brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

brass extrusion

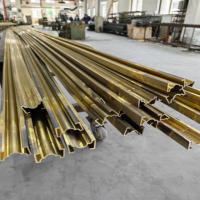

Introduction to Brass Extrusion

Brass extrusion is a vital manufacturing process in which heated brass alloy is shaped into specific profiles through a die. This technique is widely utilized in various industries due to the impressive combination of strength, corrosion resistance, and machinability properties inherent in brass. The manipulation of brass into custom shapes allows for a broad spectrum of applications, ranging from architectural components to industrial machinery parts. Understanding the different aspects of brass extrusion can help businesses select the right products for their specific needs.

Types of Brass Extrusion

Brass extrusion can be categorized based on several criteria, including the alloy composition, manufacturing method, and application. Below are the primary types of brass extrusion:

- Standard Brass Extrusions: These are commonly used in various industries, offering moderate strength and excellent corrosion resistance.

- High-Strength Brass Extrusions: Engineered for demanding applications, these extrusions provide enhanced mechanical properties.

- Architectural Brass Extrusions: Used mainly in building and construction, these have aesthetic appeal and durability for exterior applications.

- Custom Brass Extrusions: Tailored to meet specific design criteria, these extrusions are essential for unique applications and innovations.

Applications of Brass Extrusion

The versatility of brass extrusion leads to its application in multiple sectors, showcasing its essential role in modern manufacturing. Consider the following prominent applications:

- Electrical Components: Brass extrusions are often used in connectors, terminals, and other electrical parts due to their excellent conductivity.

- Automotive Parts: In vehicles, these extrusions can be found in fittings, brackets, and various engine components, providing durability under high-stress conditions.

- Plumbing Fixtures: The corrosion resistance of brass makes it a popular choice for pipes, valves, and faucets.

- Decorative Items: Brass extrusions contribute to aesthetically pleasing applications such as hardware, lighting fixtures, and furniture accents.

Advantages of Using Brass Extrusion

Choosing brass extrusion for your projects comes with several noteworthy advantages that enhance performance and reliability. Here are some benefits:

- Corrosion Resistance: Brass possesses inherent corrosion-resistant properties, making it suitable for environments exposed to moisture.

- Machinability: Brass extrusion can be easily machined and manipulated, allowing for versatile design options and reduced manufacturing costs.

- Strength: Offering a good balance between strength and weight, brass extrusions can withstand significant pressure without deforming.

- Aesthetic Appeal: Its warm finish gives brass an attractive appearance, making it an excellent choice for visible components in design applications.

With these attributes, brass extrusion stands out as a reliable and versatile material suited for various industrial and commercial purposes. Understanding its types, applications, and advantages equips businesses with the knowledge needed to leverage this fantastic material in their operations.