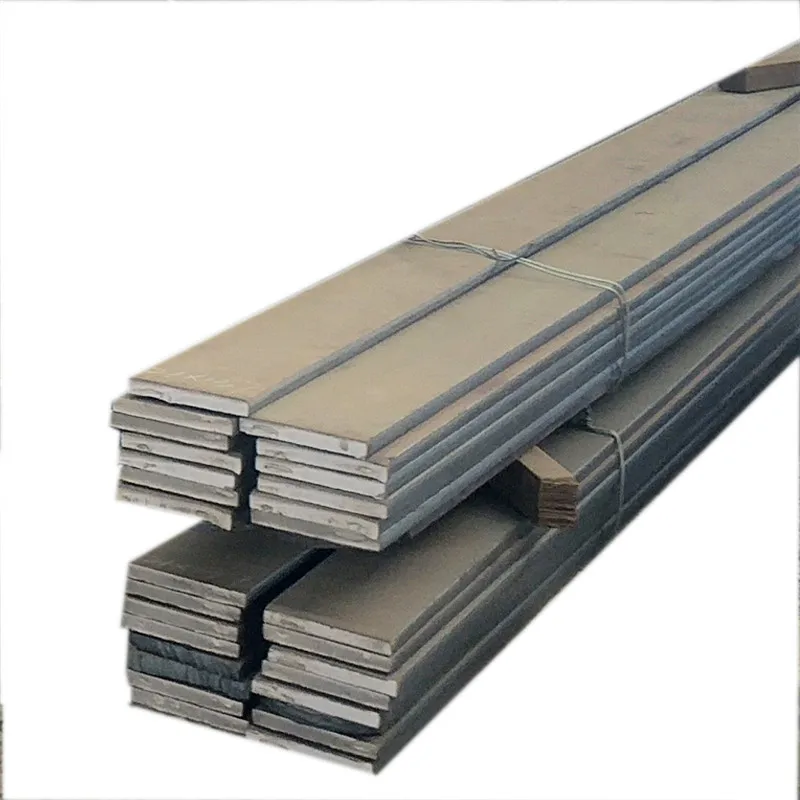

Wholesale High Quality SUS304 Ss Flat bar Stainless Steel 316 Flat bar and Ss316 Flat Steel

US $560.00-587.00 / ton

1 ton(s)Minimum order

Standard:

AiSi

Grade:

Q235,Q345,304 stainless steel, 316 stainless steel

Width:

220~2500MM

Length:

Customized Length

Place of Origin:

Shandong, China

Brand Name:

HeFa

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Standard | AiSi |

|---|---|

| Grade | Q235,Q345,304 stainless steel, 316 stainless steel |

| Width | 220~2500MM |

| Length | Customized Length |

| Place of Origin | Shandong, China |

| Brand Name | HeFa |

| Application | Construction, machine building, etc |

| Technique | Hot Rolled |

| Special Use | Mold Steel |

| Tolerance | ±1% |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting |

| Alloy Or Not | Is Alloy |

| Delivery Time | 8-14 days |

| Product name | Flat Steel Bar |

| Surface | Mild Steel Plain |

| Anti Corrosion Treatment Method: | Hot dip galvanizing, spraying, chemical treatment |

| Certificate | CE |

| Advantage | Anti-Corrosion, Fire Resistant, Durable, water resistant |

| Shape | Equilateral Angle Bar |

| MOQ | 1 Ton |

| Package | Waterproof Paper + Woodern Case |

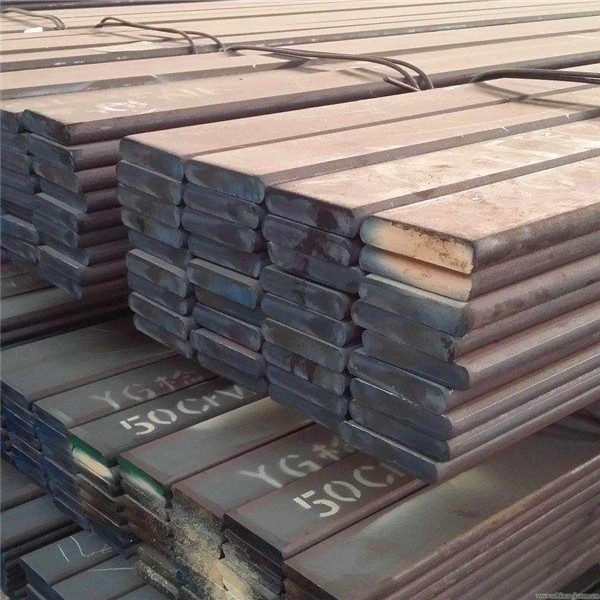

Product Detail

FACTORY DISPLAY

Main advantages:

1. Easy to process: The flat cross-section and uniform thickness make it very suitable for cutting, welding, and processing,The processing technology is simple and can easily produce components of different shapes and sizes.

2. High load-bearing capacity: The cross-sectional design is relatively simple, but it has a high bearing capacity, especially in applications where the force direction is relatively uniform. Flat steel can effectively disperse the force and withstand large loads.

3. Strong corrosion resistance: During the production process, anti-corrosion treatment such as hot-dip galvanizing or spraying can be carried out according to the needs, which is suitable for environments that require high anti-corrosion requirements and increases the service life of materials.

PRODUCT PARAMETERS

Product Name: | Flat Steel |

Common Specifications: | 20×3 mm、50×5 mm、80×6 mm、100×10 mm、120×12 mm |

Material: | Q235,Q345,304 stainless steel, 316 stainless steel |

Anti Corrosion Treatment Method: | Hot dip galvanizing, spraying, chemical treatment |

Application | Construction,Equipment,Industry, Decoration, etc., Boiler,Pressure vessel, |

Specification | Width (b) | Thickness (t) | Unit Weight (kg/m) |

20×3 | 20 mm | 3 mm | 0.75 kg/m |

30×5 | 30 mm | 5 mm | 1.20 kg/m |

50×5 | 50 mm | 5 mm | 2.00 kg/m |

80×6 | 80 mm | 6 mm | 4.00 kg/m |

100×10 | 100 mm | 10 mm | 7.50 kg/m |

120×12 | 120 mm | 12 mm | 11.50 kg/m |

150×15 | 150 mm | 15 mm | 18.50 kg/m |

COMPANY PROFILE

Shandong Hefa Steel Co., Ltd. Is a Large-Scale International Steel Production and Sales Enterprise Integrating Production, Sales, Processing, Distribution and Service.

The Company Built a Factory in 2012, Covering an Area of 50,000 Square Meters. There Are 360 Employees, Including 5 Senior Engineers, 10 Engineers and 40 Professional and Technical Personnel. 14 Steel Production Lines, 10 Processing Equipment, Processing, Bending, Painting, Heat Treatment, Cutting, Drilling, Groove, Tempering, Surface Treatment, Etc. Testing Equipment Is Complete, Strong Technical Force. Annual Production Capacity of More Than 60,000 Tons.

The Company Has Passed the Iso9001 International Quality Management System Certification, And Has Obtained Provincial Enterprise Credit Certificate, Enterprise Credit Certificate, Quality Service Certificate, Integrity Management Demonstration Unit and Other 8 Quality System Certification Certificates.

The Main Products of the Company: Steel Bar, Stainless Steel, Aluminum, Carbon Steel, Alloy Steel, Plate, Profile, Pipe and so On.

The Company Has Established Perennial Cooperative Relations with Chengdu Iron and Steel Group, Metallurgical Steel Group, Baotou Steel Group, Baosteel Group, Angang Steel Group, Tianjin Seamless, Northeast Special Steel, And Other Well-Known Domestic Major Steel Mills. Applicable to Petroleum, Chemical, Electric Power, Metallurgy, City Gas, Heat Pipe Network, Ships and Other Industries.

The Company's Business Philosophy: "The Same Product Than Quality, The Same Quality Than Price, The Same Price Than Service, The Same Service Than Reputation."

Our customers

PACKAGING AND TRANSPORTATION

FAQ

1.What are the welding precautions for flat steel?

(1) Preheating treatment: For thicker flat steel, especially high-strength steel, preheating should be carried out before welding to avoid cracks caused by excessive temperature differences.

(2) Selection of welding materials: Choose appropriate welding materials based on the material of the flat steel to ensure the strength of the welded joint.

(3) Welding sequence: The welding sequence should be controlled to avoid excessive thermal stress during the welding process, which can cause deformation of the flat steel.

2.How to evaluate the fatigue strength of flat steel?

The fatigue strength of flat steel usually depends on its material properties and the alternating loads it is subjected to. The fatigue strength can be evaluated by using the S-N curve (stress life curve) during design. The conventional fatigue strength assessment methods include:

(1) Load amplitude: Calculate the fatigue life based on the amplitude and frequency of alternating loads in the working environment.

(2) Fatigue resistance of materials: Select a suitable fatigue strength calculation method based on the material of the flat steel to predict its fatigue life.

3.What are the anti-corrosion treatment methods for flat steel?

The anti-corrosion treatment methods for flat steel include:

(1) Hot dip galvanizing: immersing flat steel in molten zinc to form a layer of zinc coating to prevent corrosion.

(2) Spray coating: Use epoxy resin, polyurethane and other coatings to spray the surface of flat steel to enhance its anti-corrosion performance.

(3) Chemical treatment: Surface treatment through chemical processes to form an anti-corrosion film.