400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

BAVA 400w samsung Lm301h Far Red Uvb Veg Bloom Switch Growing Lamps Led Grow Light All Full Spectrum

400 w uv lamp

Supplier Manufacturing Professional Led Grow Light 1000W Led Plant Growth Lamp for Greenhouse Plants

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

400 w uv lamp

Types of 400W UV Lamp

A 400W UV lamp is a powerful ultraviolet light source commonly used in various applications, including curing inks and resins, tanning, and phototherapy. There are different types of 400W UV lamps, which vary in their specific UV wavelengths and technologies. Here are some of them:

-

Mercury Vapor Lamps

Mercury vapor 400W UV lamps consist of mercury gas in a tube. They are heated to produce UV light. The lamps are classified into H and L types. The H type emits a higher intensity UV light. The L type produces lower intensity light, and they are used in applications like curing and tanning.

-

Metal Halide Lamps

These UV lamps are made with mercury and other metals like iodine and bromine. The metal halide lamps give a brighter and more efficient light. They are commonly used in curing processes for inks and coatings.

-

Mercury-Free Lamps

These 400W UV lamps are made with different technologies that produce UV light without mercury. They are safer and more environmentally friendly. The lamps use different technologies like LEDs and excimer lamps.

-

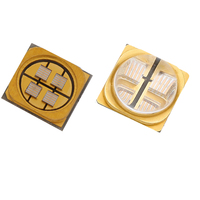

LED UV Lamps

LEDs are popular in many industries because they are energy efficient. They produce very little heat. The 400W LED UV lamps are used for curing processes. They are made to cure specific inks, coatings and adhesives.

-

Black Lights

These are special 400W UV lamps that emit long wave UV light. They are useful for creating effects in art and parties. They make fluorescent materials and dyes to glow in the dark.

Function and features of 400w uv lamp

There are several features of a 400w UV lamp, which include the following;

-

High-intensity UV light

A 400-watt UV lamp emits a high-intensity UV light used to cure or dry photosensitive inks, coatings, and adhesives. This is because the UV light causes a chemical reaction that cures the inks and adhesives, creating a permanent bond that dries them completely.

-

UV wavelength

The UV lamp emits light at different wavelengths, mainly between 200nm and 400nm. This range of wavelengths is suitable for different types of UV-sensitive inks, coatings, and adhesives. The UV lamp generates a lot of heat, which needs to be managed to prevent damage to the material being cured. Some UV lamps have built-in cooling systems, while others use external cooling systems.

-

Adjustable intensity and exposure time

A 400w UV lamp has adjustable intensity and exposure time. It allows users to customize the curing process according to their needs. This feature is important for curing different types of inks, coatings, and adhesives. The lamp also has a long lifespan. It means it can be used for long hours without requiring frequent replacements. This reduces the cost of maintenance and increases its value for users.

-

Easy to use

The lamp is easy to use.It is compatible with different UV curing systems. The UV lamp is versatile and can be used in different industries like graphic printing, optical manufacturing, electronics, and automotive.400w UV lamps are suitable for curing large areas or materials with high viscosity.

-

Portability

Some 400w UV lamps are portable. They can be moved from one place to another and used in different settings. The lamp can be integrated into existing UV curing systems. It makes it a cost-effective solution for users who want to upgrade their curing systems.

Scenarios of 400w UV Lamp

The 400w UV lamp is widely used in various industries. This is due to its ability to emit high levels of ultraviolet light required for different applications. Here are some common usage scenarios.

-

UV Lamps for Curing Coatings and Inks

The 400w UV lamp is primarily used for curing inks and coatings in printing and manufacturing industries. The high intensity of the UV light helps to trigger photochemical reactions. This transforms liquid inks and coatings into solid polymers. The UV curing process is widely used in various applications. For instance, it is used in the production of glossy prints, protective coatings for labels and packaging. It is also used in the manufacturing of UV-cured adhesives.

-

Medical Applications

These lamps are also used in medical applications. For instance, during phototherapy for skin conditions like psoriasis and eczema. The 400nm UVB lamps are beneficial in these treatments as they help to suppress inflammatory responses. Additionally, UV-C lamps are widely used in sterilization and disinfection. The lamps kill bacteria, viruses, and other pathogens. This makes them widely used in healthcare settings. The lamps provide a quick and efficient way to sanitize surgical equipment and clean air and water.

-

UV Lamps for Plastics and Composites

These lamps are used for curing resins in the manufacturing of plastics and composites. The UV-cured resins offer a quick turnaround time in production. This is mainly because of the immediate curing process as opposed to the chemical curing. The 400w UV lamps are also used in the electronics industry. For instance, to cure conformal coatings on circuit boards. The UV curing process provides enhanced protection against moisture and UV lamp electronics.

-

Beauty and Nail Salons

UV lamps are popular in salons and spas. They are used for curing gel manicures and pedicures. The 400w UV nail lamp helps to harden gel polishes quickly. This ensures long-lasting and chip-resistant nail colors. Additionally, some tanning salons use UV lamps to provide artificial tanning. The lamps emit the required levels of UVA rays for skin tanning.

How to choose 400w uv lamp

When choosing a 400w UV lamp, there are several factors that a retailer should consider to ensure they stock a product that will meet the needs of their target customers. Here are some of them:

-

Application Needs

Different applications require different UV wavelengths. A retailer should ensure they have lamps with various UV wavelengths to cater to different customers needs. Also, the lamps should be compatible with the UV sensitive materials the customers are using.

-

Ballast Type

There are electronic and magnetic ballasts. The electronic ballast is energy efficient and has a high power factor. The magnetic ballast is less expensive but has a higher operating cost. A retailer should stock both ballasts to give their customers the opportunity to choose the one that is compatible with their existing system.

-

Curing Speed

The curing speed is the time it takes for the UV lamp to cure the ink or resin. The lamp that has a high curing speed increases the productivity of the users. When buying UV400 lamps for sale, a business owner should look for the one with a fast curing speed to attract customers who value productivity.

-

Cooling System

A UV lamp that comes with a built-in cooling system is easy to use and more convenient. The cooling system helps to regulate the temperature and prevent overheating. It also ensures the lamp operates at optimal efficiency. A retailer should look for UV lamps with effective cooling systems.

-

Quality and Brand Reputation

A retailer should buy UV lamps from reputable manufacturers. They can read reviews on the internet to get more information about the brand and the quality of their products. Buying from reputable brands will ensure they get high-quality products that will last for a long time.

-

Energy Efficiency

UV lamps consume a lot of power. Retailers should look for energy efficient lamps that will help their customers reduce their energy costs. Energy efficient lamps have electronic ballasts and a high power factor.

-

Ease of Use

Retailers should get UV lamps that are easy to use and maintain. They should pay attention to the lamp setup and the replacement process. Also, they should look for lamps that come with user-friendly features.

400w uv lamp Q&A

Q: What are the applications of a 400W UV lamp?

A: 400W UV lamps are used in various applications, including UV resin curing, gel nail curing, ink curing, and photo printing.

Q: How to maintain and store UV lamps?

A: Proper storage and maintenance of a UV lamp can increase its lifespan. Always unplug the lamp when not in use. Clean the lamp to remove dust or debris. Store the lamp in a cool, dry place away from direct sunlight.

Q: How long should one cure nails using a 400W UV lamp?

A: The curing time depends on the type of nail polish used. With a 400W UV lamp, gel nail polish takes about 2 to 3 minutes to cure completely. Always check the manufacturer's recommendations for the appropriate curing times.

Q: Are UV lamps safe?

A: UV lamps are safe when used as recommended. One can protect themselves from UV exposure by wearing UV-blocking glasses and using sunscreen.