anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

anti static mat

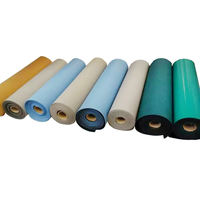

Types of Anti Static Mat

There are several types of anti-static mats, each designed for specific applications and offering different levels of static control. These mats come in different compositions and configurations depending on the requirements for static control, grounding, and durability. Anti-static mat types include:

-

Smear mats

Smear mats are one of the most common types of static control mats. Usually, they feature a sticky top layer that eliminates the need to wipe and clean them after their application. These mats are common in cleanroom settings and applied where debris transfer must be limited. This includes in the semiconductor, electronics, and medical device manufacturing industries.

-

ESD Mats (Electrostatic Discharge Mats)

Usually, ESD mats are designed to protect sensitive electronic components from electrostatic discharge. Commonly, they are made from vinyl, rubber, or other composite materials that dissipate static electricity safely into the ground. These types of static control mats are common in industrial production, laboratory, and computer assembly.

-

Ionizing Air Blower Mats

Normally, ionizing air blower mats are meant for applications that necessitate even quicker neutralization of static charges. Usually, they integrate with installed ionizing air blowers to help create a barrier of ionized air above the floor surface. These types of anti-static floor matting systems find applications in industries like pharmaceuticals, chemical processing, and packaging.

-

Foam Anti-static Mats

A lot of the time, foam anti-static mats come with extra cushioning to protect sensitive components during handling and equipment operation. Normally, they are embedded with static-dissipative layers that give comfort and safety during simultaneous static control. These mats are ideal for use in markets where products require soft surfaces, such as during equipment assembly and in medical device manufacturing.

-

Bench Tops Anti-static Mats

Concrete anti-static mats are customarily designed to coat workbench surfaces and other flat work areas. Normally, they protect the items being worked on from ESD damage. Usually, these mats are produced in a blend with anti-static materials and can be fixed permanently or have a removable configuration depending on the workstation usage.

Features of Anti Static Mat

Anti-static mats have a wide array of features that make them effective and useful in different environments. Normally, these characteristics are tailored to control static electricity, protect sensitive equipment, and provide a safe working space. The major characteristics of these static control mats include:

-

Static Dissipation

Normally, one of the main purposes of anti-static mats is to eliminate harmful static charges. Commonly, most of these mats are built to slowly dissipate static electricity through their surface so that no charge builds up on items placed on them. This feature protects sensitive electronic components from damage caused by electrostatic discharge (ESD).

-

Grounding Capability

Usually, anti-static mats include a grounding system that allows excess static charges to be released safely into the earth. Often, this is accomplished by including a conductive layer within the mat that is connected to a grounded point. Inappropriately, this feature is useful when protecting personnel and equipment from static shock in conjunction with grounding straps.

-

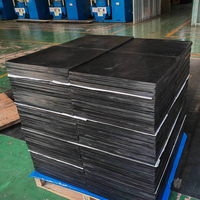

Durability and Resistance to Chemcals

In most cases, anti-static mats are manufactured using solid materials like rubber, vinyl, or foam. This is for the purpose of ensuring they have a high level of durability and are resilient in the face of adverse settings. Moreover, mats are frequently rated for chemical and abrasion resistance, which makes them useful in sectors that require protection against hazardous substances or heavy use, such as industrial applications. antistatic floor matting can also have water-resistant properties, making them ideal for use in humid areas.

-

Surface Texture and Grip

Usually, the anti-static mat surfaces are ideally designed to have a good grip for prevention slipping and sliding. This is important because many of these mats are used in high-traffic areas or where personnel may be moving equipment around. In addition, diverse surface textures provide alternate degrees of cushion and protection to materials placed on the mat.

-

Portability and Flexibility

Occasionally, some anti-static mats are produced to enable portability, hence making it easy to transfer from one location to another. In addition, these portable anti-static mats are usually lightweight and foldable, making them ideal for use in different workstations. This is in contrast to permanent installations, which do not allow for flexibility in use.

Commercial Uses of Anti Static Mat

Anti-static mats are widely used in various industries where static control is crucial for operational safety, efficiency, and product integrity. Normally, the commercial applications of these static control mats include:

-

Electronics Manufacturing

Anti-static mats are vital for the protection of electronic components during the production process in the electronics manufacturing industry. These ESD-safe products minimize the danger of electrostatic discharge, which can destroy sensitive parts and circuit boards. Usually, they are used in assembly areas, testing labs, and production floors where devices such as smartphones, computers, and industrial machinery components are manufactured.

-

Semiconductor Industry

The semiconductor business, where small electronic components are produced, benefits greatly from the use of anti-static mats. Usually, these materials help avoid static damage during handling and processing in a sector that is especially sensitive to ESD. In addition, anti-static mats are often used in cleanrooms, where contamination and static charges must be strictly regulated.

-

Medical Device Production

In the medical device production industry, anti-static mats are frequently employed. Normally, they protect sensitive components and equipment throughout the creation of gadgets such as diagnostic equipment, surgical instruments, and implants. These mats ensure that medical equipment functions safely and effectively by reducing static-related damage.

-

Industrial and Manufacturing Settings

Commonly, many industrial and manufacturing environments use anti-static mats to lessen static charges on machinery, tools, and components. This is particularly critical in heavy manufacturing, chemical processing, and packaging businesses, where static discharge can cause production interruptions or endanger safety. Anti-static mats are also used to ground personnel and equipment, increasing workplace safety.

-

Office and IT Settings

In office and IT environments, anti-static mats protect computer hardware and other electronic gadgets. Normally, they are placed in server rooms, data centers, and IT support areas to prevent static damage to essential equipment such as servers, routers, and workstations. Their use in these fields contributes to the longevity and improved performance of electronic devices.

How to Choose Anti Static Mat

When choosing an anti-static mat, several factors need to be considered to ensure the mat meets the specific requirements for static control, durability, and application. These variables include.

-

Resistance Levels

Normally, different static control mats have diverse resistivity levels, affecting their capability to disperse electric charge. Standardly, for environments like electronics creation, low-resistance mats are warranted to dissipate charge quickly. Conversely, high-resistance mats are better suited for tasks entailing slower charge dispersion. Usually, this is because it allows a build-up, which can be harmless in non-sensitive contexts but dangerous in delicate electronic operations.

-

Material Composition

In most cases, anti-static mats are produced either from vinyl, rubber, or foam. This is due to a blend of the elements, which will incorporate static-dissipative properties, as well as the different future maturation-line characteristics. Normally, vinyl mats are fairly simple to sanitize and very resistant 'antistatic floor matting' to compound and abrasion. Conversely, in the case of rubber mats, which provide added cushioning, they are very robust, which are ideal in industrial workspaces. While Selecting a material, it is important to note the working environment and anticipated use.

-

Application Requirements

Normally, it is important to select an anti-static mat based on the particular context in which it will be used. For example, cleanrooms and other sterile areas normally require smear mats because of their simple disposal characteristic. In addition, industrial settings where heavy machinery is used demand durable and robust anti-static products in the floor area. Usually, special consideration should also be given to extra features, such as the capability of the anti-static mat to resist chemicals and moisture, which can affect their performance.

-

Bench Tops Anti-static Mats

Moreover, tabletop anti-static mats are essential in workstations where delicate equipment, such as circuit boards and electronic components, is handled. Customarily, these mats supply a static-free surface that defends against ESD damage during product manufacture, testing, or repair. Also, tabletop anti-static mats are available in several sizes, with the most popular ones being 60 x 36 and 96 x 48 cm. This enables running easy adjustments to the mat to fit the workstation space.

-

Bench-top Anti-static Mats

In addition, tabletop anti-static mats are key elements in workstations where handlers deal with delicate items, such as circuit boards and electronic components. These mats create a static-free surface that protects against ESD damage during production, testing, or repair. Normally, tabletop anti-static mats are available in various sizes, the most common being 60 x 36 cm and 96 x 48 cm, allowing easy adjustment to fit the workstation space.

Q & A

Q. What exactly is an anti-static mat?

A. Ideally, an anti-static mat is a specially designed material that minimizes the accumulation and discharge of static electricity. Normally, it provides an important layer of protection for sensitive electronic components. It works by dissipating electrostatic charges safely into the ground, thus preventing damage and ensuring the adequate operation of devices in settings vulnerable to static discharge.

Q. What is the difference between static mats and anti-static mats?

A. While both types of mats aim to mitigate the dangers of static electricity, they have distinct purposes. Ideally, static mats are great for minimizing debris transfer and are widely used in cleanroom settings. On the flip side, anti-static floor mats are mainly designated for grounding personnel and protecting electronic components from electrostatic discharge (ESD).

Q. Is it possible to wash an anti-static mat?

A. Yes, anti-static mats can be safely washed. Nonetheless, the cleaning method depends on the specific type of mat and the materials used in its construction. Usually, many vinyl and rubber mats can be wiped down with ESD-safe cleaners or mild disinfectants. Also, heavy-duty mats may permit wash machine cleaning with gentle cycles.

Q. How long do anti-static mats last?

A. The lifespan of an anti-static mat largely depends on the material, usage conditions, and care taken. Normally, high-quality mats constructed from durable materials are designed to last up to five years, in addition to lower-end models. Moreover, high-end models are manufactured to withstand wear, tear, and environmental factors such as chemicals, moisture, and heavy traffic. These combined with the right maintenance can last anywhere between 5-7 years.