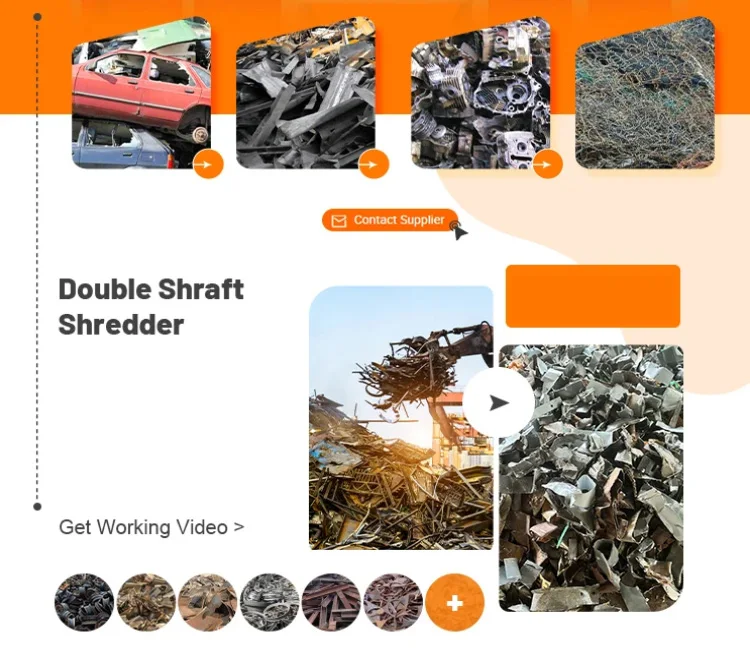

Wide Range of Applications Used Scrap Metal Shredder Aluminium Engine Blocks Car Shell Rebar Organic Metal Shredder in China

Other recommendations for your business

Contact us

Quik Detail

| place of origin | Henan, China |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| core components | PLC, Engine, Bearing, Gearbox, motor, Pressure vessel, Gear, Pump |

| brand name | Customizable |

| warranty | 1 Year |

| material / metal processed | Stainless Steel, Brass / Copper, Alloy, Carbon steel, Aluminum, All scrap metal |

| power (kw) | 55 |

| weight (kg) | 7500 |

| key selling points | Long Service Life |

| Name | Metal Shredder |

| Keyword | Various Scrap Metal Crusher Aluminum and Stainless Steel Crusher |

| Color | Customizable |

| Application | Crushing scrap metal, aluminum, plastics, steel and all other metals |

| Function | Recovery and reuse of scrap metal and other materials |

| Crushing material | Scrap metal, plastic, rubber, wood, tires and other waste. |

| Final product | 1-10cm metal scraps |

| Advantage | High Efficiency Low Energy |

| Suit for | Waste recycling and reuse |

| Raw material | All scrap metal, wood, plastic, rubber, tires and other waste |

| Condition | New |

| Warranty of core components | 1 Year |

| Applicable Industries | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Retail, Construction works , Energy & Mining, Other |

| Showroom Location | None |

| Marketing Type | 2024 Best Selling New Product |

Product Detail

kind of coarse shredder, through shearing, tearing and extrusion to achieve the reduction of material size, used to deal with raw materials or Leftover material. The equipment adopts PLC automatic control system, with start, stop, reverse and overload automatic reverse control function, with low rotational speed, high torque, low noise and other characteristics.

Model | Blade diameter | Spindle diameter (mm) | Reducer model | Motor | L*W*H(mm) | |||||

600 | 220mm | 110mm | ZQ400*2 | 11kw*2 | 2500*1100*1600 | |||||

800 | 260mm | 130mm | ZQ500*2 | 18.5kw*2 | 3000*1400*1800 | |||||

800 | 300mm | 140mm | ZQ650*2 | 30kw*2 | 3600*1700*2100 | |||||

800 | 400mm | 180mm | ZQ650*2 | 30kw*2 | 3600*1700*2200 | |||||

800 | 400mm | 180mm | Square box 650*2 | 30kw*2 | 3700*1700*2200 | |||||

800 | 400mm | 180mm | Square box 750*2 | 37kw*2 | 3700*1800*2200 | |||||

1000 | 400mm | 180mm | Square box 750*2 | 37kw*2 | 3900*1800*2200 | |||||

1200 | 400mm | 180mm | Square box 750*2 | 45kw*2 | 4100*1800*2300 | |||||

1400 | 500mm | 260mm | Square box 850*2 | 55kw*2 | 4700*2100*2400 | |||||

1600 | 500mm | 260mm | Square box 1000*2 | 75kw*2 | 5400*2400*2600 | |||||

1800 | 600mm | 280mm | ZSY500*2 | 90kw*2 | 5600*2400*2800 | |||||

2000 | 650mm | 320mm | GX2KAH17*2 | 132kw*2 | 2660x1360x800 | |||||

multinational corporations by the customer's unanimous praise.(At the same time can be customized according to customer requirements to drawings and samples of non-standard products)

Outer packing: usually wooden case or container, we can also pack the machine according to customer's requirement.

We will customise according to customers' actual requirements. Senior designers start to design the programme. After receiving the deposit, we will finish the delivery within 10 to 15 working days.

A:Our factory established from 2004, and most of our engineers are workingin this industry over 20 years.

Q:Can you customise the product for me?

A:Yes. We can customize according to customer's requirements in terms of model, knife type, colour, etc. Meanwhile, our engineers can also give you professional guidance advice.

Q:Do you provide after-sales service?

A:Yes. Our machine warranty is one year. We have professional after-sales service team to solve your problem within 24 hours.

Q:What are the payment terms?

A:40% down payment as deposit and 60% balance before shipment.