brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

brake disc machine

Types of brake disc machines

A brake disc machine is a piece of equipment used to repair and maintain brake discs, which are essential components of a vehicle's braking system. Brake discs, also known as brake rotors, provide a surface for brake pads to clamp onto, creating the friction needed to slow down or stop a vehicle. There are two main types of brake disc machines: vertical and horizontal machines. Vertical machines are further divided into two types: single and dual.

-

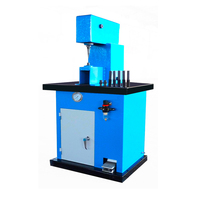

Vertical brake disc machine

This is the most common type of brake disc machine found in workshops. It is designed to be compact and easy to use. The vertical orientation allows for better visibility, making it easier for technicians to work on brake discs. Some vertical machines have single or dual setups. Single brake disc machines have only one lathe, while dual machines have two lathes, one for each side of the brake disc. The benefit of having two lathes is that technicians can work on both sides of the brake disc simultaneously, saving time.

-

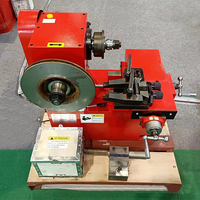

Horizontal brake disc machine

This type of brake disc machine is less common but is still used in some specialized workshops. Horizontal machines allow for more accurate alignment and leveling during the resurfacing process. The horizontal orientation also provides more space for larger brake discs, making it easier to work on heavy-duty or performance vehicles' brake discs.

Besides these two main types, other specialized machines are designed for specific tasks or vehicle types. For example, some machines focus on electric vehicles' brake disc maintenance, while others are designed for high-performance or racing applications. However, all brake disc machines share the same primary purpose: to ensure optimal brake disc performance and safety.

There are also specialized machines designed for specific tasks or vehicle types, such as machines for electric vehicles or high-performance sports cars. However, these are not as common and will not be needed for everyday vehicles.

Specification & Maintenance of Brake Disc Machine

Generally, the brake disc machine is a specialized tool that is used in the maintenance and repair of vehicles. However, brake disc machines come in different specifications depending on the needs and budget of different customers. Here are some of the common specifications of brake disc machines:

-

Brake Disc Machine Capicity

Brake disc machines have different capacities depending on the design and manufacture. The capacity of a brake disc machine is the amount of workload it can handle within a specific time. For instance, a large brake disc machine can be used on a large workshop that has a high brake disc workload. On the other hand, a small brake disc machine is designed for personal use or in a small workshop.

-

Brake Disc Machine Power

Different types of brake disc machines have different powers depending on the usage. The power of a brake disc machine is measured in watts or horsepower. A powerful brake disc machine can generate a higher torque allowing it to handle tough workloads. On the other hand, a small powered brake disc machine can be used for delicate works.

-

Size and weight

Different brake disc machines come in different sizes and weights. Some are portable and lightweight, while others are heavy and large. A large and heavy brake disc machine can handle heavy workloads but can be hard to move. On the other hand, a portable and lightweight brake disc machine is designed for delicate workloads and can be used in tight spaces.

It is important to maintain brake disc machines regularly to ensure efficiency and durability. Here are some of the general maintenance practices for brake disc machines:

- 1. Lubrication: It is important to lubricate the moving parts of the brake disc machine regularly. This ensures that the machine runs smoothly and reduces wear and tear of the components.

- 2. Cleaning: After using a brake disc machine, it is important to clean it to remove brake dust and debris. This prevents the dust and debris from clogging the machine, therefore, increasing its durability.

- 3. Inspect: Regular inspection of the brake disc machine is important because it helps to identify any wear and tear or damage. This makes it easier to replace or repair the damaged components before they cause more damage to the machine.

- 4. Follow manufacturer's instructions: Different types of brake disc machines have different maintenance requirements. It is important to follow the manufacturer's instruction for maintenance and care.

How to Choose Brake Disc Machine

Wholesale buyers can choose a brake disc machine by considering the following factors:

-

Capacity and Size

Brake lathes come in various sizes and have different capacities. Buyers should check the size and capacity of the brake disc machine to ensure it can accommodate the vehicles' brake discs. If the brake disc machine is small, it will limit the types of vehicles and the size of brake discs that can be serviced.

-

Performance and Power

Buyers should check the power and performance of the brake disc machine. A more powerful brake disc machine will provide more efficient and faster service, which will improve productivity. Especially for workshops that service many vehicles.

-

Precision and Quality

Brake disc machining requires high precision and quality to ensure the brake discs meet the manufacturer's standards. Buyers should choose machines that can provide high precision and quality to reduce brake vibration and improve brake effectiveness.

-

Ease of Use and Operation

Buyers should choose machines that are easy to operate and require less skilled personnel. In addition, some machines may have additional functions, such as digital displays or automatic feeding systems, that can simplify the brake disc turning process and improve working efficiency.

-

Quality and Durability

Buyers should choose machines made of high-quality materials and have durable construction to ensure the machines last and require less maintenance. At the same time, they should also consider the warranty period and after-sales service to ensure that they can obtain good support and service from the suppliers.

-

Cost-effectiveness

Finally, buyers should consider the cost-effectiveness of the brake disc machines. This does not only include the initial purchase cost but also the operating cost, maintenance cost, and potential added value, such as improved working efficiency and service quality.

How to DIY and Replace Brake Disc Machine

Most brake disc machines are easy to operate with clear instructions. Here are some general steps on how to operate a brake disc machine:

- Set up the brake disc machine on a stable floor with adequate space and lighting.

- Check the machine's components and ensure it's complete and undamaged.

- Read the manufacturer's instructions to understand the specific features and functions of the machine.

- Plug the brake disc machine into a power source and turn it on.

- Adjust the machine's controls, such as speed and depth, according to the brake discs' condition and the required repair.

- Securely fix the brake discs on the brake disc machine using the appropriate clamps or fixtures.

- Perform necessary repairs or maintenance on the brake discs, such as grinding, cutting, or polishing, as per the machine's functions and the discs' requirements.

- After completing the work, turn off the machine and disconnect it from the power source.

- Carefully remove the brake discs from the machine and clean up the work area.

Because of the complexity and safety concerns related to brake systems, it is recommended to have a trained professional or experienced mechanic to operate and repair brake disc machines if needed.

Below is a general guide on how to replace a brake disc:

- Get the right tools: Ensure the necessary tools are available before starting the replacement process. These include a jack and jack stands, lug wrench, socket wrench, torque wrench, and new brake discs and pads.

- Prepare the vehicle: Park the vehicle on a flat surface and engage the parking brake. Loosen the lug nuts slightly and place the jack under the vehicle to raise it. Once the vehicle is lifted, the jack stands will provide extra support.

- Remove the wheel: Remove the lug nuts completely and take out the wheel to access the brake components.

- Remove the brake caliper: Use a socket wrench to remove the bolts holding the brake caliper. Then, the brake caliper will be loose, and it can be removed from the brake disc. The brake caliper contains brake pads, which are also removed and kept aside.

- Remove the brake disc: Use a socket wrench to remove the bolts holding the brake disc and slide the brake disc off the wheel hub. If the brake disc is stuck, gently knock it loose using a hammer.

- Install the new brake disc: Slide the new brake disc onto the wheel hub and secure it with bolts. Ensure the brake disc is properly aligned.

- Reinstall the brake caliper and wheel: Fit the brake caliper and wheel, then tighten the bolts. Lower the vehicle and remove the jack stands. Once the vehicle is back on the ground, fully tighten the lug nuts using a torque wrench to ensure even pressure.

Q and A

Q. How often should brake discs be replaced?

A. The frequency of brake disc replacement can vary depending on factors such as driving habits, vehicle type, and disc quality. On average, brake discs may need replacement every 30,000 to 70,000 miles. However, users should regularly inspect brake discs for signs of wear and replace them when necessary.

Q. Can users resurface brake discs?

A. Yes, brake discs can be resurfaced. Resurfacing involves machining the disc's surface to create a smooth, even layer. This process can extend the life of existing brake discs. However, there are limits to how much brake discs can be resurfaced. If the discs have significant wear or damage, users need to replace them.

Q. What are the signs of worn-out brake discs?

There are several signs of worn-out brake discs. They include a squeaking or grinding noise when braking, a vibration or pulsation in the brake pedal, uneven disc surfaces, and reduced braking performance. Users should inspect their brake discs as soon as they notice these signs.

Q. Do brake discs need to be replaced in pairs?

A. While it is not mandatory to replace brake discs in pairs, doing so is often recommended. Replacing brake discs in pairs helps maintain balanced braking performance and ensures all wheels have similar grip and response. If users replace only one disc, there may be differences in braking performance between wheels.

Q. Can users install brake discs themselves?

A. Brake disc installation requires precise and careful handling. Users need to have the right tools and knowledge about brake systems. If they are not confident in their ability to install brake discs correctly, it is advisable to seek assistance from professional mechanics.