Travertine Marble & Mango Wood End Table Travertine Marble Side End Table Italian Marble 100% Handmade Coffe Table

US $66.00-73.00 / piece

10 piece(s)Minimum order

feature:

Adjustable (other)

specific use:

Nightstand

general use:

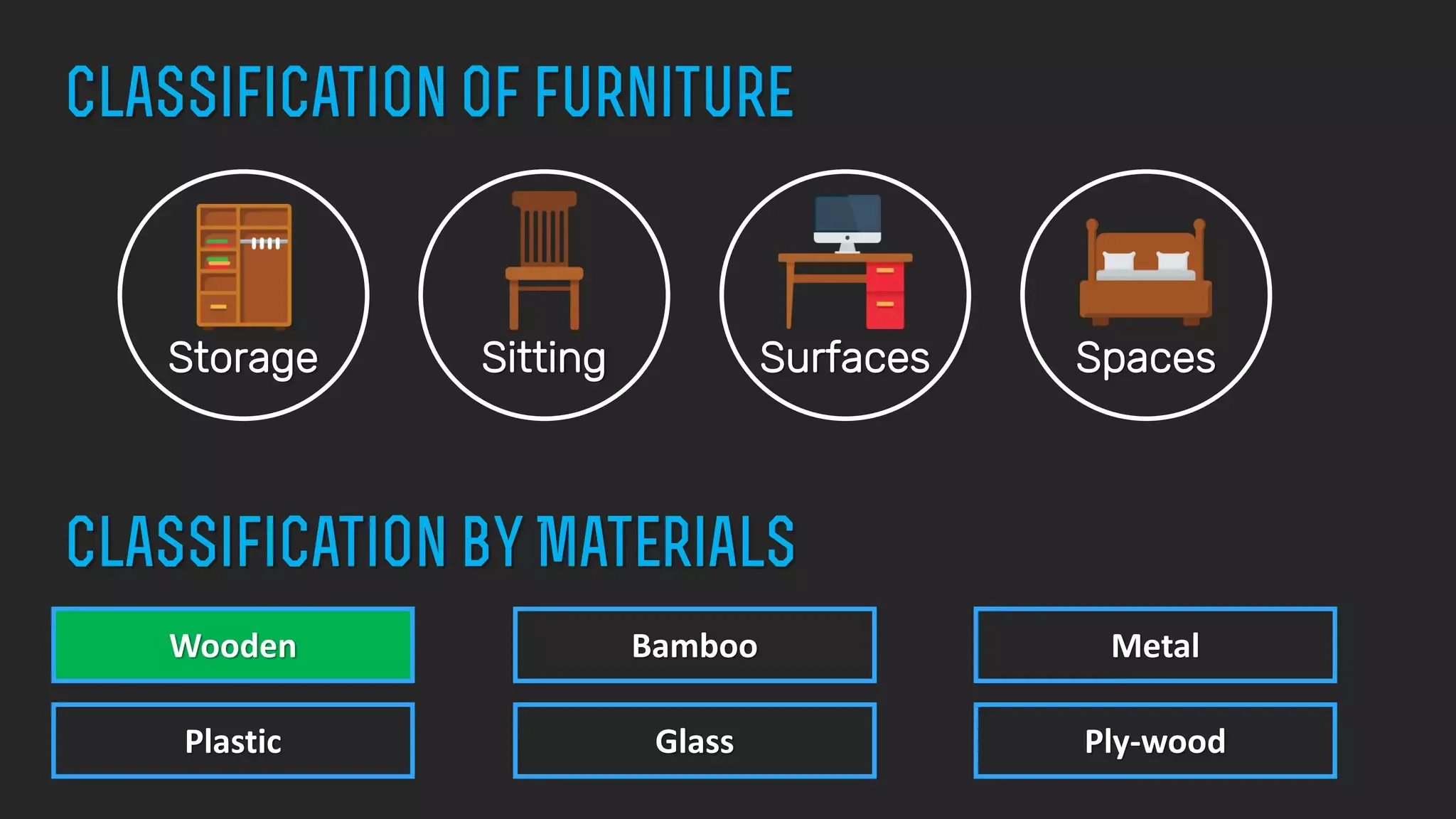

Home Furniture

type:

Bedroom Furniture

mail packing:

Y

application:

Bedroom

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| feature | Adjustable (other) |

|---|---|

| specific use | Nightstand |

| general use | Home Furniture |

| type | Bedroom Furniture |

| mail packing | Y |

| application | Bedroom |

| design style | Modern |

| material | Wooden |

| appearance | Modern |

| wood style | Solid Wood, Solid Wood |

| place of origin | Rajasthan, India |

| brand name | arihant art exim |

| model number | 8010ET03bWMb |

| Product name | Travertine marble & Mango wood End Table |

| Usage | Home Hotel Bedroom Funiture |

| MOQ | 50pcs |

| Design | Customer Designs Acceptable |

| Service | OEM ODM Customized |

| Advantage | 10 Years Furniture Experience |

Product Detail

Details Images

Products Description

PLACE OF ORIGIN | INDIA | ||||||

PRODUCT TYPE | LIVING ROOM FURNITURE | ||||||

METAL USED | IRON, WOODEN & MARBLE | ||||||

GENERAL USE | HOME FURNITURE | ||||||

SIZE | CUSTOMISED | ||||||

SAMPLE AVAILABILITY | PROVIDED IF NEED FOR PHYSICAL VERIFICATION BEFORE START THE PRODUCTION. | ||||||

LOGO | CUSTOMIZED LOGO ACCEPTED | ||||||

CUSTOM PACKAGING | ACCEPTED | ||||||

CUSTOM DEVELOPMENT | ACCEPTED | ||||||

SUPPLY ABILITY | 10000 Pcs. PER MONTH | ||||||

SHIPMENT PORT (BY SEA) | NHAVA SHEVA, MUMBAI | ||||||

SHIPMENT PORT (BY AIR) | IGI AIRPORT, DELHI | ||||||

LEAD TIME | DEPENDS ON ORDER SIZE (TO BE NEGOTIATED) | ||||||

Our Product Category

cabinet

beside table

Cabinet

Dining Table

Dining Table

Coffee table

cabinet

bar table

coffee table

Recommend Products

Company Profile

Welcome to ARIHANT ART EXIM

We are pleased to welcome you as the member of the family of ARIHANT ART EXIM, we have everything it takes to be the best manufacturing furniture products.

Let me assume that we are about you in the same way that we care about our employees and we strive to provide you with a wide range of opportunity, work experience, guidance, that will Improve the quality of your daily life.

We ensuring that the organization has honoured with all the compliance of relevant and applicable health, safety and environment laws and works towards quality management system. As well as with safeguards of workers life.

We are honoured that you have chosen us, and we look forward to rewarding and celebrating your contributions to our success.

Manufacturing Technique

The Manufacturing Process of Indian Furniture

Indian furniture manufacturing is a world of professional artisans and prosperous practices. It all starts with carefully chosen materials and ends with the design of practical yet beautifully crafted pieces. In this blog, we’ll bring you on a journey through the manufacturing process of Indian furniture, emphasizing the processes, materials, and complex elements that make it outstanding. So, let’s get started. Indian Furniture Manufacturing Process

1. Selecting the Right Materials

The journey begins with a brilliant choice of wood. Different types of wood, like Sheesham (Indian Rosewood), Teak, Mango, and Acacia, are selected for their durability and grain patterns. The selection of wood lays the foundation for the furniture’s quality and appearance.

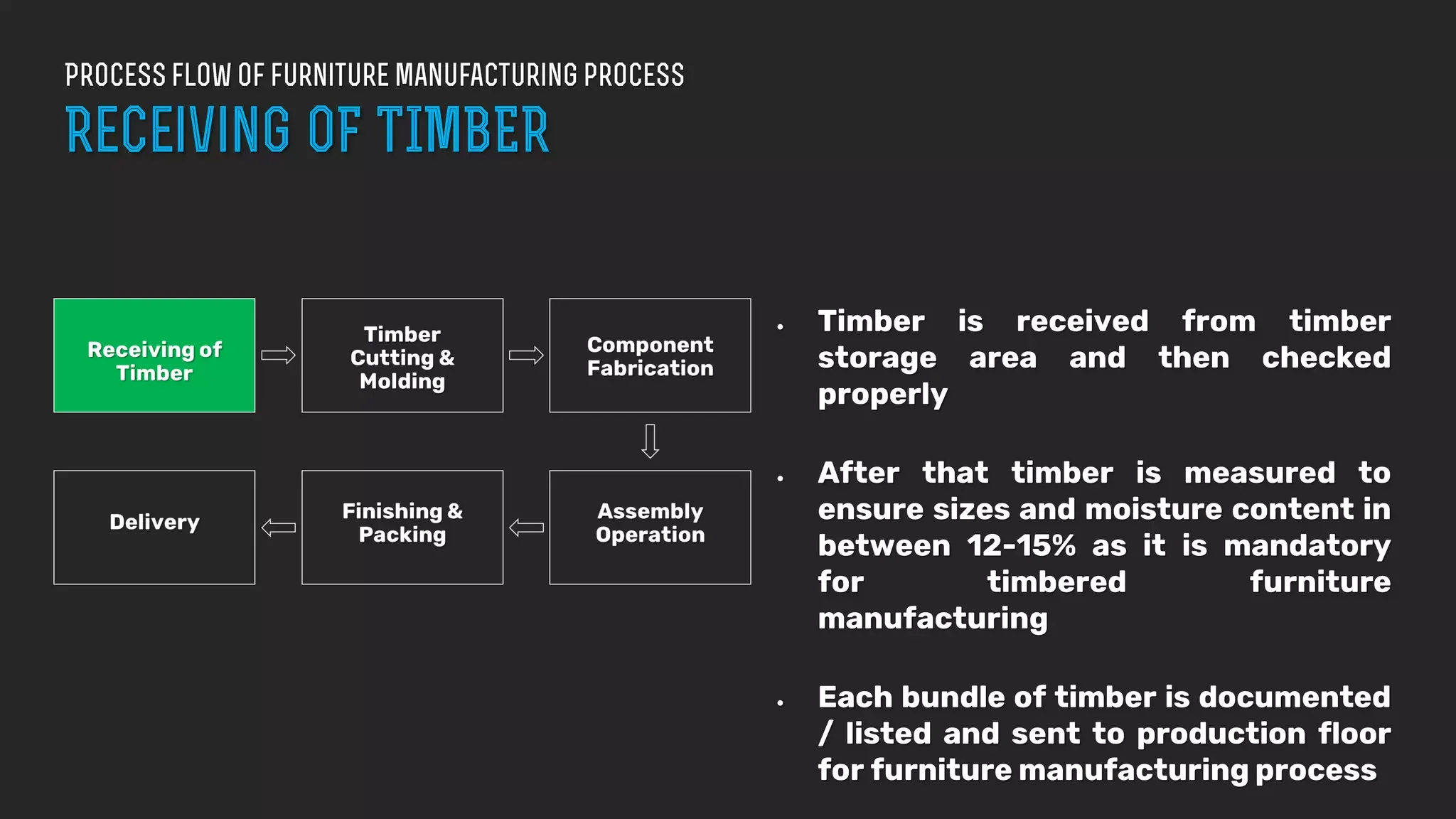

2. Seasoning the Wood

Before any carving or cutting starts, the selected wood undergoes a critical procedure known as seasoning. Seasoning involves lowering the wood’s moisture content to deter warping or breaking in the final product. Traditional methods of seasoning include air drying and kiln drying.

3. Design and Planning

The heart of Indian furniture lies in its complex structures. Skilled craftsmen specifically plan the furniture’s measurements, joints, and carving designs. These designs often attract inspiration from regional aesthetics and cultural motifs, resulting in a range of styles, from elaborate Mughal results to simpler, rustic designs.Visit for More:- wood counter design

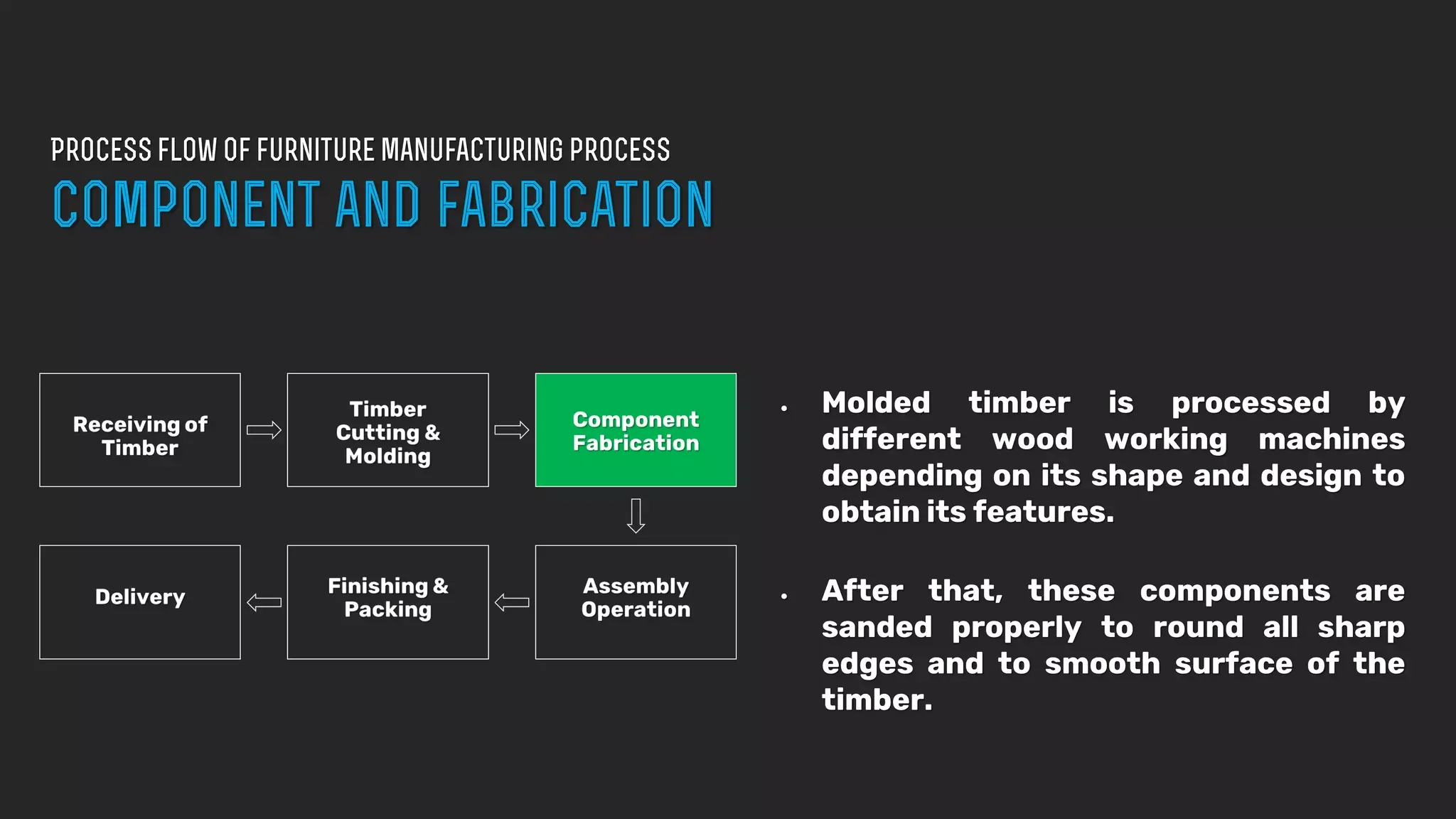

4. Hand-Crafted Precision

Hand craftsmanship is the heart of Indian furniture production. Skillful craftspeople employ traditional tools like chisels, saws, and hand planes to engrave, build, and complete each piece. It’s the artisan’s expertise that takes out the attractiveness of complex carvings, inlay work, and joinery techniques, providing Indian furniture its unique personality.

5. Joinery Techniques

The stability and longevity of the furniture rely on different joinery techniques. Mortise and tenon joints, dovetail joints, and

tongue-and-groove joints are excellently utilized to make sturdy and long-lasting pieces.

6. Inlay and Marquetry

One of the most exquisite parts of Indian furniture is the stunning inlay and marquetry creation. Artisans use materials like

bone, mother of pearl, and nerve to craft complex patterns and designs on the furniture’s character. This labor-intensive process adds luxury and individuality to each piece.

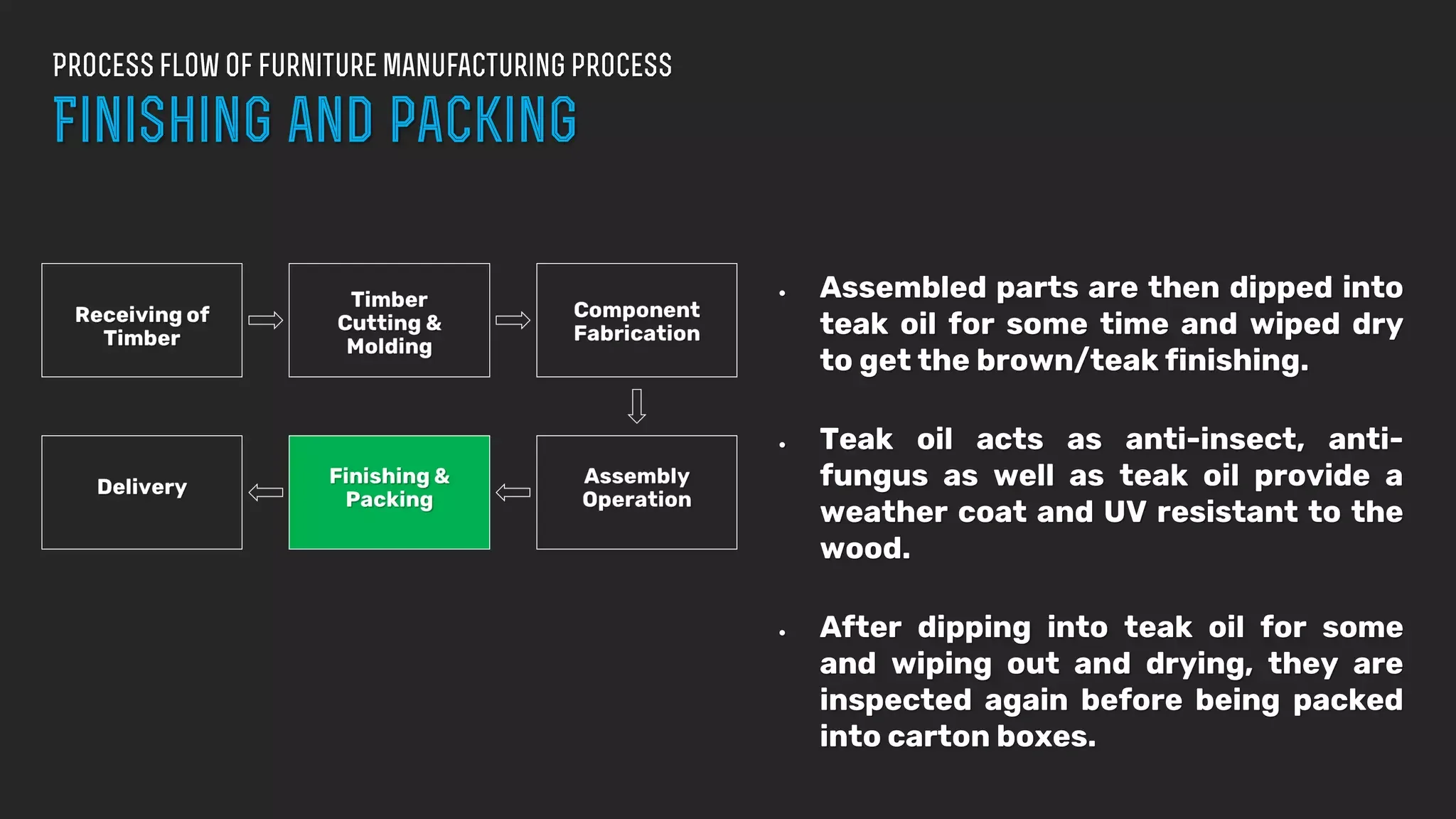

7. Adding the Final Touches

After installation, the furniture undergoes a finishing procedure that includes sanding, staining, and polishing. These techniques improve the wood’s natural magnificence, delivering a range of options, from a natural wood finish that emphasizes the grain to dynamic colors that complete the overall design.

8. Upholstery and Fabric Selection

For pieces needing upholstery, craftsmen usually select dynamic and intricately patterned fabrics. Fabrics like silk, cotton, and yarn are carefully picked to complete the overall design and style.

9. Quality Assurance

Quality control is significant in the manufacturing process. Each piece is comprehensively checked for imperfections, guaranteeing that it satisfies the high pinnacles of Indian craftsmanship. Any essential adjustments or restorations are created to ensure the furniture’s quality and longevity.

10. Packaging and Shipping

Once the furniture passes quality control, it is excellently packaged to resist the severities of transportation. Indian furniture is shipped worldwide, making appropriate packaging necessary to prevent damage. Shipping methods differ, with some pieces sent by sea or air to reach customers across the globe.

The Authenticity of Indian Furniture

Indian furniture is not just practical; it’s a testimony to prosperous cultural roots. Each table, chair, or cabinet represents

the traditions and craftsmanship that have been perfected over centuries.

The artisans, often operating within small family-owned workshops, pour their hearts and souls into every work they do. Their dedication to maintaining the art of hand craftsmanship is not just witnessed but also handled in the final outcome.

Above its functional utility, Indian furniture has inherent significance. It relates the story of a country that loves its roots,

honors diversity, and appreciates the artistry of its people.

Indian furniture manufacturing is a world of professional artisans and prosperous practices. It all starts with carefully chosen materials and ends with the design of practical yet beautifully crafted pieces. In this blog, we’ll bring you on a journey through the manufacturing process of Indian furniture, emphasizing the processes, materials, and complex elements that make it outstanding. So, let’s get started. Indian Furniture Manufacturing Process

1. Selecting the Right Materials

The journey begins with a brilliant choice of wood. Different types of wood, like Sheesham (Indian Rosewood), Teak, Mango, and Acacia, are selected for their durability and grain patterns. The selection of wood lays the foundation for the furniture’s quality and appearance.

2. Seasoning the Wood

Before any carving or cutting starts, the selected wood undergoes a critical procedure known as seasoning. Seasoning involves lowering the wood’s moisture content to deter warping or breaking in the final product. Traditional methods of seasoning include air drying and kiln drying.

3. Design and Planning

The heart of Indian furniture lies in its complex structures. Skilled craftsmen specifically plan the furniture’s measurements, joints, and carving designs. These designs often attract inspiration from regional aesthetics and cultural motifs, resulting in a range of styles, from elaborate Mughal results to simpler, rustic designs.Visit for More:- wood counter design

4. Hand-Crafted Precision

Hand craftsmanship is the heart of Indian furniture production. Skillful craftspeople employ traditional tools like chisels, saws, and hand planes to engrave, build, and complete each piece. It’s the artisan’s expertise that takes out the attractiveness of complex carvings, inlay work, and joinery techniques, providing Indian furniture its unique personality.

5. Joinery Techniques

The stability and longevity of the furniture rely on different joinery techniques. Mortise and tenon joints, dovetail joints, and

tongue-and-groove joints are excellently utilized to make sturdy and long-lasting pieces.

6. Inlay and Marquetry

One of the most exquisite parts of Indian furniture is the stunning inlay and marquetry creation. Artisans use materials like

bone, mother of pearl, and nerve to craft complex patterns and designs on the furniture’s character. This labor-intensive process adds luxury and individuality to each piece.

7. Adding the Final Touches

After installation, the furniture undergoes a finishing procedure that includes sanding, staining, and polishing. These techniques improve the wood’s natural magnificence, delivering a range of options, from a natural wood finish that emphasizes the grain to dynamic colors that complete the overall design.

8. Upholstery and Fabric Selection

For pieces needing upholstery, craftsmen usually select dynamic and intricately patterned fabrics. Fabrics like silk, cotton, and yarn are carefully picked to complete the overall design and style.

9. Quality Assurance

Quality control is significant in the manufacturing process. Each piece is comprehensively checked for imperfections, guaranteeing that it satisfies the high pinnacles of Indian craftsmanship. Any essential adjustments or restorations are created to ensure the furniture’s quality and longevity.

10. Packaging and Shipping

Once the furniture passes quality control, it is excellently packaged to resist the severities of transportation. Indian furniture is shipped worldwide, making appropriate packaging necessary to prevent damage. Shipping methods differ, with some pieces sent by sea or air to reach customers across the globe.

The Authenticity of Indian Furniture

Indian furniture is not just practical; it’s a testimony to prosperous cultural roots. Each table, chair, or cabinet represents

the traditions and craftsmanship that have been perfected over centuries.

The artisans, often operating within small family-owned workshops, pour their hearts and souls into every work they do. Their dedication to maintaining the art of hand craftsmanship is not just witnessed but also handled in the final outcome.

Above its functional utility, Indian furniture has inherent significance. It relates the story of a country that loves its roots,

honors diversity, and appreciates the artistry of its people.

We have divided our infrastructure into following mentioned department

1. Commercial Offices 2. Conference Room 3. 3d A New Way Of Imagination 4. R&D Department And Sample Room 5. Barcode & Label Department 6. Quality Control Office 7. Packing Halls 8. Color Plant 9. Polishing Halls | 10. Powder Coating Plant 11. Electro Plating Plant 12. Safety And Facilities Of Factory 13. Warehouse Double Story 14. Container Loading Area 15. Pallet & Slip Sheet Packaging 16. Raw Goods Storage Area 17. Inhouse Manufacturing Department 18. Factory Showroom |

Why Choose Us

AN EXPERIENCE - NOT A TRANSACTION

QUALITY MATERIALS

VINTAGE CRAFTSMANSHIP

FAMILY OWNED SMALL BUSINESS

Trade Show Photo

Product packaging

We have a qualified packaging quality team in our factory who provide packaging formulas as per the products considering the risk , transit etc. We do normal coorogated box packaging, 4 color box packaging, mail order packaging, display box packaging, PDQ box packaging, wooden and corrugated pallet packaging, slip sheet packaging etc.

Bubble Wrap & Corrugated Paper Packaging

Product will be packed inside foam, corrugated box & 70 GSM bubble sheet. Corners will be covered with foam. Then strip will be placed on product in order to make packaging stronger. Stickers and markings will be added as per requirement.

Double Corrugated Paper Packaging

Product will be packed inside foam & double corrugated box. Corners will be covered with foam. Then strip will be placed on product in order to make packaging stronger. Stickers and markings will be added as per requirement.

Carton Packaging

Product will be packed into foam & corners will be covered with foam. This will then be placed inside a master carton. Stickers and markings will be added as per requirement