Wet Dry Laboratory Cylindrical Rod Mill 50kg/h Small Ball Mill Rock Gold Ore Grinding

US $960.00-1,000.00 / unit

1 unit(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

50 Set/Sets per Month

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 50 Set/Sets per Month |

| Place of Origin | HENAN |

| Brand Name | ROCKWEEL |

| Dimension(L*W*H) | Customized |

| Weight | 800 KG |

| Warranty | 1 years |

| Model Number | 400x600 |

| Gear Material | 45# steel |

| Feed particle size | ≤20mm |

| Ball loading capacity | 1.0-1.2t |

| Discharge particle size | 0-2mm |

| Processing capacity | 50kg/h |

| Motor power | 6 stages 2.2kw |

| Reduce | ZD25 |

| Liner | manganese steel 30*50mm |

| Cylinder thickness | 10mm |

| Applicable Industries | hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Showroom Location | Egypt, United States, Germany, Brazil, Peru, Saudi Arabia, India, Mexico, Spain, Morocco, Argentina, South Korea, UAE, Colombia, Sri Lanka, Ukraine, Tajikistan, Japan, Malaysia |

| Warranty of core components | 1 Year |

| Condition | New |

| Marketing Type | Hot Product 2024 |

Product Detail

Product Detailes

400x600 ball mill

The 400x600 ball mill has a feed size of 20mm, a discharge size of 0.075-0.89mm, a ball loading capacity of 50kg/h, an output of about 0.5 tons per hour and a motor power of 2.2kw.

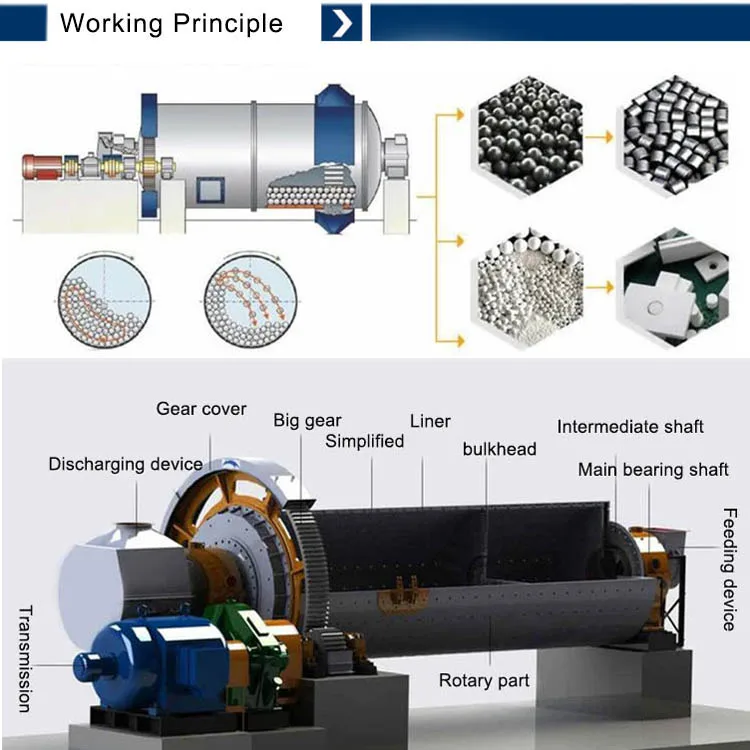

Energy-saving ball mill equipment consists of feeding part, discharging part, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The hollow shaft is made of cast steel with removable inner lining, the big gear of rotary adopts casting hobbing processing, and the cylinder body is embedded with wear-resistant lining plate, which has good abrasion resistance. The machine runs smoothly and works reliably.

Product paramenters

400x600 Ball bill | ||

Model | 400x600 | |

Gear material | 45# steel | |

Feeding size | ≤20mm | |

Ball loading capacity | 1.0-1.2t | |

Discharge size | 0-2mm | |

Processing capacity | 50kg/h | |

Motor power | 2.2kw | |

Lining plate | manganese steel 30*50mm | |

Thickness of cylinder | 10mm | |

Weight | 800kg | |

Production Structure

How it works:

Wet energy-saving lattice-type ball mill is a small diameter and length of the main components of the cylinder, through the transmission device to make it rotate slowly, the material from the cylinder feeding end into the cylinder due to the steel ball and the ore itself, the impact of the fall and self-grinding, the material can be crushed. Due to the continuous feeding of materials, the pressure prompts the materials in the cylinder to move from the feeding end to the discharging end. The material that reaches the finished size is discharged from the discharge end of the cylinder. When wet grinding, the material is carried out by water flow; when dry grinding, the material is carried out by air flow. Energy-saving ball mill equipment at the discharge end of the discharge lattice, the mill relies on the lattice plate to force the discharge of the ore, the slurry surface in the cylinder is low, reduce the overgrinding of the ore, and prevent the discharge of steel balls. Under the same production conditions, the production capacity is higher than the overflow type mill. Rolling bearings are used at both ends of the cylinder instead of sliding bearings, which saves energy significantly.

Product packaging

Product Show

Company Profile

Henan Rockwell Machinery Co., Ltd.

Henan Rockwell Machinery Co., Ltd. is a large-scale joint-stock enterprise which mainly produces heavy mining equipment and integrates scientific research, production and sales. The company is located in No.1 High-end Machinery and Equipment Industrial Park in Gongyi City, Henan Province, covering an area of 20,000 square meters, with 15,000 square meters of standardized heavy industrial manufacturers, and all kinds of large and medium-sized gold processing, riveting and welding, assembly equipment.

Our company is a domestic production plant mainly producing crusher equipment, sand making machine equipment, grinding equipment, gold processing equipment, building materials equipment and so on. The main products are: crusher, sand making machine, brick making machine, grinding mill, gold mill, ball mill, gold processing equipment and so on.

Our company strives for survival by quality and follows the responsibility system of each process and each piece of equipment, so that friends from all over the world can buy good equipment at the wholesale price of manufacturers. Sincerely welcome you to come to our factory for field inspection and purchase!

Why Choose Us

1、How to buy equipment from our factory?

First of all, you need to according to your own needs, such as what is the maximum particle size of the rock you need to grind? How many tons per hour? The location of the power is sufficient to determine the model of the ball mill you need, and then through the packaging size and weight of the equipment to determine the freight cost, everything is determined before placing an order.

2、How does the factory ship after payment?

After we receive your deposit, we will produce according to the requirements, after the completion of production for the factory test machine, you see the effect of the test machine, if you are satisfied, pay the final payment, we carry out packaging and shipment.

3、What if I don't know how to install the machine after receiving the goods?

Small ball mill arrives at the user's site, you only need to connect the electricity can be produced, medium-sized ball mill needs to be divided into containers, we will send you the installation video, if you do not know how to operate according to the video, you can make a remote video, manufacturers one-on-one video guidance, large ball with the garden food machine can be arranged for overseas personnel on-site guidance for installation.

4、How to solve the problems in the use of ball mill?

Ball mill in the use of the process of regular maintenance and maintenance, if improper maintenance caused by damage, need to replace the wearing parts in time, we will send the operation video, if you still do not know how to operate, we can remote video, one-on-one guidance operation. If non-human damage, equipment problems, our factory is responsible for free delivery of wearing parts.

5、How to protect the equipment you purchased?

Our factory for one-on-one manual service, pre-sale, sale, after-sale will be tracking service, we are manufacturers, can provide a variety of technical support, to protect your purchase of equipment with peace of mind, with the comfort.