Zeolite Grinding Mill Ball 100 Micron Small Raymond Grinding Mill Bentonite Raymond Grinding Mill Lithium in OPEC

US $6,850.00-7,000.00 / set

1 set(s)Minimum order

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Core Components:

Engine, Bearing, Gearbox, motor, Pressure vessel, Gear

Type:

Ball Mill

Motor Type:

AC Motor

Capacity(t/h):

1.9-2.6

Privacy Policy:

Samples are free within a certain price range

Other recommendations for your business

Contact us

Quik Detail

| Video outgoing-inspection | Provided |

|---|---|

| Machinery Test Report | Provided |

| Core Components | Engine, Bearing, Gearbox, motor, Pressure vessel, Gear |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Capacity(t/h) | 1.9-2.6 |

| Place of Origin | Henan, China |

| Brand Name | TYM |

| Dimension(L*W*H) | 300*160/880*160 |

| Weight | 4200 KG |

| Warranty | 1 Year |

| Product name | Ball Mill Machine |

| Application | Stone Powder Grinding |

| Color | Customer Requirement |

| Installation | Engineer's Guide |

| Usage | Grinding Mining Stone |

| Grinding media | Manganese Steel Ball |

| The Machines classification | Granding Mill Machine |

| Factory Visit | Welcomed Warmly |

| Price | Negotiable Resonable |

| Feature | Low Pollution |

Product Detail

Products Description

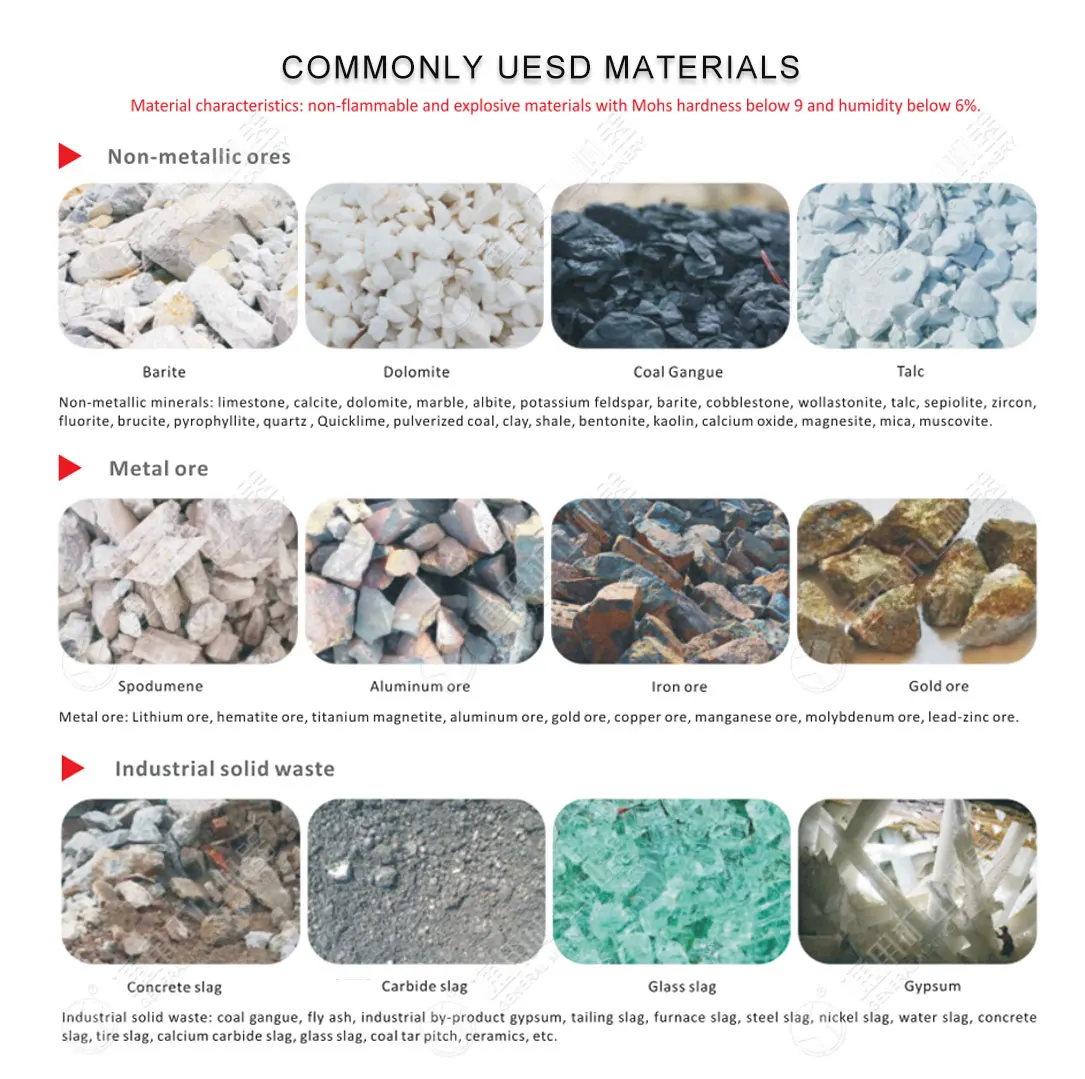

Raymond Grinder (Raymond Mill) is used to grind barite, calcite, potash feldspar, talcum, marble,limestone, and slag below scale 7 of Moth'S hardness and 280-odd sorts of non-inflammable and non-explosive stuff in the traded of mining, building material, chemical engineering and metallurgy for power generation and processing.

The product size is adjustable on required in the range of 80-425 meshes. Some of the materials up to 2,000 mesh.

Working principles

Load the stuff for grinding evenly and continuously into the grinding chamber of the main frame. Due to the centrifugal force in rotation, the roller swings outward and presses closely upon the ring. The shovel carries the stuff to the space between the roller and ring.When the roller rolls,the stuff is thus grind.

Load the stuff for grinding evenly and continuously into the grinding chamber of the main frame. Due to the centrifugal force in rotation, the roller swings outward and presses closely upon the ring. The shovel carries the stuff to the space between the roller and ring.When the roller rolls,the stuff is thus grind.

Grinding mill classifier

Medium body

grinding mill main unit

New type cage classifier

The classifier adopts a built-in large blade cone turbine classifier, and the particle size of the finished product can be adjusted within 60-400 mesh, which improves the classification.

New Reducer

The reducer is changed to a new type of reducer. The speed of the main machine can be changed from a single speed to an appropriate adjustment of the main machine speed according to the needs of users, and the grinding force is increased to increase the output.

Internal structure of the mill

Larger size grinding rollers and ring with less rollers designing. Compared with traditional models of the same price,the grinding capacity increased 20%, because the conveying space of the grinding chamber is increased, and the conveying resistance is reduced.

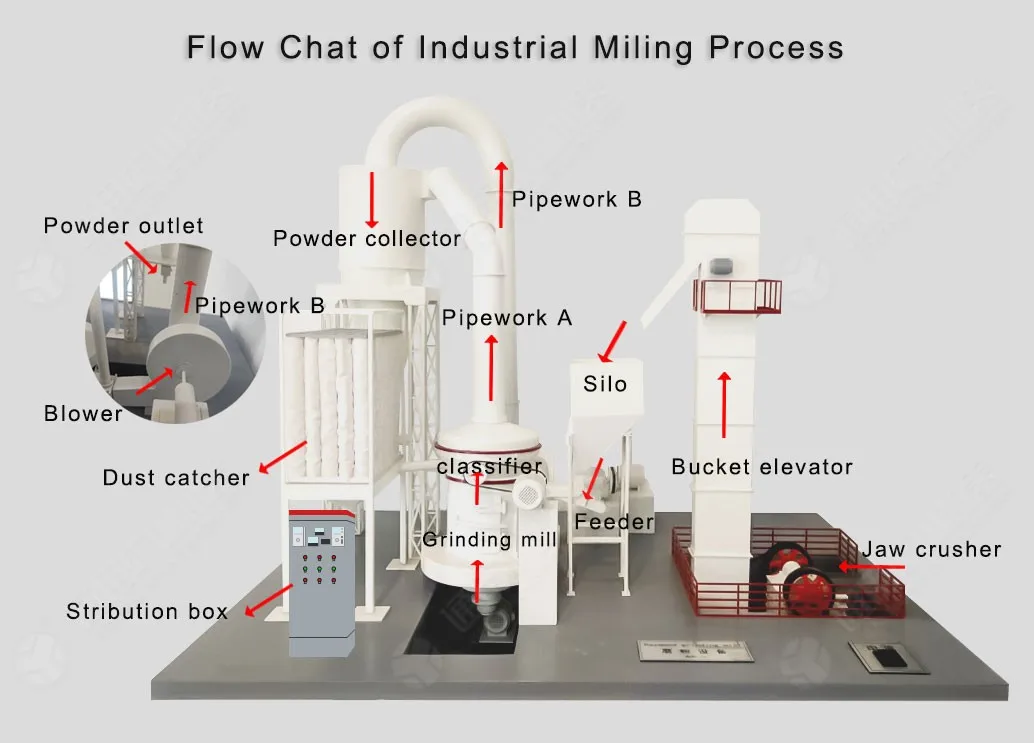

Milling Production Line

Material after jaw crusher, bucket elevator sent by the storage silo, by electromagnetic vibrating feeder evenly continuously sent to the host material for grinding, polishing powder separator after blowing blower in action sorting machines, powder after sorting by pipeline to the storagesilos, and finally by the outlet valve output is finished.

Entire production line work process pressure is negative, the first fan blowing air through pipes accompanied powder into the storage silo upper cyclone collector, returned by the return air blower pipe to form air recycling. Secondly, powder collector with the bottom lock powder feeder, its role is to set the external positive pressure gas and powder isolated negative pressure gas, greatly improving the yield. Again, the bottom of the host residual air and dust were sent through a pipeline to filter baghouse dust and other impurities are adsorbed baghouse, effective protection of the environment.

Entire production line work process pressure is negative, the first fan blowing air through pipes accompanied powder into the storage silo upper cyclone collector, returned by the return air blower pipe to form air recycling. Secondly, powder collector with the bottom lock powder feeder, its role is to set the external positive pressure gas and powder isolated negative pressure gas, greatly improving the yield. Again, the bottom of the host residual air and dust were sent through a pipeline to filter baghouse dust and other impurities are adsorbed baghouse, effective protection of the environment.

It is mainly used in the field of metallurgy, building materials, chemicals, mining and such mineral materials for grinding process. This mill can grind materials with Mohs hardness below 9.3 and humidity below 6%, variousnon-tlammable mineral materials„, such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble,ceramics, bauxite, manganese ore, iron ore, copperore, phosphate rock, iron oxide red, Zircon sand, slagand so on.

Main technical parameters

Model | Grinding roller nummer | Max.feeding size(mm) | The final size(mm) | Capacity(t) | Power(kw) | Overall dimension(m) |

YGM65 | 3 | 15 | 0.613-0.033 | 0.4-1.8 | 15 | 4.1*3.3*4.5 |

YGM75 | 3 | 15 | 0.613-0.033 | 1-3 | 18.5 | 4.3*3.5*5.1 |

YGM85 | 3 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5.3*4.1*5.2 |

YGM95 | 4 | 25 | 0.613-0.033 | 2.1-5.6 | 37 | 7.1*5.9*7.9 |

YGM130 | 5 | 30 | 0.613-0.033 | 3-9.5 | 75 | 7.85*8*9.7 |

YGM1500 | 4 | 30 | 0.95-0.038 | 5-10 | 90 | 11.15*7.48*10.23 |

YGM160 | 6 | 35 | 1.9-0.045 | 8-16 | 132 | 12.55*7.5*8.355 |

YGM190 | 5 | 35 | 0.613-0.033 | 12-26 | 200 | 11.47*6.94*9.58 |

Recommend Products

Our Customers Site

Our factory is specialized in the production of Raymond grinding mill for more than 20 years, is the leading brand in the industry. We have accumulated rich practical experience, and the case sites cover more than 30 countries in the world, including mining, cement, metallurgy, chemical, construction waste and other fields. We can provide EPC project general contracting and other complete solutions.

This is our limestone grinding mill site in Zambian!

The customer's requirements:

Raw material: limestone, capacity: 25 tons/hour, finished products: 200mesh.

Raw material: limestone, capacity: 25 tons/hour, finished products: 200mesh.

Equipment configuration: 2 sets YGM160.

This is our Kaolin grinding mill site in Thailand!

The customer's requirements:

Raw material: Kaolin, capacity: 3 tons/hour, finished products: 325mesh.

Raw material: Kaolin, capacity: 3 tons/hour, finished products: 325mesh.

Equipment configuration: MTW110.

This is our bentonite grinding mill site in Lebanon!

The customer's requirements:

Raw material: Bentonite, capacity: 8 tons/hour, finished products: 200-250mesh.

Raw material: Bentonite, capacity: 8 tons/hour, finished products: 200-250mesh.

Equipment configuration: MTW110.

This is our bentonite grinding mill site in Columbia!

The customer's requirements:

Raw material: Gypsum, capacity: 8 tons/hour, finished products: 300mesh.

Raw material: Gypsum, capacity: 8 tons/hour, finished products: 300mesh.

Equipment configuration: YGM1500.

Packing & Shipping

The package of all equipment is accord with the standard protective measures.The packing is suitable for short and long distance transportation. The moisture proof, quake proof, protected against dampness, and rustproof protection measures were taken to ensure the machine shipping to customers safely. All the machine will be packaged by plastic film.

Plastic film packaging

Large items will be wrapped in plastic film, such as jaw crusher, impact crusher, cone crusher, main mill, pipe, etc.

Box wooden packing

Small parts will be packed in wooden box, such as bolts, rubber sleeves, springs, etc

Company Information

Since in 2004, Zhengzhou General Mining Machinery Co.,Ltd has been the professional manufacturer of Grinding Mill, crushers and sand making machines,etc.

TYM is committed to helping more users around the world to obtain higher profits and faster return on value. Our main products are European Version Grinding Mill, Raymond Grinding Mill, High Pressure Suspension Roller Mill, Micro-powder Grinding Mill, Jaw Crushers, Impact Crushers, Hammer Crusher, Compound Crushers, Ball Mill, nine series of products with more than 30 kinds of specifications.

Our factory

Our factory covers an area of 120,000 square meters and manufactures TYM brand Mining Machinery,has passed international ISO:9001, GOST and CE certification.

Crushing equipment showroom!

Sand making equipment showroom!

Grinding mill showroom!

Grinding mill showroom!

CNC manufacturing shop!

Improve production efficiency!

Shorten the production cycle!

Certifications

Our Services

Warranty

100% brand new when leaving the factory. The seller guarantee quality of the machines (excluding wearing parts) for a period of one year from the date of trial run finish under our technician's guidance, but not exceed 15 months from date on which machine leaves the factory.

Pre-sale services:(1) Device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program.

Sale services:

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

Sales tracking :

(1) product acceptance.

(2) to help customers develop construction programs.

After-sale services :

(1) Guiding customers' installation.

(2) On-site training of operators.

(3) Complete sets of equipment installed, 1-2 full-time technical staff to stay free of charge to help customers on-site production of 1 month, until the user' satisfaction.

Contact us