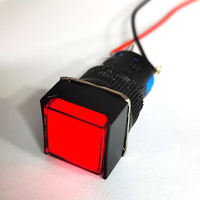

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

button switch

Types of button switch

Instrument pushbuttons can be classified into several types based on certain operating principle, function, and application. Knowing this can help users select the right push button switch according to the needed requirements for any electronic or electrical device.

Normal open button switch

A normally-open button switch is with a form of contact which is open by default. They only close to allow electricity to flow when the button is pressed. This kind of switch is mostly used for actions, like activating devices, where the system is required to only operate when prompted. For instance, NO switches are implemented in button switches to operate machines, alarms, and other tools requiring operator inputs to function.

Normal closed button switch

Conversely, normally-closed (NC) switches work by staying closed with open contacts when the button is not pressed. Thus, they automatically open the circuit after being pressed. This characteristic makes them suitable for applications that need fail-safe measures. For example, if equipment with an NC switch fails, the button's circuit closed will be cut off, sending out a signal and stopping power.

Momentary button switch

Momentary push button switches are switches where the switch returns to its rest position once released. This is done mostly through mechanical means, such as a spring. Momentary switches can either be NO or NC, meaning that configurations exploit their characteristics in different ways. A good example of this configuration is in security systems, where pressing the button will sound an alarm but needs to be pressed closed to deactivate the alert.

Toggle button switch

Toggle button switches are different from momentary switches because they stay in the set position until changed manually. Toggle switches are available in various configurations with NO, NC, and dual-function contacts. This means these toggle switches are suitable for applications requiring constant circuit retention until manual switches are required. Such applications include control panels and equipment where circuit stability is so vital.

Durability and materials of button switch

The endurance and material composition of push button switches are crucial characteristics, especially in considering the particular application and the environmental place where the switch is likely to be used. This often involves evaluating such parameters as the ratings of the IP and the wear and tear of the switches.

IP rating

IP ratings serve the function of providing standardized information on how well a switch is sealed against solids and liquids. The first digit measures protection against dust invasion, while the second digit measures water resistance. For instance, an IP65 rating ensures complete protection against dust and offers low water ingress protection.

Switches with high IP ratings are generally suitable for industries where devices are exposed to particulates and water, meaning construction, marine, or outdoor equipment. For example, a switch with a higher IP rating could be used for construction work, where dust exposure is a likely occurrence and thus needs extra durability.

Materials used in construction

Materials used to manufacture pushbutton switches greatly influence their durability. For example, a metal switch is more robust than plastic parts because it can withstand impacts and wear. Similarly, metal contacts are more durable than silver or gold alloys that are likely to wear out.

In addition, the materials selected for the enclosures of the given switches also provide a means for the protection of the components from the environmental elements. For example, a marine-grade metal enclosure is resistant to corrosion and moisture and is, therefore, suitable for marine applications.

Furthermore, many button switch components are specifically designed and made to withstand extreme thermal fluctuations, chemical exposure, and mechanical strain. These components are usually found in high-demand industries like oil and gas, chemical processing, or heavy manufacturing.

Testing and certifications

Several other standards and certifications depict the durability of the push button switch, besides the IP ratings and materials. Lookout is often needed for certifications like UL, CSA, and IEC, which include tests for endurance, temperature, and stress exposure, among others. Selecting certified switches usually ensures the end-user that the switches have met international standards for safety and performance.

Commercial value and application of a button switch

Application value refers to the performance and effectiveness of the button switch in its application environment. On the other hand, the commercial value refers to the market demand for various button switches.

Applications in control systems

One of the crucial functions of button switches for sale is to control systems across the board. These systems may range from operational machinery, and their delivered effects include turning systems on/off or switching operating modes. In industries, control systems generally have high frequency and need switches that are effective and durable. There is where the push button switches come into play.

Versatility across industries

The intrinsic versatility of the push button switch means they are used across a multitude of industries. From the electronics consumer sector to industrial machinery and aerospace, these switches have operated as simple human interfaces, allowing the systems to function effectively. This aspect, of their use in different sectors, increases their market demand, putting their commercial value high.

User engagement and product design

User engagement also is an important aspect of push button switches that contributes to their commercial value. In consumer electronics, for instance, the ease of use, ergonomics, and aesthetics of the push button can decide the general product's acceptability. Manufacturers usually integrate customizable switch designs into end products to enhance usability and increase sales.

Sustainability considerations

Trade-off sustainability issues is a considerable aspect of the commercial value of push button switches. It has been reported that some manufacturers are increasingly adopting green practices in their production process, including the use of recyclable materials. This, in the end, positively impacts the environment, ends up improving the brand image and capturing the market segment that is focused on sustainability.

Market dynamics and trends

The commercial value of push button switches keeps changing with market trends. Switches with backlighting, location sensing, or being touch-operated are becoming highly desired as industries lean toward smart technology. Keeping up with these trends helps maintain a policy-compliant business and capture additional market shares, therefore, making it needful for a switch manufacturer to keep adapting to new technologies.

How to choose button switch

Instrument using push button switches should take some parameters into consideration to select the right one. There are some factors that are commonly considered to get the appropriate switch for an application.

Application requirements

This is the first and foremost rule: understand the application's basic needs. It means knowing the electrical parameters (voltage and current) and environmental conditions (temperature, humidity, exposure to dust or water) the switch will be facing. Momentary, NO, and NC switches are ideal for applications requiring temporary activation. In contrast, toggle switches are ideal for applications or systems that need circuit retention.

Load and voltage rating

The load and the voltage rating of the switch have to be in line with the system it will control. Any operation of a switch at values above its designed electrical parameters could damage the switch itself or cause system failure. On the other hand, using a switch with lower voltage or current capacity will lead to increased wear and potential safety hazards. Thus, always ensure the switch has compatible voltage and load ratings with the device needs to control.

Size and form factor

The size and the form factor of the switch are other important considerations. The size of the switch should fit within the system it is intended to be used. Switches come in various designs, such as sealed switches for the environment's dust and moisture exposure or low-profile switches in areas with limited space.

Durability and reliability

The switches used for applications which are vigorously or frequently cycled through should be selected based on their durability and reliability. Look for switches with a high rating of life cycle and made of materials resistant to wear, tear, and environmental factors, including heat, moisture, and chemicals.

Cost considerations

Cost is always a consideration factor in selecting a switch. While budget-friendly options will be available, weighing the long-term benefits of a more durable, efficient switch is worth considering. Sometimes, a more expensive switch at purchase can save much in replacement and downtime costs in the long run.

Q&A

Q1: What is a push button switch?

A1: A push button switch is a mechanism or device that controls a process by controlling or starting the process through the direction of the applied forces from the button.

Q2: What are the types of push button switches?

A2: The types of main push button switches include normally open (NO) and normally closed (NC) switches and toggle switches and momentary switches.

Q3: What are the main parameters to consider when selecting a push button switch?

A3: The main parameters to consider when choosing a button switch for sale are application requirements, load and voltage rating, durability and reliability, size and form factor, and cost considerations.

Q4: What is the importance of IP ratings for push button switches?

A4: The IP rating indicates the enclosure's robustness, protecting the internal parts against the infiltration of water and solid particles, such as dust.

Q5: How do switch materials affect durability?

A5: The materials used to make the contacts and enclosure determine how well the switch can withstand wear and tear. For instance, metal contacts are durable.