Three Layers HDPE Pe PIPE Making Machine Plastic Water Pipe Extruder Machinery Equipment Making Machine

US $15,000.00-35,000.00 / set

1 set(s)Minimum order

plastic processed:

PE, PP, PPR, HDPE/PP, PE/PP

application:

PIPE

Screw Design:

Single-screw

Screw Material:

38CrMoALA

screw diameter (mm):

65

screw l/d ratio:

30:1

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PE, PP, PPR, HDPE/PP, PE/PP |

|---|---|

| application | PIPE |

| Screw Design | Single-screw |

| Screw Material | 38CrMoALA |

| screw diameter (mm) | 65 |

| screw l/d ratio | 30:1 |

| Screw Speed (rpm) | 300 rpm |

| place of origin | Shandong, China |

| brand name | FULLWIN |

| voltage | 380V or customized |

| dimension(l*w*h) | depend on design |

| power (kw) | 80 |

| warranty | 1 Year |

| key selling points | Automatic |

| video outgoing-inspection | Provided |

| core components | Bearing, motor, Gear, Screw |

| machinery test report | Provided |

| Raw material | PPR PE HDPE |

| Usage | transportation Pipe |

| Product Type | pipe |

| Color | Customer Choice |

| Inverter | ABB Brand |

| Motor | SIEMENS Brand |

| Capacity | 200-500kg/h |

| Pipe diameter | 160-630mm |

| Cooling way | Recycling Water |

| Screw type | single screw |

| Condition | New |

| Showroom Location | United States, France, Brazil, Peru, Thailand, Morocco, Kenya, Argentina, UAE, South Africa, Kyrgyzstan, Nigeria, Uzbekistan, Japan |

| Warranty of core components | 1 Year |

| Weight | 6000 KG |

| Applicable Industries | hotels, Building Material Shops, Manufacturing Plant, Farms, Home Use, Retail, Construction works , Oil transportation |

Product Detail

Products Description

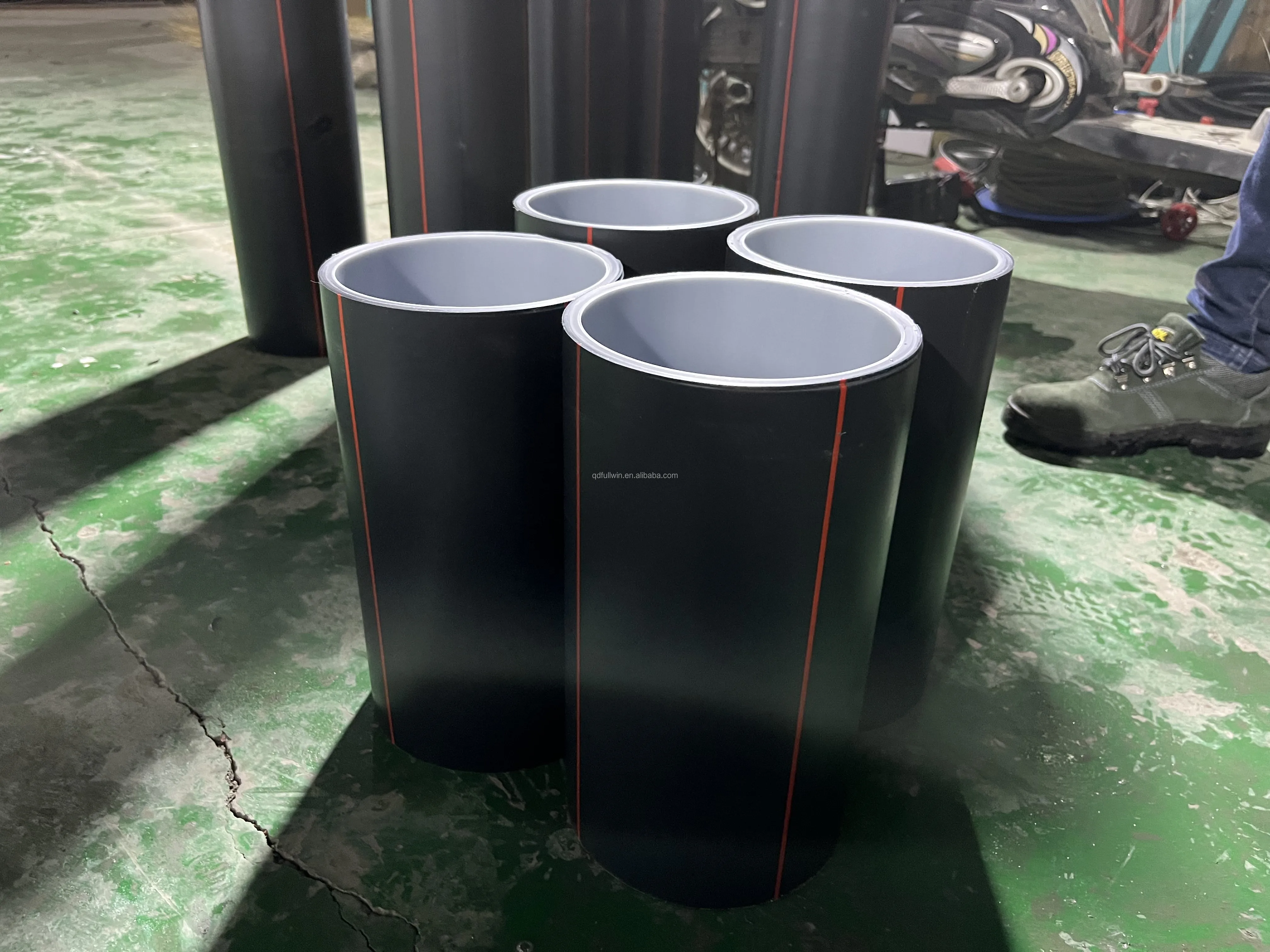

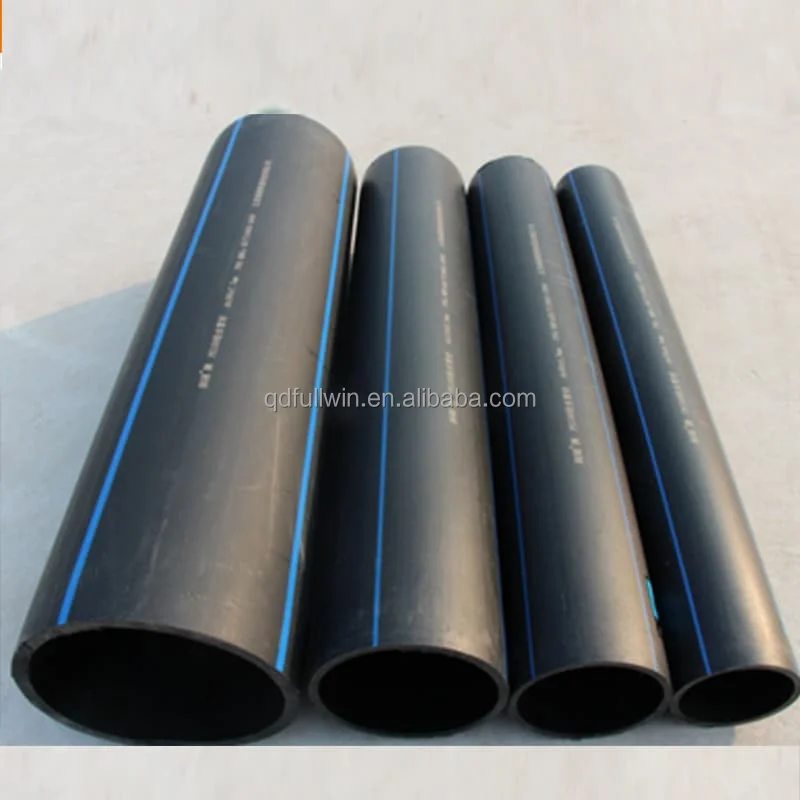

Plastic Pipe Making Machine PPR PE HDPE Pipe Extruding Machine for Sale

PE/PP/PPR pipe production line,can be used to produce PPR hot and cold water pipes,PE pipe,silicon core tube,the production line can be used to produce a single extruder monochrome tube,can also be used to produce multiple extruders through the co-extrusion head multi-layer color tube.

PE/PP/PPR pipe production line,can be used to produce PPR hot and cold water pipes,PE pipe,silicon core tube,the production line can be used to produce a single extruder monochrome tube,can also be used to produce multiple extruders through the co-extrusion head multi-layer color tube.

The commonly used PE irrigation pipe pressure range is between 0.6-1.6MPa, the color is mostly black or white, and the material is high-density polyethylene (HDPE) pipe

Process Flow:

Single screw extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank →Haul-off → No Dust Cutter → Stacker → Final Product Inspecting &Packing

Single screw extruder →Co-extruder for color string & Multi Layers → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank →Haul-off → No Dust Cutter → Stacker → Final Product Inspecting &Packing

No. | Item | Quantity |

1 | Vacuum feeding machine | 1 set |

2 | SJ65/30 Single Screw Extruder | 1 set |

3 | Die Head And Sizing Mould | 1 set |

4 | Vacuum Water Cooling Tank | 1 set |

5 | Spray Cooling Tank | 1 set |

6 | Haul off machine | 1 set |

7 | Cutting device | 1 set |

8 | Auto stacker | 1 set |

9 | Free spare parts | 1set |

Single screw extruder machine

Equipped with FULLWIN specially designed screw, the extruderhas the following advantages:

high plasticization rate, uniform melt and continuous production stability.

Die head

Die head customized according to the customer's size.

Use energy-saving rock wool heating ring, which can save 30% of electricity cost.

Mould surface with Teflon material,It has high temperature and wear resistance, and does not stick to raw materials.

Vacuum water cooling tank

The water tank is equipped with a vacuum pump and water pump to enable better shaping and cooling.

Spray water cooling tank

Equipped according to pipe diameter to provide better cooling

Haul off machine

A variety of transmission methods provide forward power for the pipe, and equipped with a meter counter

Cutting machine

Automatic fixed-length cutting,smooth surface after cutting

Auto stocker

Keep finished products

Winding machine

Powerful torque motor rolls pipes into rolls

In order to better give you professional answers, when sending the inquiry, please describe your parameters or technical

requirements (such as: processing materials, output size, capacity, etc.) and attach your contact information (such as phone number, e-mail, facebook, whatsapp, wechat, etc.)

requirements (such as: processing materials, output size, capacity, etc.) and attach your contact information (such as phone number, e-mail, facebook, whatsapp, wechat, etc.)

Contact US ↓

About us

Packing and Delivery

After sales service

- After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply,

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

water supply, labors and cranes, etc.

- Fullwin will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

- The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD100 per day for each engineer.

- Engineer will give free training lessons to labors in buyer's factory.

- If buyer doesn't request installation and commissioning by Seller's engineer in 4 months since date of bill of lading, which to be accounted all the machines has been successfully tested by buyer.

FAQ

Q:Are you machinery factory or trading company?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

Q:What`s the payment method?

A:We are machinery factory

Q:If we have very special request for the production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Jiaozhou Town, Qingdao City, Shandong Province, China. About 1 hours from Qingdao International Ariport.

Q:What`s the payment method?

A: T/T, L/C,Western Union,etc