Steel Metal Sheet Hole Punching Machine/Turret Punching Machine/CNC Turret Punch Machine

US $56,000.00-57,000.00 / set

1 set(s)Minimum order

cnc or not:

CNC

machine type:

Punching Machine

power source:

Mechanical

place of origin:

Shandong, China

brand name:

puhua

dimension(l*w*h):

design

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| cnc or not | CNC |

|---|---|

| machine type | Punching Machine |

| power source | Mechanical |

| place of origin | Shandong, China |

| brand name | puhua |

| dimension(l*w*h) | design |

| model number | AMD-357 |

| weight (t) | 14 |

| key selling points | High-accuracy |

| warranty | 1 Year |

| machinery test report | Provided |

| video outgoing-inspection | Provided |

| core components | motor, PLC |

| Condition | New, New |

| CNC or Not | CNC |

| Certification | ISO9001, CE |

| Power Source | Hydraulic, mechanical ,servo |

| Warranty | 2 years |

| Control system | Siemens, Fanuc |

| Throat depth | 1250mm or 1500mm |

| Maximum punch thickness | 6mm |

| After-sales Service Provided | Service Machinery Overseas |

| Process software | Cnckad (metalix) |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Retail |

| Showroom Location | United States, Viet Nam, Philippines, Russia |

| Marketing Type | Ordinary Product |

| Warranty of core components | 2 years |

Product Detail

Products Description

Rotary punch press CE/ISO CNC Turret Punching Machine

AMD-357 CNC turret punching machine is mechatronics automation equipment, it's widely used in the instruments and meters, chassis cabinets processing, electric control cabinet panels, battery plate, building decorative materials, auto parts, silencing plate, lamps, kitchen equipment, air conditioners and other sheet metal processing industries.

Technical Parameter

Model | AMD-357 |

Capacity | 300/500 KN |

Driving Type | Mechanical driving |

CNC System | Siemens/Fanuc |

Max. Processing sheet (Reposition) | 1000/1250/1500/1750 mm 1500/2500/4000/6000 mm |

QTY of Clamp | No.3 |

Max. Processing Sheet Thickness | 6 mm |

Max. Punch Diameter | Φ88.9 mm |

Max. Punch Hit at 1mm Pace | 400 hpm |

Max. Punch Hot at 25mm Pace | 220 hpm |

QTY of Station | No.24/32 |

Controlling Axis | No.4 |

Machine Frame | O type |

Max. Feeding Speed | 60 m/min |

Tooling Rotation Speed | 30 rpm |

Accuracy | ±0.1 mm |

Rated Power | 20 KW |

Air Pressure | 0.6-0.8 MPa |

Outline Dimension | 4490*5300*2110 mm |

Product Features

With servo motor, faster speed and higher stability

Equipped with secondary positioning system to realize processing without dead angle

With the features of automatic lubrication and minimal wear

Use casting integrated type thick turret mold disc

We adopt brush and universal ball mixer work table,can not only facilitate processing,but also can protect the plate very well.

The transmission system, electrical components, and hydraulic components all adopt internationally renowned brands

Product Application

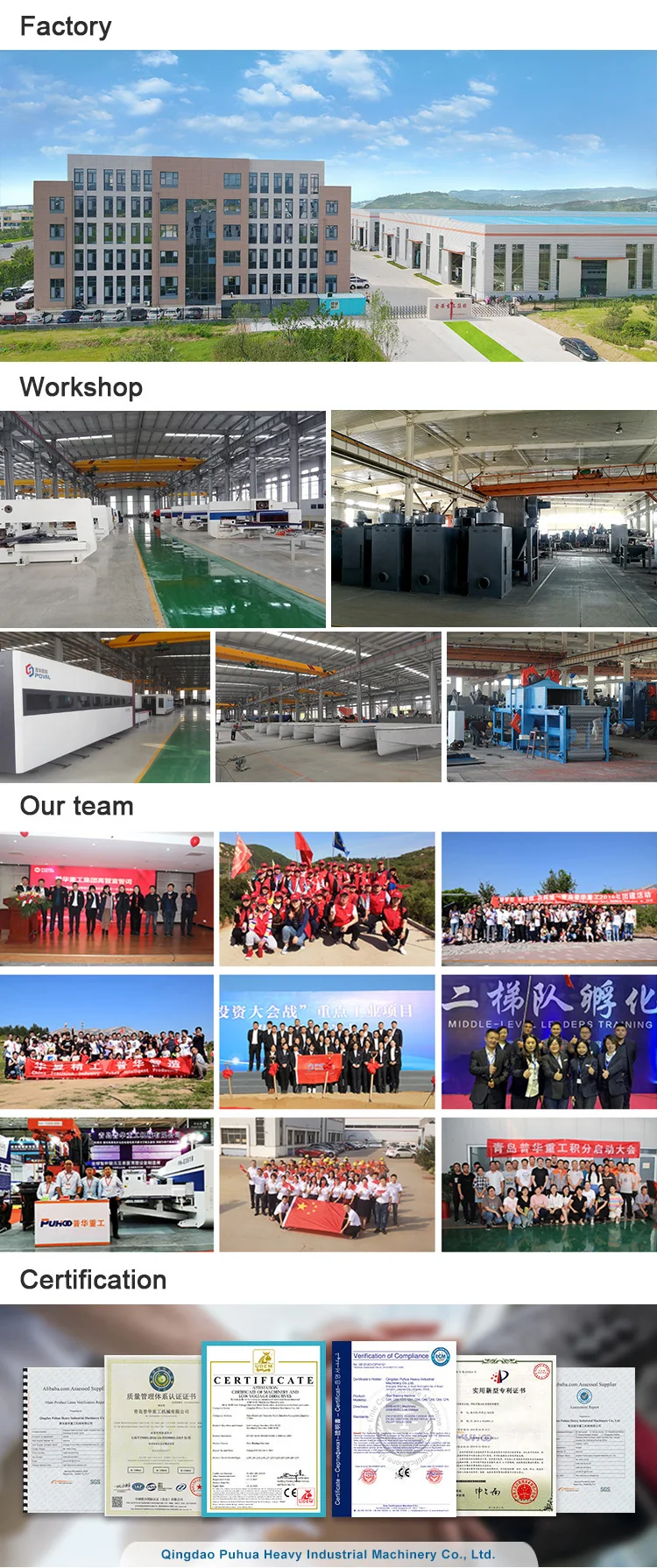

Workshop

Certifications

Product Packaging

Recommend Products

Company Profile

Qingdao Puhua Heavy Industrial Group was established in 2006. It focus on design, research, development, manufacturing and export of CNC punching machine, sand blasting booths, sand processing equipment, environmental protection equipment, a variety of shot blasting machine, including roller conveyor type, overhead chain type, hook type, tumble belt type, wire mesh type, road surface type etc. All products are professionally designed by our highly-experienced engineers with Auto CAD.

FAQ

1. What is the delivery time?

20-40 working day, based on factory’s production order conditions.

2. How to installation machine?

We supply overseas service, engineer can go to your place guide installation and debugging.

3. What size machine suit for us?

We design machine following your request, usually based on your workpiece size, weight and efficiency.

4. How to control the quality?

One year warranty,and 10 teams QC to check every part from drawing to machine finished.

Our service:

1.Machine guarantee one year except damage by human wrong operation caused.

2.Provide installation drawings, pit design drawings, operation manuals, electrical manuals, maintenance manuals, electrical wiring diagrams, certificates and packing lists...

3.We can go to your factory to guiding installation and train your stuff.