YINGYONG Professional China Suppliers Cement Wet Type Sag Mill Rotary Sag Ball Mills/mill Price for Sale

US $5,500.00-8,050.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

PLC, Bearing, Gearbox, motor, Gear

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

50-100

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | PLC, Bearing, Gearbox, motor, Gear |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 50-100 |

| Place of Origin | Shanghai, China |

| Brand Name | YINGYONG |

| Dimension(L*W*H) | Customized |

| Weight | 50000 KG |

| Warranty | 1 Year |

| Product name | SAG Mill |

| Application | Iron, copper, limestone, gold, manganese, bauxite, lead-zinc ore |

| cylinder diameter(mm) | 4000-12200 |

| cylinder length(mm) | 1400-11000 |

| loading capacity(t) | 2-174 |

| rotating speed(r/min) | 9.2-16.2 |

| Power(kw) | 220-27000 |

| Quality | High Level |

| Price | Negotiable Resonable |

| Advantages | High Efficiency Low Energy |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Energy & Mining |

| Showroom Location | None |

| Marketing Type | Ordinary Product |

| Condition | New |

| Warranty of core components | 2 years |

Product Detail

Product Description

SAG Mill

The SAG mill also kown as medium-free grinding mill. The ore from the stope or the coarsely crushed ore can be directly fed into the mill. The biggest speciality of the SAG mill is that the crushing ratio is large, the input size of the grinding material is 300~400mm, sometimes even larger, and the output size can reach 0.1mm minimum, the crushing ratio can reach 3000~4000, and the inout size of ball mill is between 20-30mm, the output size is 0-3mm.

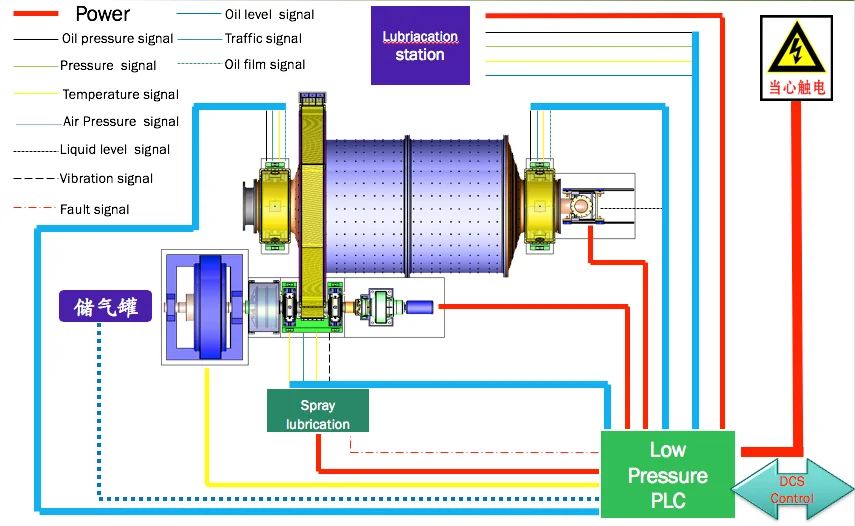

Working principle

The SAG mill is a new type of grinding equipment that combines both crushing and grinding functions. It uses the material itself as the medium to crush by mutual impact and grinding. The SAG mill has two kinds of dragging modes: variable speed and different power fixed speed. Some SAG mills are also equipped with micro-motion devices. In order to facilitate the maintenance, there is a

cylinder jacking device; for the large mill, in order to eliminate the static resistance torque at the start, a modern advanced technology such as a hydrostatic bearing is adopted to ensure the mill can operate safely.

The wet self-grinding system consists of a SAG mill, a particle size control operation, a secondary grinding equipment, and a hard-to-grain-level processing facility. Usually the mineral is fed into the mill bar at a certain ratio. The self-grinding machine can grind the material to 0.074mm at a time, and its content accounts for 20% to 50% of the total amount of the product. The crushing ratio can reach 4000~5000, which is ten times higher than the ball mill and rod mill.

cylinder jacking device; for the large mill, in order to eliminate the static resistance torque at the start, a modern advanced technology such as a hydrostatic bearing is adopted to ensure the mill can operate safely.

The wet self-grinding system consists of a SAG mill, a particle size control operation, a secondary grinding equipment, and a hard-to-grain-level processing facility. Usually the mineral is fed into the mill bar at a certain ratio. The self-grinding machine can grind the material to 0.074mm at a time, and its content accounts for 20% to 50% of the total amount of the product. The crushing ratio can reach 4000~5000, which is ten times higher than the ball mill and rod mill.

Type | Ball Mill |

Capacity(t/h) | Customized |

Dimension(L*W*H) | Customized |

Motor (kw) | 95-1250 |

price | negotiability |

advantage | high quality factory price |

Structural Features

▲ The end cap and the cylinder are not vertically connected, and the end cap liner is tapered;

▲ The drainage grid plate is added on the side of the discharge end, and the grinded material pass through the grid plate , then the cone cylinder sieve, material which cannot pass the seive is returned to the mill by the spiral self-return device, so closed grinding system is formed, which can further control the size of the product and reduce the amount of returning ore;

▲ Use a mobile feeder truck for the side mine;

▲ The girth gear is fixed on the hollow journal of the discharge end. The other part of the mill is constructed in much the same way as a dry SAG mill

▲ Use a mobile feeder truck for the side mine;

▲ The girth gear is fixed on the hollow journal of the discharge end. The other part of the mill is constructed in much the same way as a dry SAG mill

Drive types

Table 1 Basic parameters of wet self-grinding mill

Note :

1: The diameter of the cylinder refers to the inner diameter of the cylinder. The length of the cylinder refers to the length between the flange and the flange at both ends of the cylinder; the effective length is determined according to the size of the end liner and the grid; the effective volume refers to the cylinder, The volume of the end cap after removal of the liner, including the cone volume.

2: The ore particle size is <350mnu

3: The maximum ball loading is calculated as 3% of the effective volume.

4: The working speed is 75% of the critical speed. When the frequency conversion is adjusted, it will float up and down according to the rated speed of 10%~5%.

5: The models in brackets in common use

2: The ore particle size is <350mnu

3: The maximum ball loading is calculated as 3% of the effective volume.

4: The working speed is 75% of the critical speed. When the frequency conversion is adjusted, it will float up and down according to the rated speed of 10%~5%.

5: The models in brackets in common use

Case

Case 1

Project:

China Gold Group has signed an order contract for the largest dual-motor driven semi-autogenous mill and dual-motor driven overflow ball mill in China. The total designed power of the ball mill is currently the largest in the world. The equipment will be used in the Wunuuge Tushan Copper-Molybdenum Mine Project.

The designed capacity is 35,000 t /d, and the maximum capacity can reach 42,000 t /d

Equipment parameters:

Aogenous tumbling mill: ouble motor-driven semi-autogenous grinding mill with diameter of 11× 5.4 meters, total power is 2 × 6343kW

Ball mill:

7.9 m × 13.6 m double motor driven overflow ball mill with a total power of 2 × 8500 kW.

Case 2

Project:

When Dexing Copper Mine expanded the mining and production scale, then in the technical transformation project installed a new semi-autogenous mill and ball mill for the 22,500 t/d semi-autogenous grinding and ball milling system.

Equipment parameters:

22500 t / d semi-SAG mill plus ball mill grinding system.

SAG mill: Φ10.37×5.19m semi-SAG mill (dual motor drive) motor power is 2×5586kW.

When Dexing Copper Mine expanded the mining and production scale, then in the technical transformation project installed a new semi-autogenous mill and ball mill for the 22,500 t/d semi-autogenous grinding and ball milling system.

22500 t / d semi-SAG mill plus ball mill grinding system.

SAG mill: Φ10.37×5.19m semi-SAG mill (dual motor drive) motor power is 2×5586kW.

Production Capacity

Quality Control

Company Profie

Our Business

Custom Visiting

FAQ