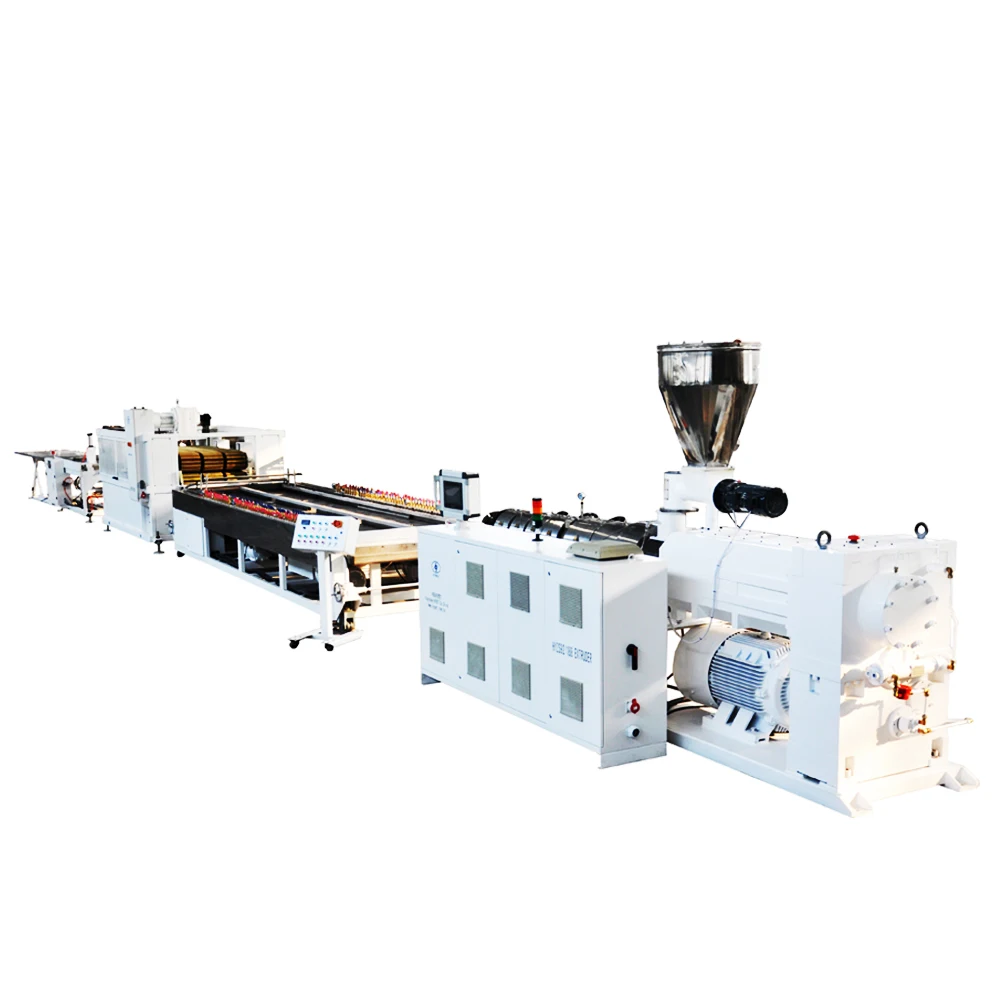

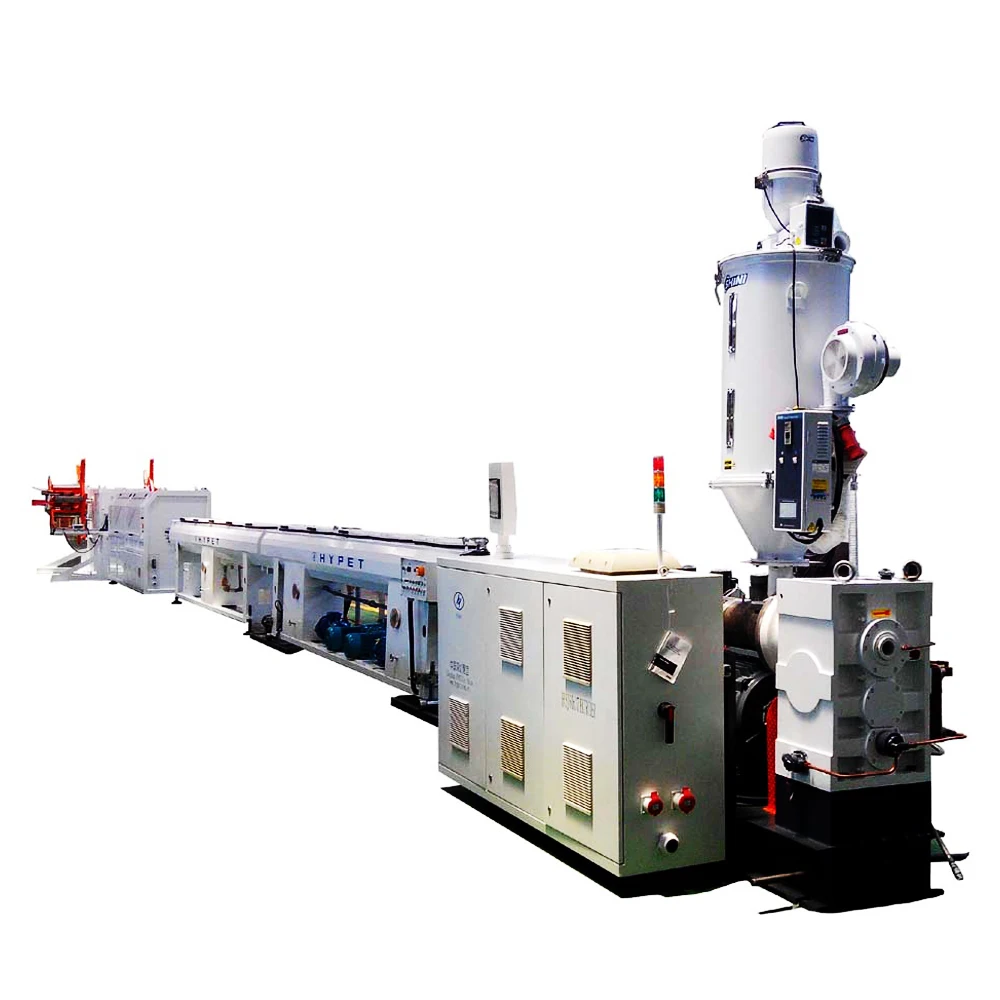

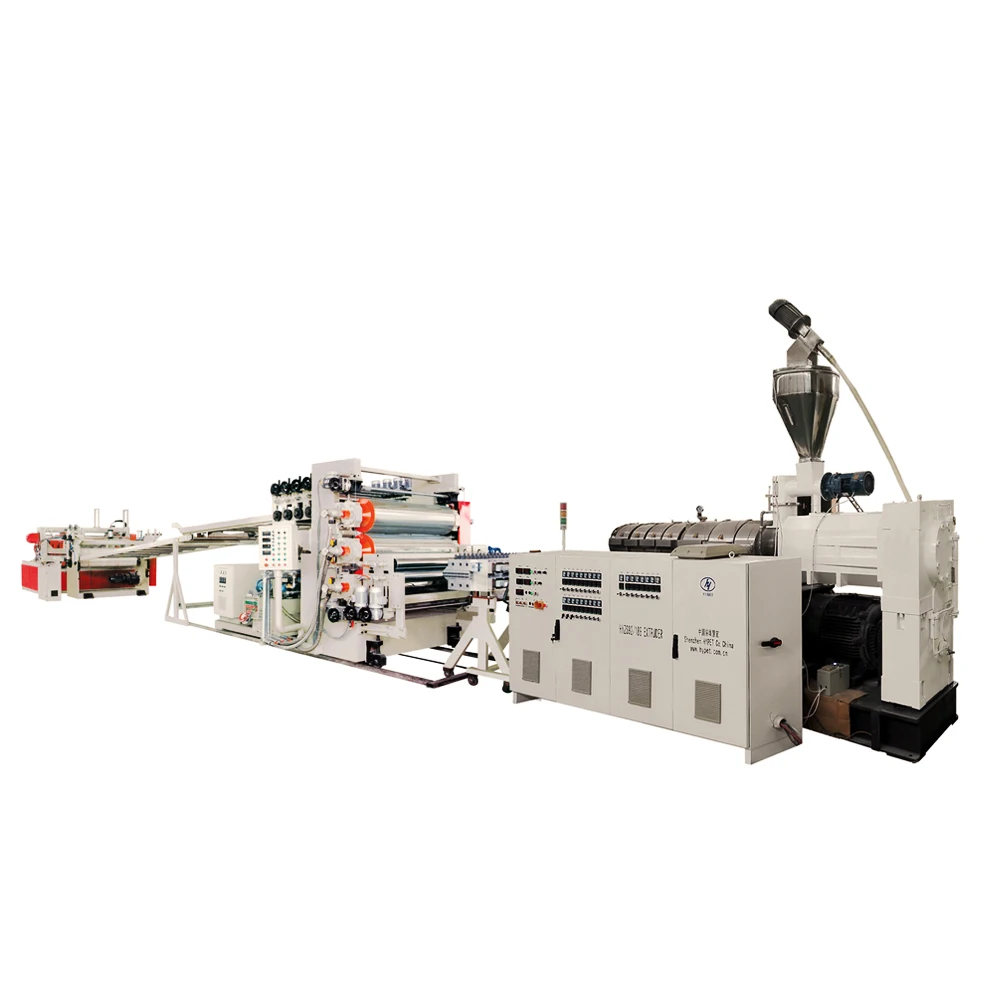

WPC Door Production Line/ PVC Wood and Plastic Composite Door Panel Production Making Machine /WPC Profile Extrusion

US $30,370.00 / set

1 set(s)Minimum order

plastic processed:

PVC, WPC

application:

Profile

Screw Design:

Double-screw

twin screw type:

Counter-rotating conical Twin-screw

Screw Material:

38CrMoALA

screw l/d ratio:

28:1

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| plastic processed | PVC, WPC |

|---|---|

| application | Profile |

| Screw Design | Double-screw |

| twin screw type | Counter-rotating conical Twin-screw |

| Screw Material | 38CrMoALA |

| screw l/d ratio | 28:1 |

| Screw Speed (rpm) | 48 rpm |

| place of origin | Hubei, China |

| brand name | HYMAX |

| voltage | 380V 50Hz 3Phase or customized |

| warranty | 1 Year |

| key selling points | Energy saving |

| video outgoing-inspection | Provided |

| core components | motor, Pump, PLC, Gearbox, Screw |

| machinery test report | Provided |

| Keywords | WPC door production line |

| Final product | Door panel |

| Cavities | Single/double/four |

| Extruder model | ZS45/51/55/65/80/92 |

| Extruder type | Conic twin screw extruder |

| Control system | PLC with touch screen |

| Motor/Inverter | Siemens/ABB/China top brand |

| Processing material | PVC Composite powder |

| Certification | ISO9001, CE |

| Engineer installation service | Yes |

| Condition | New |

| Showroom Location | Egypt, Turkey, Pakistan, India, Kenya, Argentina, Algeria |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops |

| Warranty of core components | 1.5 years |

| Weight | 15000 KG |

Product Detail

Product Description

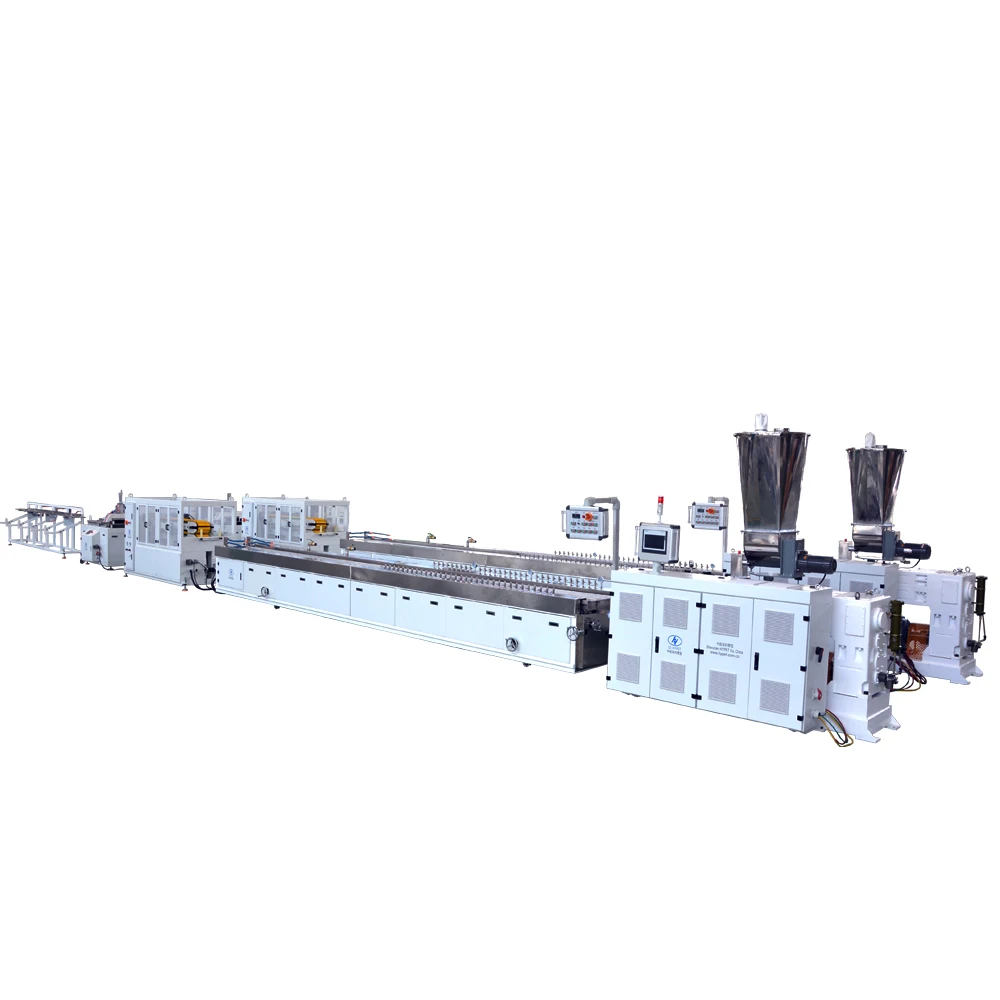

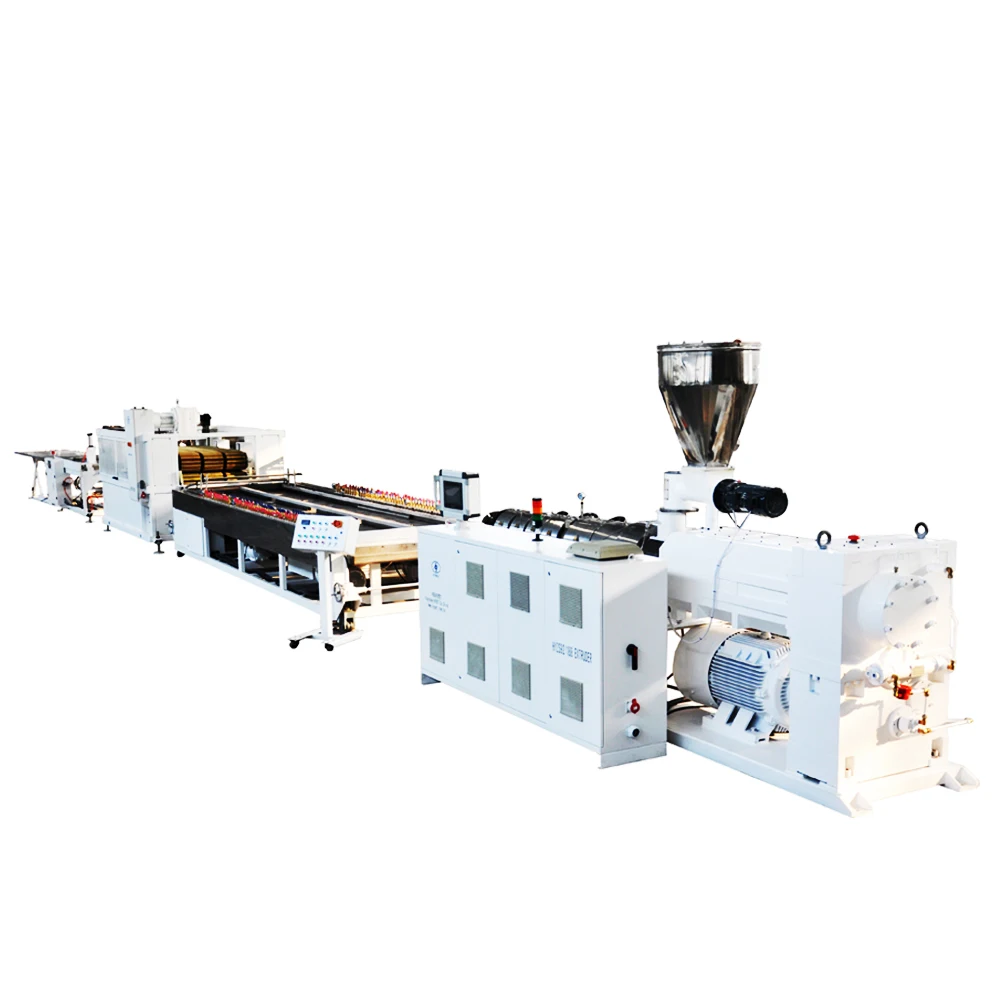

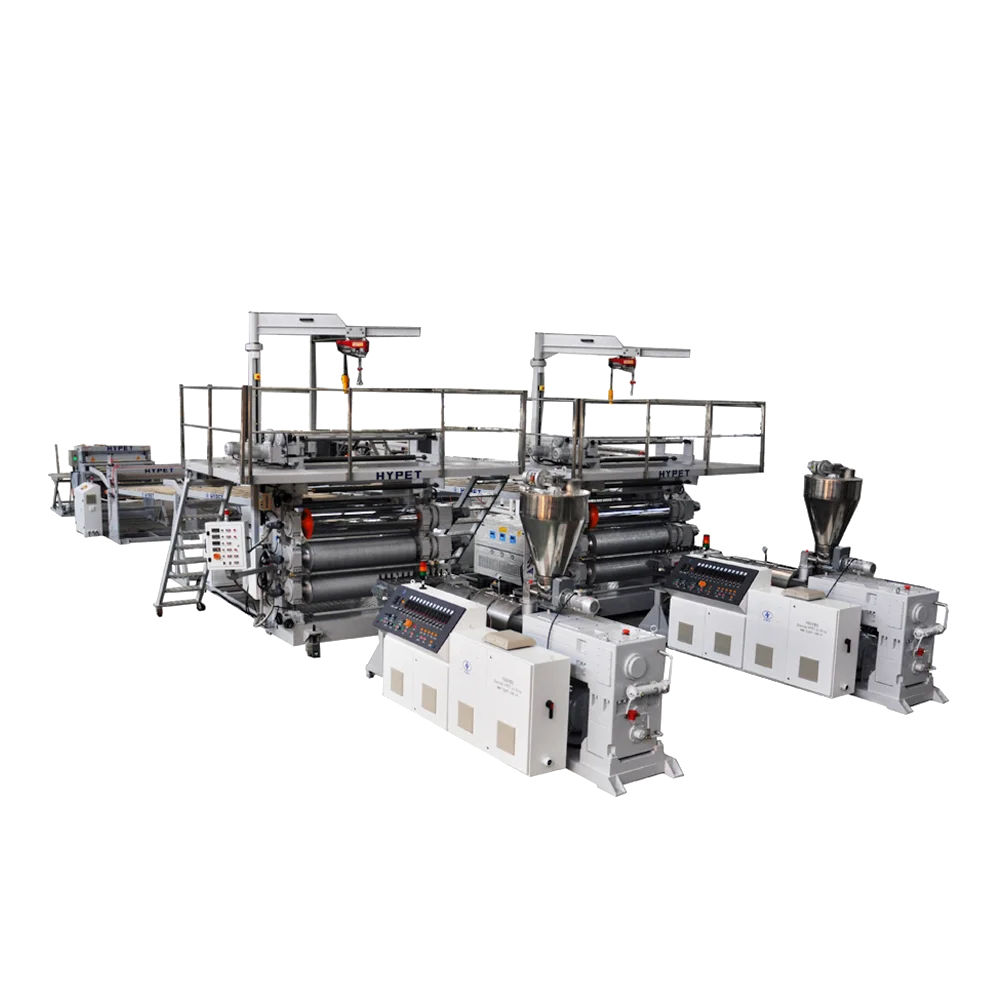

PVC-WPC DOOR PRODUCTION LINE

1. High output: Ensure you the highest output as compared with other supplier.

2. New technology gear box: High torque gear box, one body design, two cooling system.

3. Screw and barrel: Bi-metal material ensure longer working life, ensuring running non-stop 24 hours /day.

4. Energy saving heater: Heater on the barrel is energy saving type by 15%.

5. Electric elements and box: In detachable, with world famous brand such ABB, Siemens, Schneider, Delta, well organized.

6. HYPET PLC control system: With operation easy, management full, energy saving and counting, and intelligent control system.

7. Pipe brighten device: To make the pipe shining and smoothing.

8. Vacuum tank stainless steel 304: Water level and temperature controlled automatically.

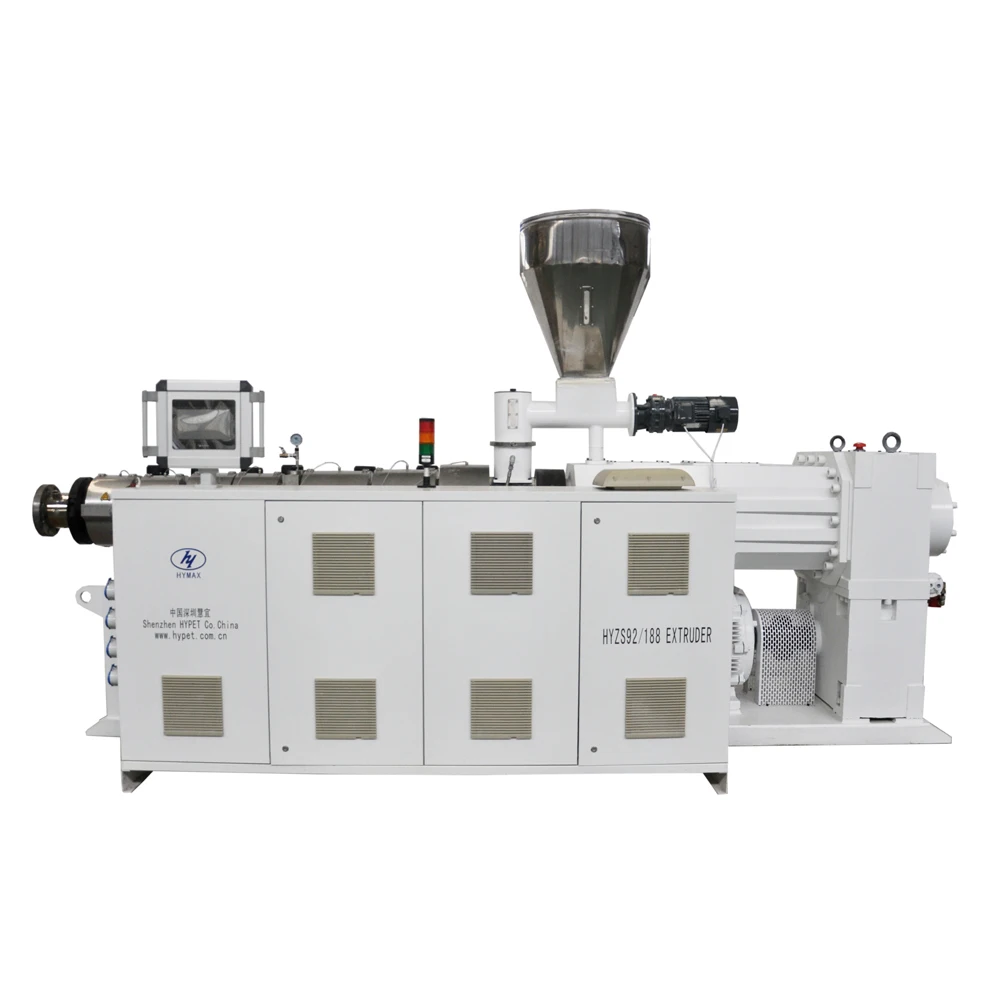

Conic Twin Screw Extruders

High output / High torque /High quality

Self owned gear box patent

Self designed screw

Dual cooling system

Anti blocking feeder

Super size touch screen

Energy saving heaters

Low noisy blower

Top brand inverter

Strong motor

Twin conic screw extruder series | ||||||||||||||||||

Item | 35/80 | 45/100 | 51/110 | 55/120 | 65/132 | 80/156 | 80/173 | 92/188 | ||||||||||

Main motor | 7.5 | 15 | 18.5 | 30 | 37 | 45 | 55 | 75 | 110 | |||||||||

Output | 75 | 120 | 140 | 250 | 350 | 450 | 550 | 650 | 950 | |||||||||

Vacuum pump | 1.1kw | 1.5kw | 1.5kw | 1.5kw | 2.2kw | 2.2kw | 3kw | 3kw | 4kw | |||||||||

Price USD | 11500 | 13500 | 14500 | 16300 | 17500 | 18500 | 27500 | 3300 | 43500 | |||||||||

Operating Screen

Super size operating screen to keep operation easily and well

Control system

Top brand Siemens PLC control sytem as operating heart

Heaters & blowers

Energy saving type heaters and low noisy blowers

Feeder

Special anti blocking design

Frequency inverter

ABB or Heavy type Delta

Gear box

Own patent with two cooling

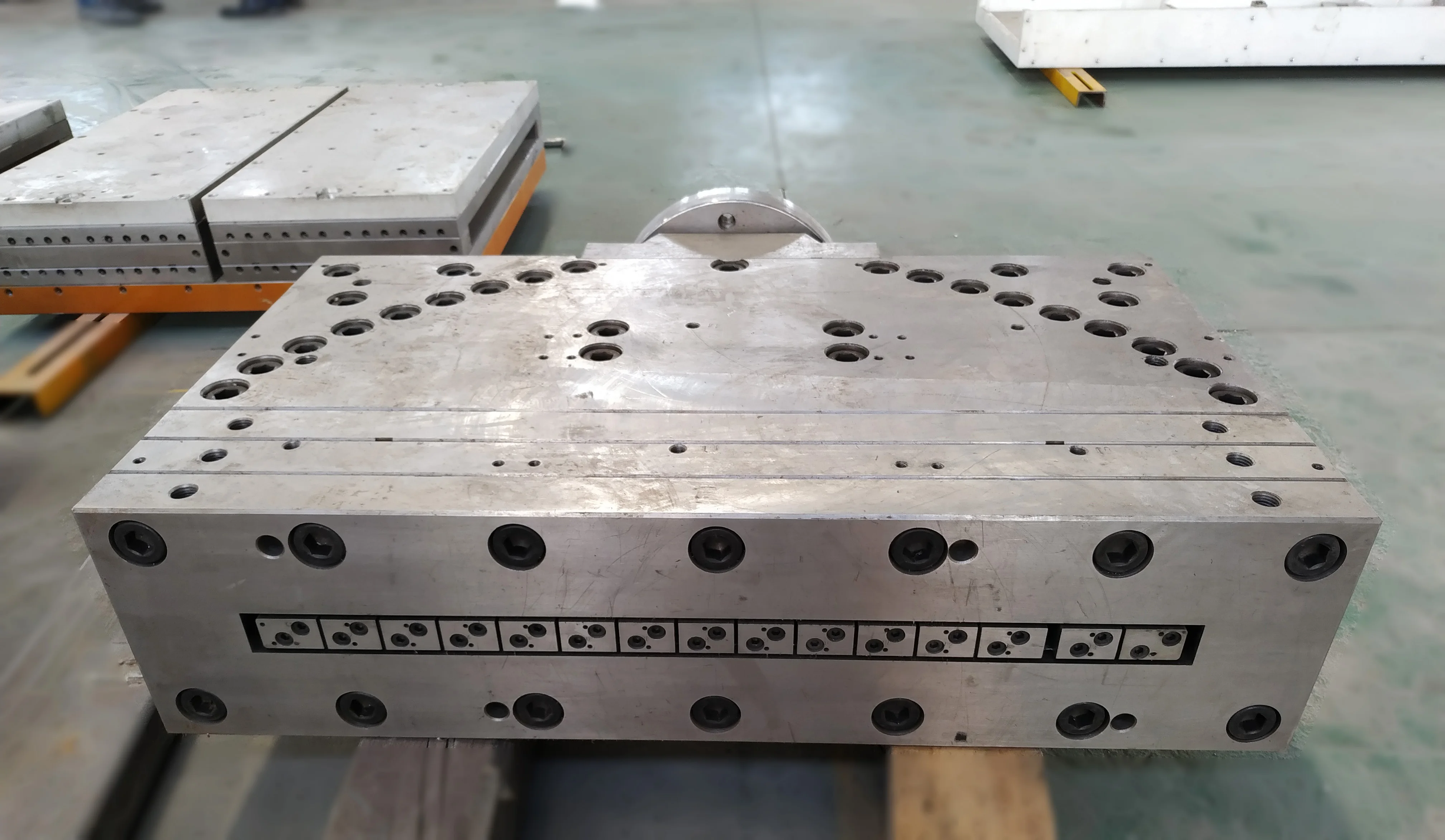

MOLDS

The pressure class and standard will be made according to the requirement.

Materials of construction, alloy steel with flow path hard chrome plated.

The flow path are milled and are highly polished.

Better material and design for longer time running and better surface.

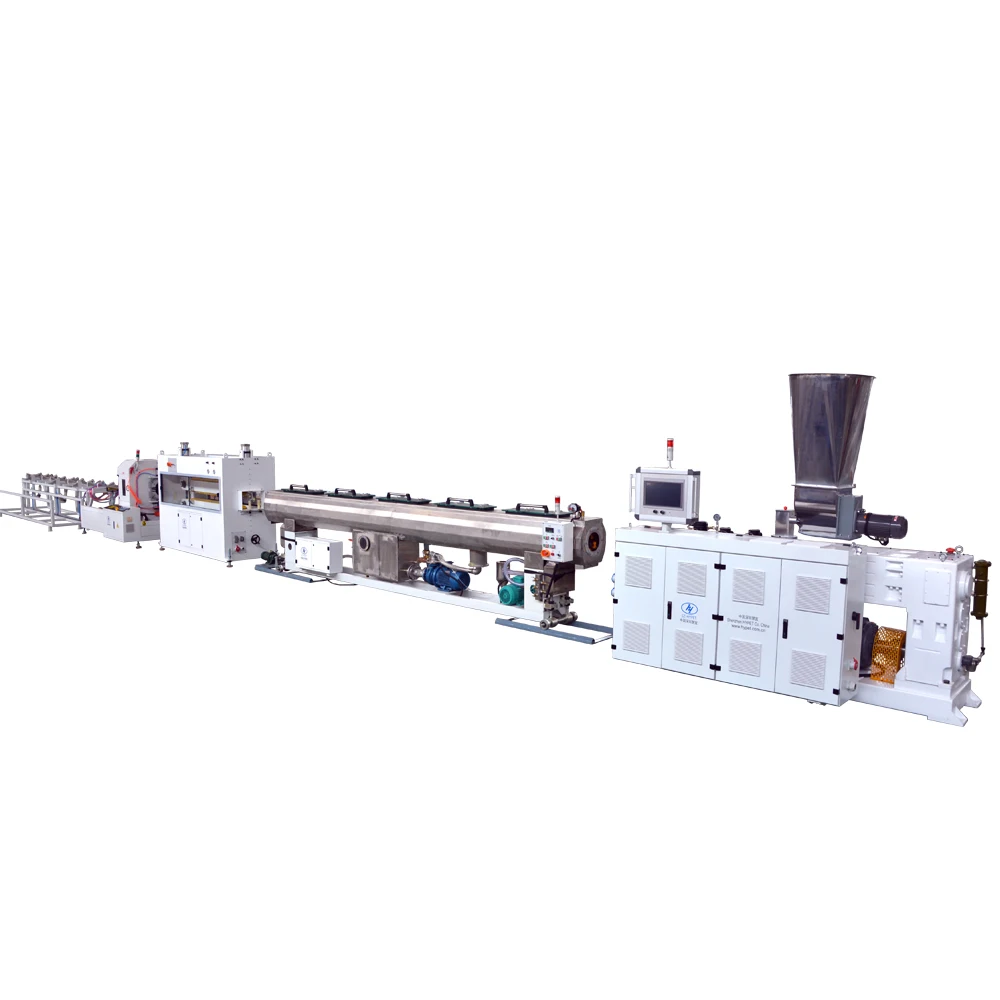

SHAPING TABLE

Vacuum Calibrator is with integrated leg & platform.

Screen water filter with bypass system, solenoid valve at entry & exit, float switch.

Visual inspection window is provided at the entry of the tank.

Height adjustment on wheels & Motorized longitudinal movement & manual cross adjustment.

HAUL OFF MACHINE

Consists of top and bottom support which houses chain driven jaws with V- rubber profile.

Bottom support is fixed one and top support is pneumatically operated by two sets of cylinders on either side.

Independent special characteristic Vector AC strong Geared motor for each traction.

CUTTER

Dustless cutter to save the material and Environmental protection

Cut neatly bright

No noise and energy saving.

Cast aluminum blocks for Clamping pipe

Carriage made of Aluminum is mounted on hardened and hard chrome plated guide bar with linear motion bearings.

STACKER

The tripping chute is made from MS rigid structural steel

Stainless Flat type Tilting table provided for smooth scratch less pipe moment.

Tilting table is Pneumatically operated

2 Nos. Limit switches with adjustable bracket provided to cut various pipe length

WPC door processing flow

1. Wood powder making

Nature wood--Crush into scrap--Mill to powder--Drying

2. Raw material mixing

All material (PVC, CaCo3, Wooden powder and chemical agents) Mixing and stock in material dryer

3. Panel Production

Make the big door panel in mold width and request length.

4. Precise cutting

Cutting the door in exactly request size

5. Polishing

Brush the surface to smooth.

6. CNC design

Carve different pattern on the door panel surface

7. Hot-stamp & Lamination & Painting

Three way to handle the panel surface for option. hot-stamping & Lamination &Painting.

8. Top & Bottom carving and seal

Carving a round hole and seal it with our suitable strip.

9. Packaging.

Package and ready for delivery.

Cooperative brands

Auxiliary machine for option

Puliverizer

Recycled scraps into powder

Mixer

Mixing PVC, filler, chemical agent

Crusher

Recycle the bad final product into scrap

Precise cutter

Cutting the door edge

Polishing machine

Brushing the door surface

Hotstamping machine

Door surface pattern film

CNC machine

Door pattern design

Door sealing machine

Sealing the top and bottom of door

Lamination machine

Door surface lamination

Wooden crusher

Recycle nature wood to scrap

Wooden miller

Making wood powder from scrap

Wooden dryer

Drying the wet wood powder

Series Lines & Data

No. | Profile range | Extruders | Main Motor | Output |

1 | 110 | 55/120 | 30 | 80-130 |

2 | 240 | 65-132 | 37 | 150-250 |

3 | 1000 | 92-188 | 110 | 350-450 |

Profile & Sheet production ine series | ||||||||||||

Final product | Width | Output | Extruder | Motor | Calibrator | Price | ||||||

PVC window and door profile | 240 | 350 | ZS65/132 | 45kw | 8m | 39010 | ||||||

PVC window and door profile | 180 | 160 | ZS55/120 | 30kw | 6m | 33430 | ||||||

PVC window and door profile | 110 | 120 | ZS51/110 | 22kw | 6m | 28570 | ||||||

PVC door panel | 1200 | 550 | ZS80/173 | 75kw | 8m | 69000 | ||||||

PVC-WPC door | 1000 | 600 | ZS92/188 | 110kw | 8m | 83980 | ||||||

PVC-WPC door frame | 240 | 250 | ZS65/132 | 37kw | 8m | 37040 | ||||||

PVC-WPC door cover | 120 | 160 | ZS51/110 | 22kw | 8m | 28570 | ||||||

Recommend Products

Company Profile

Certifications

Exhibition