Specialized Fineness Can Be Adjusted with Little Noise and Vibration Raymond Mtw218 Grinding Mill Iron Ore

US $12,990.00-13,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, Bearing, motor

Type:

Raymond Mill

Motor Type:

AC Motor

Capacity(t/h):

20-50

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, motor |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 20-50 |

| Place of Origin | Henan, China |

| Brand Name | TYM |

| Dimension(L*W*H) | 13922*9810*13226MM |

| Weight | 66000 KG |

| Warranty | 1 Year |

| Product name | European Version mill |

| classifier motor | 75-90KW |

| roller | 5SET |

| Color | Customer Requirement |

| grinding ring diameter | 2150MM |

| host speed | 65R/M |

| max input size | 50MM |

| output fineness | 1.6-0.055MM |

| main blower motor | 280KW |

| blower motor | 385KW |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Construction works , Energy & Mining |

| Showroom Location | Egypt, Viet Nam, Philippines, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia |

| Warranty of core components | 1 Year |

| Condition | New |

| Marketing Type | New Product 2024 |

Product Detail

Product Introduction

European version mill

MTW series grinding mill called the European mill, which has a number of independent intellectual property rights, featured by small occupation area, low consumption, high yield, good appearance and environmental protection. So that it has been extensively used to grind and process materials in metallurgy, building materials and chemistry industries. European mill is widely applied to process non-inflammable and none-explosive materials with Mohs hardness less than 9.3 and humidity under 6%.

Technical advantages of our MTW mill:

1.Adopting bevel gear integral drive-system achieves small energy loss and high efficiency.

2.Inner automatic Thin-Oil lubricating system, make the operation more convenient reliable.

3.Arc air channel guarantees small loss of the air volume and good material flow.

4.Cambered shovel with renewable edge.

5.Streamlined design of classifier's top cabinet makes resistance greatly reduced.

6. Higher powder grinding efficiency and lower cost.

7.No resistance snail shell (small checking door so that there is not an eddy air flow)

8.Output size is adjustable and controllable the powder selecting efficiency is higher than before.

9. Roller device adopts linkage pressurization which is using the most advanced technology.

The classifier adopts a built-in large blade cone turbine classifier, and the particle size of the finished product can be adjusted within 60-400 mesh, which improves the classification.

The bevel gear integral transmission can achieve higher transmission efficiency, save the space and lower the investment costs.

Thin oil lubrication (gear oil):

The lubrication area of bearing and thin oil is larger; replace oil in three or four months, maintain equipment and reduce customer cost.

The shovel is made of high manganese steel, and the theoretical life is 5~10 times that of the old one.

The curved surface can be replaced by blade, which is convenient and cost saving. The combined installation precision of the shovel blade is high.

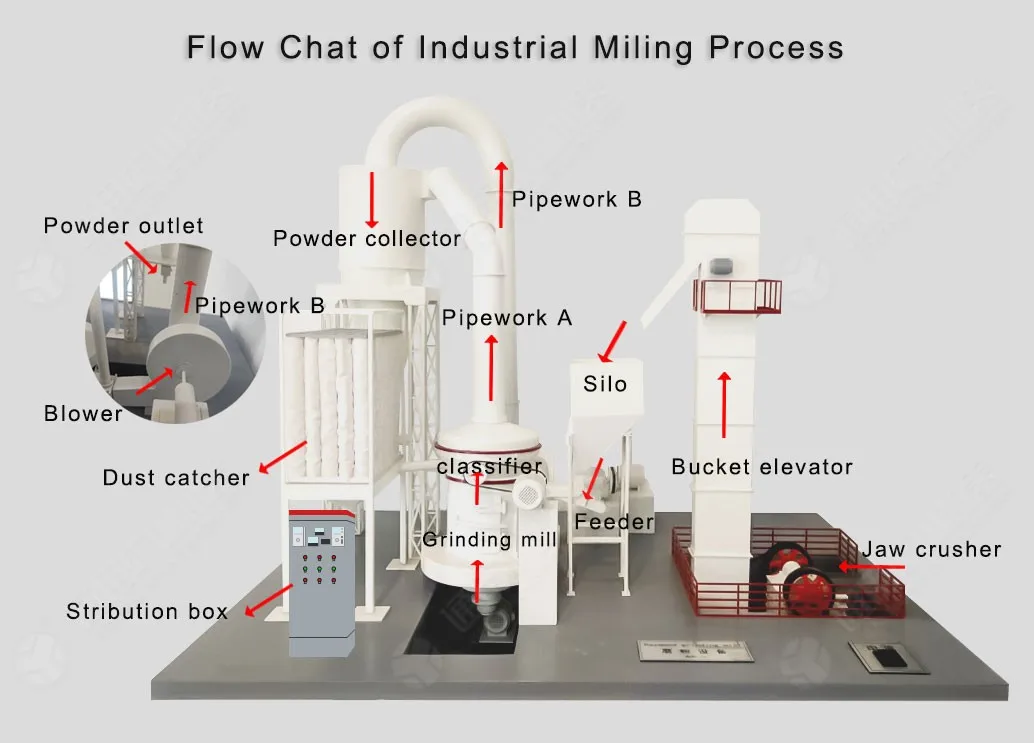

Working Principles

Working process of European mill: the center axis is driven to rotate by the bevel gear and the upper axis end connects with grinding roller hanger where the grinding roller device is placed forming a swinging fulcrum. The grinding roller not only rotates around the central axis but also around the grinding ring, at the same time the grinding roller rotates itself by friction. The blades are placed under the hanger and are in the lower grinding roller end. The rotation of blades and grinding rollers throws materials up to the gap between grinding ring and rollers forming bedding layer which are ground by outward centrifugal force (extrusion force) from grinding roller rotation.

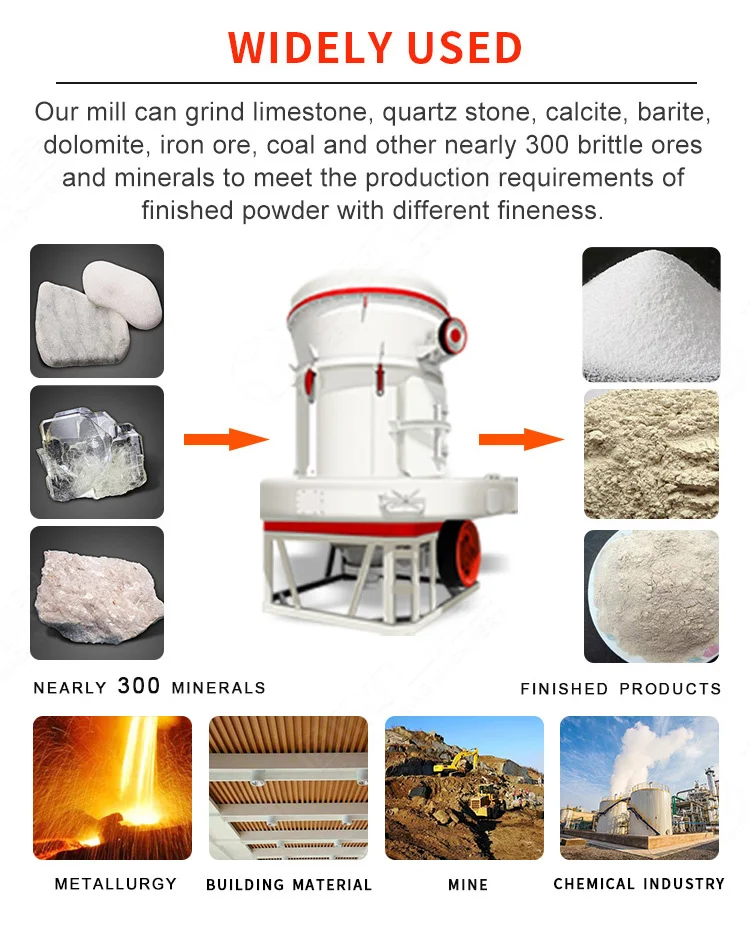

Application materials and fields

It is mainly used in the field of metallurgy, building materials, chemicals, mining and such mineral materials for grinding process. This mill can grind materials with Mohs hardness below 9.3 and humidity below 6%, variousnon-tlammable mineral materials„, such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble,ceramics, bauxite, manganese ore, iron ore, copperore, phosphate rock, iron oxide red, Zircon sand, slagand so on.

Technical Parameter

Name | Grinding roller number | Grinding ring inside Diameter (mm) | Main unit rotation speed (r/min) | Max. feeding size (mm) | Finished Size (mesh) | Capacity (t/h) | Weight (t) | |||||||

MTW110 | 4 | 1103 | 130 | 25 | 80-425 | 2.5-6.6 | 13.5 | |||||||

MTW138 | 4 | 1380 | 96 | 35 | 80-425 | 6.5-15 | 28.5 | |||||||

MTW178 | 4 | 1750 | 75 | 40 | 80-425 | 11-25 | 46 | |||||||

MTW215 | 5 | 2150 | 65 | 50 | 80-425 | 20-50 | 66 | |||||||

MTW1420 | 4 | 1420 | 103 | 30 | 80-425 | 3-10.5 | 22.5 | |||||||

MTW1720 | 5 | 1720 | 92 | 40 | 80-425 | 5-18 | 39 | |||||||

Our Customers Site

Our factory is specialized in the production of Raymond grinding mill for more than 20 years, is the leading brand in the industry. We have accumulated rich practical experience, and the case sites cover more than 30 countries in the world, including mining, cement, metallurgy, chemical, construction waste and other fields. We can provide EPC project general contracting and other complete solutions.

This is our limestone grinding mill site in Zambian!

The customer's requirements:

Raw material: limestone, capacity: 25 tons/hour, finished products: 200mesh.

Raw material: limestone, capacity: 25 tons/hour, finished products: 200mesh.

Equipment configuration: 2 sets YGM160.

This is our Kaolin grinding mill site in Thailand!

The customer's requirements:

Raw material: Kaolin, capacity: 3 tons/hour, finished products: 325mesh.

Raw material: Kaolin, capacity: 3 tons/hour, finished products: 325mesh.

Equipment configuration: MTW110.

This is our bentonite grinding mill site in Lebanon!

The customer's requirements:

Raw material: Bentonite, capacity: 8 tons/hour, finished products: 200-250mesh.

Raw material: Bentonite, capacity: 8 tons/hour, finished products: 200-250mesh.

Equipment configuration: MTW110.

This is our bentonite grinding mill site in Columbia!

The customer's requirements:

Raw material: Gypsum, capacity: 8 tons/hour, finished products: 300mesh.

Raw material: Gypsum, capacity: 8 tons/hour, finished products: 300mesh.

Equipment configuration: YGM1500.

Company Information

Since in 2004, Zhengzhou General Mining Machinery Co.,Ltd has been the professional manufacturer of Grinding Mill, crushers and sand making machines,etc.

TYM is committed to helping more users around the world to obtain higher profits and faster return on value. Our main products are European Version Grinding Mill, Raymond Grinding Mill, High Pressure Suspension Roller Mill, Micro-powder Grinding Mill, Jaw Crushers, Impact Crushers, Hammer Crusher, Compound Crushers, Ball Mill, nine series of products with more than 30 kinds of specifications.

Our factory

Our factory covers an area of 120,000 square meters and manufactures TYM brand Mining Machinery,has passed international ISO:9001, GOST and CE certification.

Crushing equipment showroom!

Sand making equipment showroom!

Grinding mill showroom!

Grinding mill showroom!

CNC manufacturing shop!

Improve production efficiency!

Shorten the production cycle!

Packing & Shipping

The package of all equipment is accord with the standard protective measures.The packing is suitable for short and long distance transportation. The moisture proof, quake proof, protected against dampness, and rustproof protection measures were taken to ensure the machine shipping to customers safely. All the machine will be packaged by plastic film.

Plastic film packaging

Large items will be wrapped in plastic film, such as jaw crusher, impact crusher, cone crusher, main mill, pipe, etc.

Box wooden packing

Small parts will be packed in wooden box, such as bolts, rubber sleeves, springs, etc

Certifications

Our Services

Warranty

100% brand new when leaving the factory. The seller guarantee quality of the machines (excluding wearing parts) for a period of one year from the date of trial run finish under our technician's guidance, but not exceed 15 months from date on which machine leaves the factory.

Pre-sale services:(1) Device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program.

Sale services:

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

Sales tracking :

(1) product acceptance.

(2) to help customers develop construction programs.

After-sale services :

(1) Guiding customers' installation.

(2) On-site training of operators.

(3) Complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

CLICK HERE,LET US TALK MORE DETAILS

Please give us the following details about your needs,We will give you professional advice.

1.raw materials

2.feeding size

3.discharge size

4.capacity

5. ...

1.raw materials

2.feeding size

3.discharge size

4.capacity

5. ...

Recommend Products