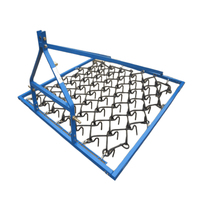

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

3 point drag harrow

Types of 3 point drag harrow

A 3 point drag harrow is a piece of equipment that comes in different types, shapes, and sizes, each designed for a specific use. The types of 3 point drag harrow mainly depend on the material and structure of the drag harrow.

-

Chain Harrow

The chain drag harrow is often made of multiple linked chains, with each set linked at its ends to form a rectangular frame. As an implement pulled behind a tractor, it levels soil, smooth out farm fields, and even helps in the light burial of seeds.

-

Tine Drag Harrow

Often referred to as a drag harrow with flexible teeth, this model features multiple rows of flexible metal tines, all resting on a sturdy frame. The foible of the tines allows them to easily break up clumps of soil, thereby leveling fields. This makes the 3 point tine harrow all the more useful in carrying out the preparation of the seedbed, filling in potholes, and even aiding in turf renovation.

-

Disc Drag Harrow

As a variation of the 3-point hitch drag harrow, the disc harrow features many small, round steel discs with a rim to support them—generally arranged in a series of overlapping rows. When towed or dragged behind the ATV/UTV/tractor, they tilt, thereby striking and turning the soil. This opens up the earth, making it ready for planting and also eliminating weeds.

-

Spring-Teeth Drag Harrow

With a setup resembling a large rake, the spring teeth drag harrow features numerous arched metal springs with teeth attached to them. The springs offer a bouncing action when dragged over the soil. This bouncing effect easily breaks up clumped dirt, levels the surface, and lightly moves over debris. This particular drag harrow works well for pasture fields, gravel roads, and driveways.

Specification and Maintenance

- Available Sizes: 3 point drag harrows usually come in varied widths to match diverse drag bar spread widths. Common widths consist of 4 ft, 5 ft, 6 ft, 7 ft, 8 ft, 9 ft, 10 ft, and 12 ft.

- Number of Rows of Tines: Drag harrows include distinct row units for tines or spikes. The amount of tine rows varies according to the drag harrow size and model. Common tine row numbers comprise 4, 5, and 6.

- Number of Tines per Row: Each row unit additionally comprises a different number of tines. Depending on the drag harrow's size and style, the tines per row may consist of 4, 5, 6, or more.

- Tine Patterns: Tine spacing impacts the harrowing level. A typical drag harrow has overlapping round patterns, perfect for general fieldwork. Other patterns, including narrow, overlapping, and wide-spaced round patterns, are available for specialized uses.

- Tine Types: A drag harrow usually comes with distinct kinds of tines, including sturdy steel flat tines for light to average tasks, round tines for less field damage and better soil aeration, spike tines for shallow drawing, and zigzag tines for higher soil turnover.

Proper maintenance is essential for a three-point drag harrow to ensure its durability and optimal performance. Here are a few maintenance tips:

- Regular cleaning: After use, the operator should take time to clean the harrow thoroughly. This helps to prevent dirt, buildup, and debris from clogging and causing damage to vital components.

- Lubrication: Regularly lubricate moving parts of the drag harrow, including pivots, bearings, and axles, and apply grease to the critical lubrication points. This minimizes friction and prevents rapid wear and tear.

- Fastener checks: Regularly check the drag harrow's fasteners and hitch connections to ensure they are secure and at the correct tension. This helps to avoid unintentional component failure during operation.

- Rust-proofing: For drag harrows constructed of metal, apply a metal rust-proof solution or paint to help prevent rust and extend the life of the harrow.

- Storage: After use, store the drag harrow in a dry and ventilated place away from direct sunlight. This is essential to avoid damage and malfunctions caused by weather effects.

3 Point Drag Harrow Scenarios

-

Small Farm Owner:

A small farm owner has a 5-acre piece of land where he grows vegetables and raises some livestock. He uses a 3-point drag harrow behind his tractor to take care of the pasture where his cows graze. With the drag harrow, he can easily spread out the manure so that the grass grows well, and each section of the land gets fertilized. He also uses it to break up the soil before planting his vegetable seeds. The drag harrow creates an optimal environment for his vegetables and cows, allowing him to efficiently manage his whole 5-acre property.

-

Equestrian Center Manager:

The manager at a large equestrian center has multiple riding arenas used for both training and recreational purposes. To keep the footing of the outdoor and indoor arenas well-maintained and even for the horses, she regularly drags them. She attaches a 3-point drag harrow to a small tractor that can maneuver through the different arenas. After raking the sand or dirt footing with the harrow, it helps eliminate hard and soft places. The horses have better footing, which helps keep them safe and comfortable when riding. Using the drag harrow ensures the equestrian center's riding areas are in excellent condition and always ready to accommodate all horse riders efficiently.

-

Landscaping Business:

A landscaping business serves residential and commercial customers. To prepare the grounds for new turf, shrubs, and flower beds, the owner drags a 3-point harrow behind a compact utility tractor. With the harrow, he can finely grade the soil of disturbed or bare areas. This creates an ideal seedbed for quickly establishing new plantings. The ability to level and improve soil conditions with the 3-point drag allows the landscaping company to provide professional, complete services that bring each property back to life beautifully and enhances the company's reputation with fine-quality work.

How to choose 3 point drag harrows

When choosing a 3 point drag harrow, a few factors should be taken into consideration to ensure that it is well-suited for the applications at hand. Before purchasing a drag harrow fence, buyers should identify their primary use and determine the conditions in which they will use the drag harrow. This includes the types of soil and terrain, as well as the size of their pasture or farm. Afterward, buyers should consider the sizes of drag harrows available and choose one with a wide enough harrowing width to get the job done efficiently. It should also be compatible with their three-point hitch category.

Also, most drag harrows have different tooth and axle configurations that result in distinct soil and turf finishes. Buyers should research the various types of drag harrows and choose one with a finish that is suited for their desired end product. For instance, a chain drag harrow may be well-suited for working with sandy soils, while a double drag harrow may be more suited for clay soil. The number of passes that a drag harrow needs to make has a lot of influence on the efficiency of the harrow used.

At this point, buyers can compare the number of passes a drag harrow needs to make to obtain a fine tillage and make an informed choice. In most cases, wider and heavier drag harrows will do a better job than smaller and lighter ones. If it takes only three passes to get the desired result with a wider drag harrow, a smaller one may need to cover the same area five times to achieve a similar result. Buyers should consider the relationships between sizes, weights, and efficiencies and choose a drag harrow that has a more efficient working width per unit of weight.

Finally, buyers should consider their preferred type of drag harrow. Their choices should be informed by their tractors' HP rating and lift capacity, as well as the 3 point drag harrow's required power and weight. A drag harrow that is too heavy for a tractor will not be effective, while one that is too light may work, but its efficiency will be significantly lower.

3 point drag harrow Q&A

Q1: How does a 3-point drag harrow attach to a tractor?

A1: A 3-point drag harrow connects to a tractor hitch via three attachment points. The top link, which is the central curved link, provides the angle and extends for depth control. The two side links are parallel to the hitch point and connect to the lower hitch points.

Q2: What are some advantages of the 3 point drag harrow?

A2: The three-point drag harrow has various benefits. It is a versatile tool useful for soil preparation, pasture management, and landscaping. The implement is easy to back up and maneuver in close quarters. It provides an adjustable and controlled depth of dragging. The three-point hitch gives better stability and control, and this enables the 3-point harrow to cover uneven terrain compared to the two-point hitch drag.

Q3: What are the different types of 3-point harrows?

A3: The 3-point hitch drag harrow, which this article discusses, is different from the 3-point vertical disc harrow. Moreover, the drag harrow comes in different shapes and sizes, such as the rectangular or square drag harrow and the diamond drag harrow.

Q4: What are the depth settings for a 3-point drag harrow?

A4: Depth settings depend on the task at hand. For surface mixing or seedbed preparation, a shallow setting of 1 to 2 inches is okay. If the focus is on clearing debris or leveling rough ground, then the average setting of 2 to 4 inches is ideal. When working on pastures, a careful setting of 1 to 2 inches will suffice. Users must take note of the operating speed. Using a high speed with a shallow setting can damage the equipment.