Single and Double PE Coated Paper Cup Machine Automatic Double Wall Paper Cup Making Machine Disposable Machine Make Cups Paper

1 set(s)Minimum order

Product Type:

Paper Cup Machine

processing type:

Paper cup forming machine

place of origin:

Zhejiang, China

brand name:

Mingyuan

voltage:

220V/380V

power(w):

12KW

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Product Type | Paper Cup Machine |

|---|---|

| processing type | Paper cup forming machine |

| place of origin | Zhejiang, China |

| brand name | Mingyuan |

| voltage | 220V/380V |

| power(w) | 12KW |

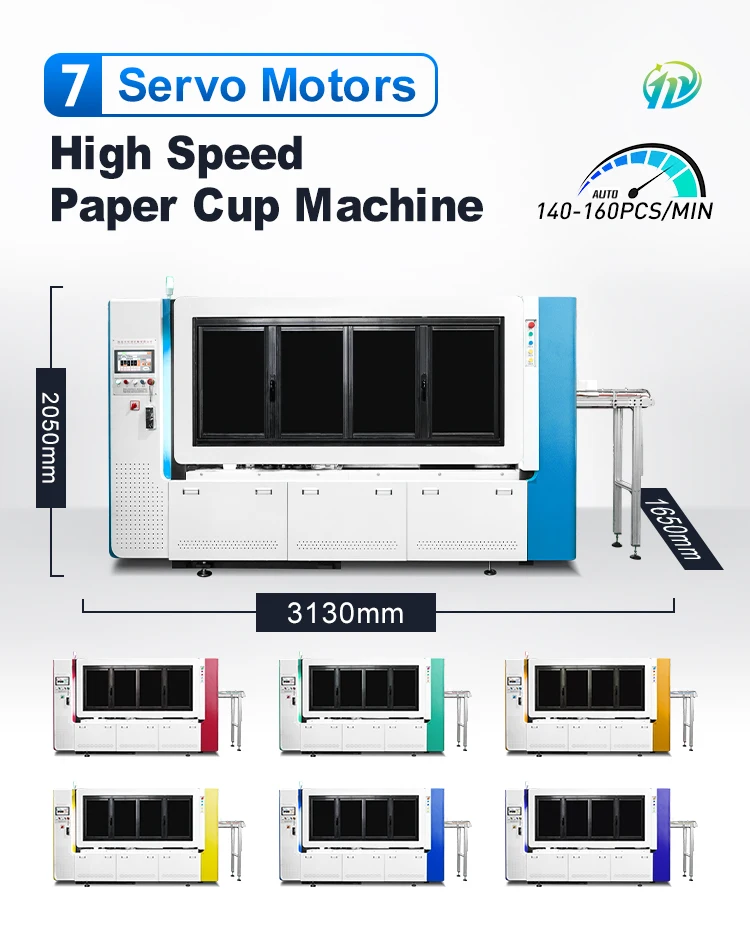

| dimension(l*w*h) | 3230x1750x2250mm |

| warranty | 2 years |

| production capacity | 140-160 pcs/min |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | PLC, Gear, Gearbox, Other, Pressure vessel, Engine, motor, Pump, Bearing |

| Weight (KG) | 3000 |

| Cup Side Welding | Ultrasonic heater |

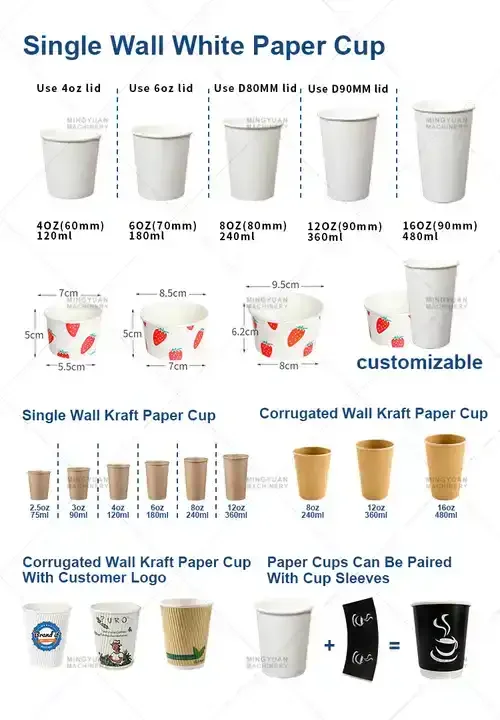

| Paper Cup Size | 1.5-16 oz |

| Raw Material | One or two side PE coated paper |

| Suitable paper weight | 140-350gsm |

| Power Source | 50/60HZ,380V/220V |

| Total Weight | 3000 kgs(machine)+100kgs(cup-collecting device) |

| Cup Bottom Heating | Heater Knurling |

Product Detail

Color customization

The shell of the paper cup machine can be customized in various colors to meet customer requirements.

Machine | MYC-160S | ||||||

Cup Side Welding | Ultrasonic heater | ||||||

Cup Size | 1.5 ~16 0Z | ||||||

Rated Speed | 140-160 pcs/min | ||||||

Suitable Paper Weight | 140g-350g | ||||||

Total Weight | 3000 kgs(machine)+100kgs(cup-collecting device) | ||||||

Package Size(L*W*H) | 3230x1750x2250mm | ||||||

OPTIONAL EQUIPMENT

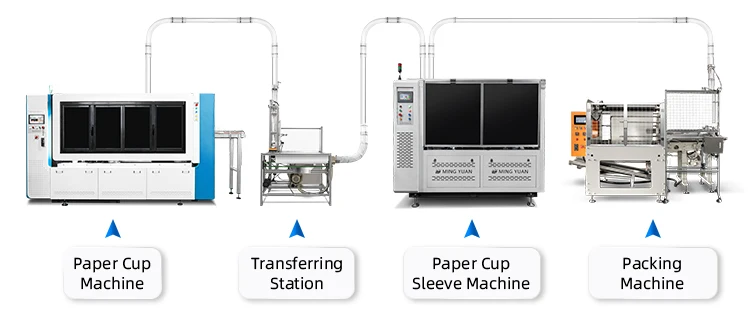

PAPER CUP PRODUCTION LINE

Paper cup machine procurement program

Option 1:If you only make single-wall cups, my recommendation is to buy a paper cup machine + cup holder + a packaging machine(No need to buy transfer station + double-wall paper cup machine)

Option 2:If you need to make a double-wall paper cup machine, my recommendation is to buy a paper cup machine + transfer station + cup sleeve machine + cup holder + packaging machine

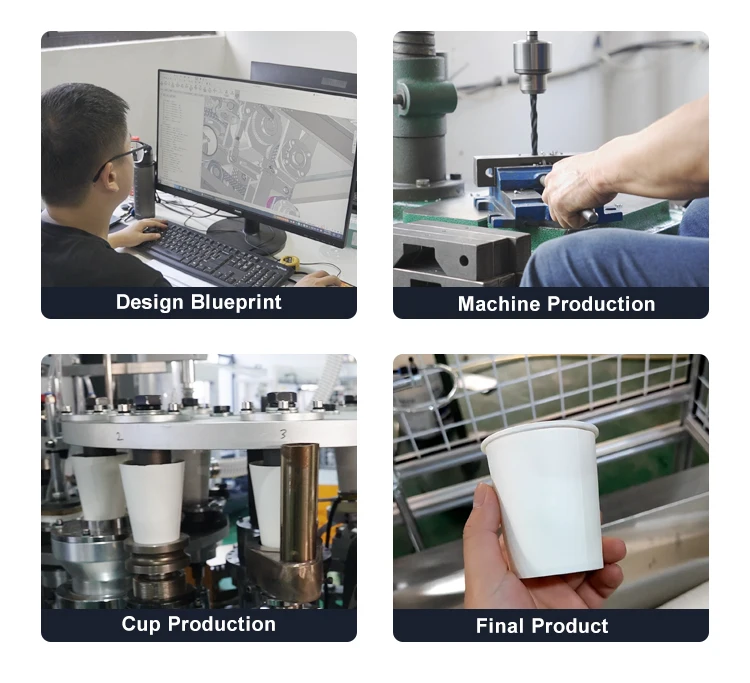

ORDER PRODUCTION PROCESS

• Design Blueprint: Develop a detailed blueprint of the cup machine according to customer needs.

• Machine Production: Manufacture, assemble and fully test the paper cup machine.

• Cup Production: Conduct small-scale trial production of paper cups after machine debugging.

• Final Product: Display the finished paper cup machine and paper cups, and conduct quality inspection.

• Machine Production: Manufacture, assemble and fully test the paper cup machine.

• Cup Production: Conduct small-scale trial production of paper cups after machine debugging.

• Final Product: Display the finished paper cup machine and paper cups, and conduct quality inspection.

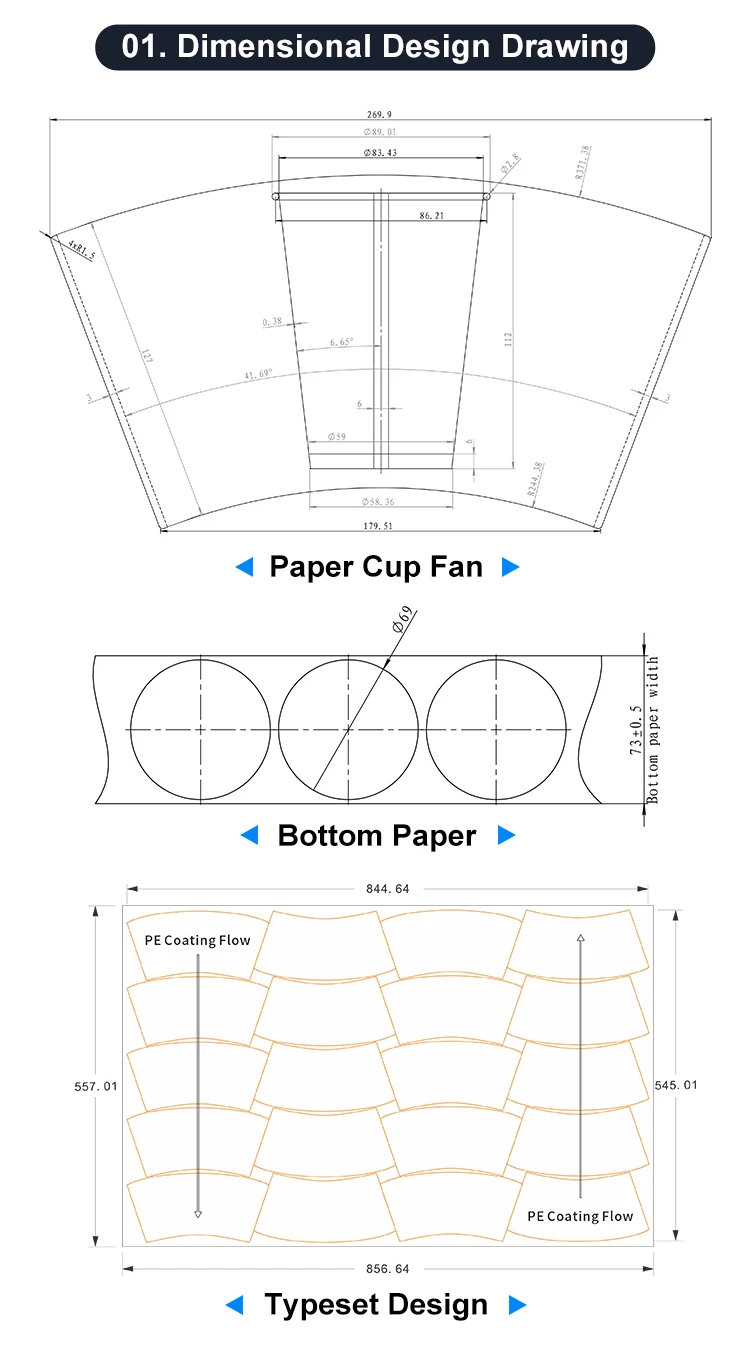

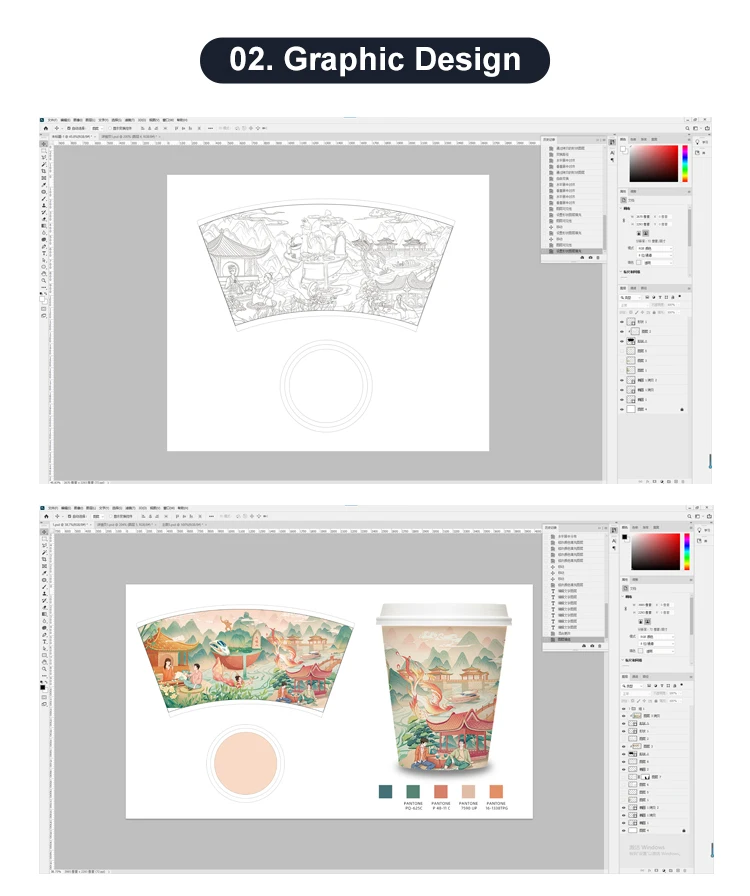

PAPER CUP SIZE PRINTING DESIGN

Dimensional Design Drawing

First, engineers design the paper cup fan and bottom paper drawings according to customer samples, and then draw the typeset design drawings.

Graphic Design

We first design a draft based on customer needs and make adjustments based on feedback. Then, we use professional tools to color the paper cup fan and the bottom paper.

Final Product

Once the design is completed, we will produce a small number of samples for review and send physical samples or electronic sample drawings to ensure that the final design fully meets the customer's expectations.

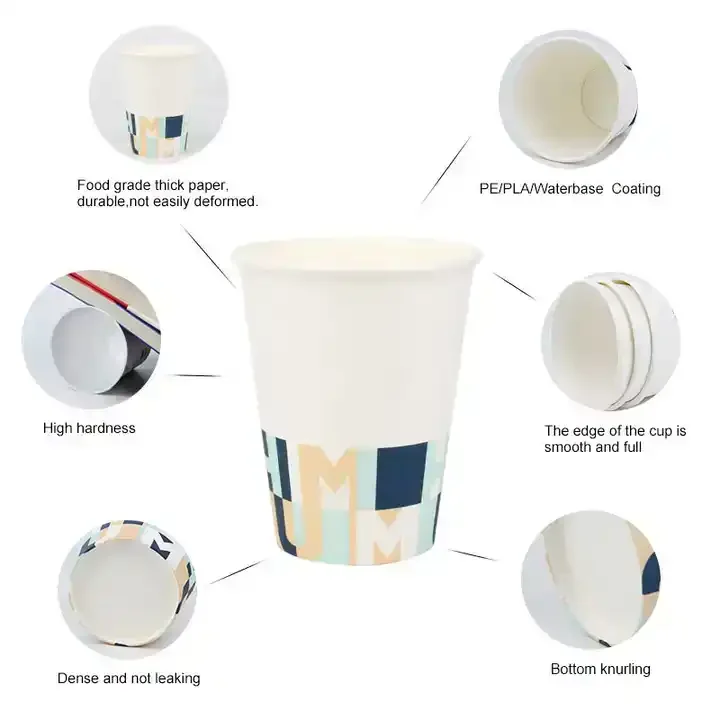

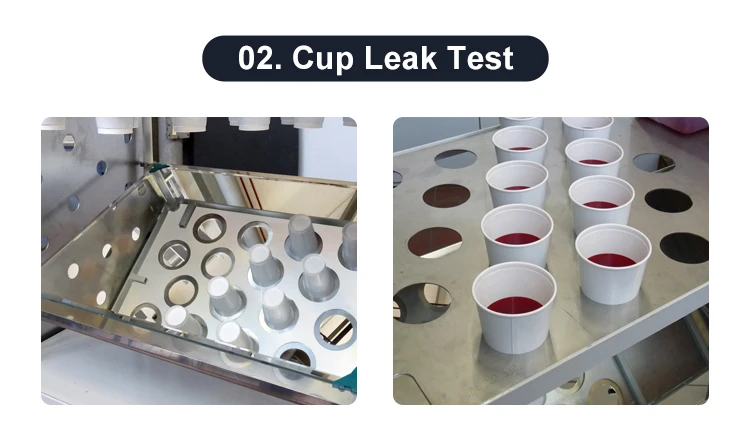

PAPER CUP FINISHED PRODUCT TEST

Cup Dimension Check

We perform detailed dimensional measurements on the produced paper cups to verify the accuracy of the paper cup machine and ensure that the dimensions of the paper cups meet the requirements without significant deviation.

Cup Leak Test

We conduct rigorous leak tests on paper cups, observe the bottom seal effect through mirrors, and test multiple paper cups to ensure sealing performance and durability.

AFTER SALES SOLUTIONS

Professional team to help you solve the problem

We provide our customers with a comprehensive after-sales service, including installation and commissioning services, operational training, two-year warranty, regular inspections, problem solving support, operation and maintenance manuals and on-site engineer service to ensure efficient operation of equipment throughout the process.

Selling Point of a Product

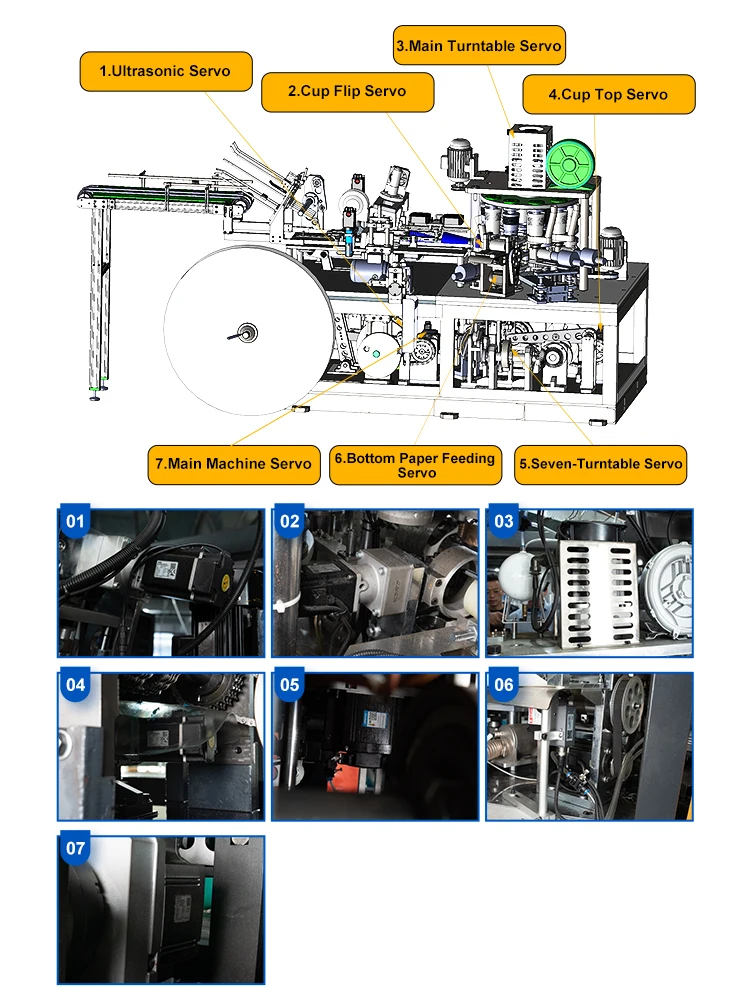

Paper Fans Feeding Unit

Feeding the paper fan automatically and save labor costs

Ultrasonic Heater Svstem

our machine will has both ultrasonic and hot air heating for making themid sealing of the cup.

Double Turnplate Design

Top rim curling and bottom sealing in separated turnplate which cangreatly improve the machine stable.

Integral Mould Head

The whole mold head with 10pcs and adopt aluminum material comparewith the single plate only 8pcs bakelite separable material ,the finishedpaper cup not easy be dirty.

Two Times Top Curling

we use two times rim rolling design. Rolling the rim two times and makethe cup rim harder, the edge will goes inside deeper, the rim will notopen easily.

Bottom Hot Air Pre-heaters

1 hot air bottom paper folding heater ,and 2 pcs bottomhot airpre-heaters can ensure bottom sealing no leakages issuesin high speed

Company Strength

FAQ

Q1. Are you trading company or manufacturer?

A:we are one of the leading manufacturer of the paper cup machine, Plastic lid machine, paper plate machine etc paper product machinery in China.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.

Q2. Do you have quality certificate?

A:we have got the ce certificate for our machine.

Q3. What's the delivery time?

A:Around 20~30 days, however, based on order.

Q4. where is your factory location?

A:we are locate in Henghe industrial zone, feiyun street, ruian city, zhejiang province, china. our nearest high way exit is feiyun, our nearest train station is ruian station, our nearest airport is wenzhou airport.

Q5.How does your factory do regarding quality control?

A:Quality is priority. Our Factory always attach great importance to quality controlling from the very beginning to the very end:

1).Skilful workers care every details in handling the producing and packing processes;

2).Quality Control Department specially responsible for quality checking in each process.

Q6. What terms of payment you usually use?

A:T/T 30% deposit and 70% before machine loading, Western Union, L/C at sight.