mixing time and 20% production energy consumption. The mixer have patent monitoring and alarm system,that can inquiry the mixer running and alarm record.

30 years manufacture planetary Concrete mixer

For higher quality concrete requirements, like the Prefab concrete.Should use planetary mixer.The mixer adopt parallelogram

structure mixing blades,which can be turned 180° for reuse to increase service life.

Mixer adopt hydraulic discharge and can match 2 discharge doors.

structure mixing blades,which can be turned 180° for reuse to increase service life.

Mixer adopt hydraulic discharge and can match 2 discharge doors.

Cumulative weighing batching machine

Suitable for small capacity concrete batching plant.All the aggregate bins use one big weighing hopper. This type is more economical.

Separate weighing batching machine

Suitable for large capacity concrete batching plant.Every aggregate bin use one weighing hopper. This type is more accurate.

Skip hopper aggregate feeding system

Suitable for small capacity concrete batching plant. Skip hopper climb up along its railway.Speed is a little slower than belt

conveyor. Price is lower.

conveyor. Price is lower.

Belt conveyor aggregate feeding system

Suitable for large capacity concrete batching plant. It can convey the aggregate very fast.

With higher productivity.

Product packaging

Applications and Advantages

Company Profile

Shandong DOM Machinery Equipment CO., Limited

is located in Taian, Shandong, China, is one of the major exporters of concrete mixing plants. We have 6 excellent designers, 6 experienced technicians and 2 strict supervisors, one skilled manufacturing team with over 30 people, an energetic sales team with 6 sales person. Our factory is total 8800m2.

is located in Taian, Shandong, China, is one of the major exporters of concrete mixing plants. We have 6 excellent designers, 6 experienced technicians and 2 strict supervisors, one skilled manufacturing team with over 30 people, an energetic sales team with 6 sales person. Our factory is total 8800m2.

5 projects can be produced at the same time. Customize service are provided perfectly according to customers need. Drawing for product and foundation can be send. Our engineers can be on site for installation and training.

With CE and ISO certificates, patented products and obtained production licenses, our machines have been exported to 106 countries in Asia, Middle East, America, and Europe and so on.

With development over the years, we continue to develop new products with the support of research and development teams, more advanced machines like laser cutting machine, automatic robot welding machine, laser rust remover and so on. In conclusion, it's very wise to choose us as your partner.

If you have any related inquiry or custom order, please do not hesitate to let us know. We are looking forward to have the cooperationwith you in the near future.

FAQ

FAQ

Q: Are you factory or a trading company?A: We are factory and a professional manufacture of concrete batching plant and cement silos.

Q: What's your advantage?

A: We are a young and active thinking group, we can design and also can advise special design according the clients detail

requirements.

Q: How about your producr quality?

A: We are a factory that only do export, we must keep the high quality product to reduce the after-sale service cost.

Q: Do you supply training and after-sale service?

A: Yes,we will supply installation and training on site and also we have a professional service team that can solve all the

problems as fast as possible.

Q: How about your price?

A: We will promise that you will get what you pay.

Q: Do you have CE certificate for your concrete batching plant / cement silo?

A: Yes, we have. Both are our patent products, certificated by CE.

Contact me

Recommend Products