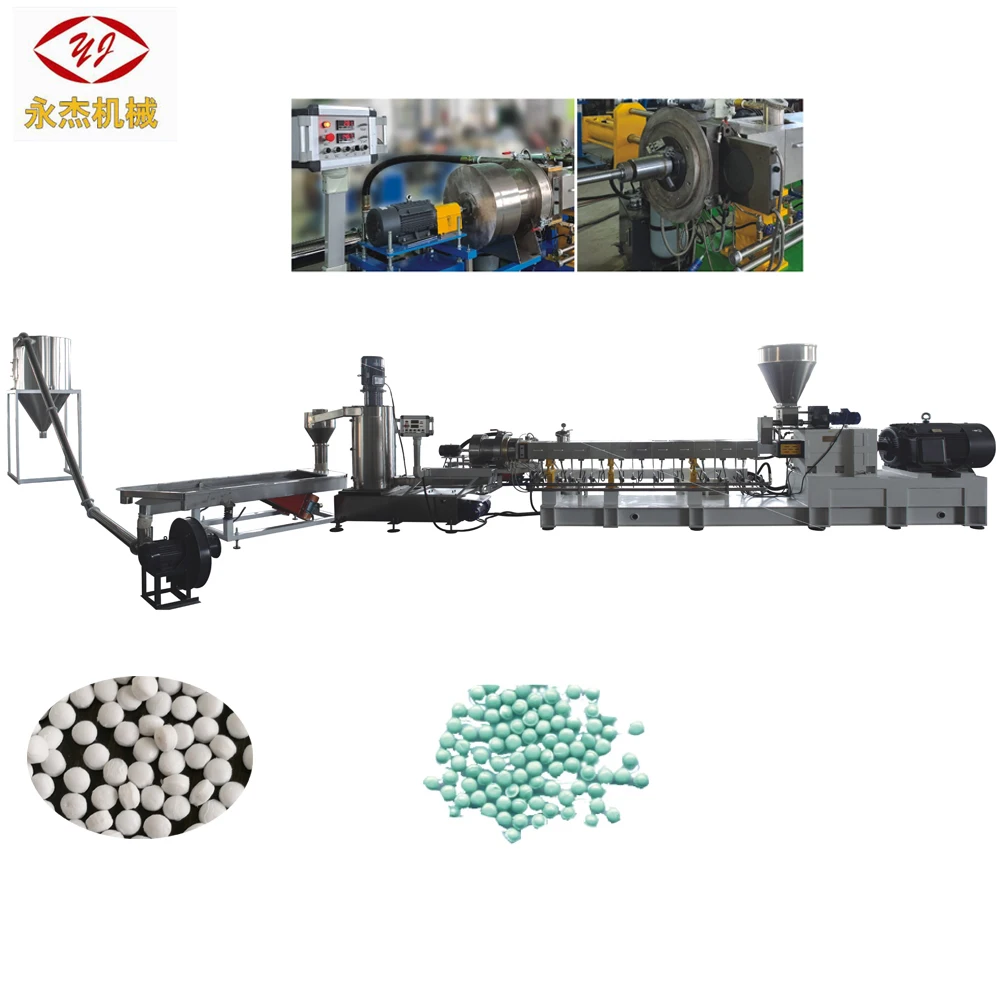

Talc/caco3 Filler Color Masterbatch Production Line Machine Plastic Extrusion Machine

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PP/PVC/WPC/PE/ABS/XPS/Polystyrene |

|---|---|

| application | Granules |

| Screw Design | Double-screw |

| twin screw type | Co-rotating Parallel Twin-screw |

| Screw Material | W6Mo5Cr4V2 |

| screw diameter (mm) | 50.5 mm |

| screw l/d ratio | 40-64 |

| Screw Speed (rpm) | 500 rpm |

| place of origin | Jiangsu, China |

| brand name | YongJie |

| voltage | 380V 50HZ |

| dimension(l*w*h) | Model |

| power (kw) | 45 |

| warranty | 1 Year |

| key selling points | Energy saving |

| video outgoing-inspection | Provided |

| core components | motor, PLC, Gearbox |

| machinery test report | Provided |

| Raw material | PP/PE+caco3, or talc |

| Color | any color as your require |

| L/D | 32-64 |

| RPM ( r/min) | 400/500/600/800 |

| T/N | 5.9/4.7/5.0 |

| Torque(N.m) | 2815/2250/2365/2250 |

| Certification | CE ISO9001 |

| Cutting system | Water ring or air cooling die face cutting |

| Barrel material | 45#forged steel with the abrasion-resistant alloy 101 (Ni-Fe-Cr-W) |

| Barrel section | 12 |

| Marketing Type | Ordinary Product |

| Condition | New |

| Showroom Location | None |

| Applicable Industries | Manufacturing Plant |

| Warranty of core components | 1 Year |

| Weight | 1 KG |

Product Detail

Talc/caco3 filler color masterbatch production line machine For Plastic Extrusion

Brief introduction: Water ring cover is aluminum casting, precision machining of internal flow channel and thickness of water, the distance of cooling material is long, can effectively avoid secondary adhesion.

Apply to: The production of high-quality talc/caco3 filler masterbatch mixing, compounding and granulation.

Main technical data of various model of filler color masterbatch machine plastic extrusion machine

|

Model type |

Series |

Barrel Diameter (mm) |

Screw Diameter (mm) |

Screw L/D |

screw speed n(r/min) |

Main motor power(Kw) |

Screw torque T(N.m) |

Torque rating (T/A3) |

Typical production capacity (kg/h) |

|

SJSL20 |

A/B |

22 |

21.7 |

32-44 |

500/600 |

4/5.5kw |

30/30 |

|

|

|

SJSL-36 |

A/B/C/D |

36 |

35.6 |

32-48 |

400/600 |

11/15/18.5/22 |

125-225 |

4.6-8.3 |

30-120 |

|

SJSL-51 |

A/B/C/D |

51 |

50.5 |

32-52 |

500/600 |

45/55/75/90 |

405-680 |

5.1-8.5 |

120-400 |

|

SJSL-65 |

A/B/C/D |

63 |

62.4 |

32-64 |

500/600 |

75/90/110/132 |

680-1200 |

4.8-8.5 |

180-750 |

|

SJSL-75 |

A/B/C/D |

72 |

71 |

32-64 |

500/600 |

110/132/160/250 |

995-1890 |

4.6-8.7 |

300-1200 |

|

SJSL-95 |

A/B/C/D |

94 |

93 |

32-64 |

500/600 |

250/315/450/550 |

2260-4510 |

4.7-8.7 |

700-2500 |

|

SJSL-135 |

A/B/C/D |

135 |

133 |

32-48 |

400/500 |

550/750/900/1200 |

6200-10800 |

4.4-7.7 |

1550-6500 |

Application for water-ring hot face production line

1. Filling master batch: PE, EVA, etc. + caco3, talc, filling modified and carbon black etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, insulation material, crosslinking material,

cable coating material , thermal contraction pipe material.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic

elastomer, EVA and hot melt additives.

4. Color mater batch: PE, ABS, PS, EVA master batch, etc.

5. ABS, EVA flaming retarding master batch, etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

Auxiliary

|

Water-ring cover |

|

|

pelletizer |

|

|

Centrifugal dehydrator |

|

|

Vibrating sieve |

|

|

Bin |

|

FAQ

1. Are you a factory or trading company?

Both.

2. Where is your factory located? How can I visit there?

Our factory is located in industrial centralized area of Moling town, Jiangning, Nanjing, China.

(1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

3. What's your advantages?

(1) Excellent quality control

(2) First-class service

(3) Professional Tech. and R&D team

(4) Quick manufacturing time

(5) Quite competitive price

4. How long is the delivery time?

Under normal conditions, products are delivered within 35 days.

5. How can I know the stauts of my order?

We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

6. how long is the warranty?

We can offer one-year warranty for the whole machine.

Contact us

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd

Nanjing Yongjie Chemical & Machinery Co.,Ltd

Add. : No.9 Lanxia Road, Moling Industrial Concentration Area, Jiangning District,211165, Nanjing, China

Tel.: 0086 25 52750152

Fax: 0086 25 58736139

Contact person:Annie

Mob/Whatsapp/Line/Wechat/Yahoo:0086 15026670964

Skype: annie at njyjhg.com(same as email)

Website: www.njyjhg.com