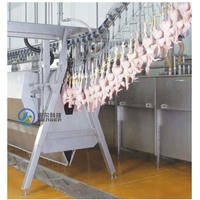

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

chicken plucker machine

Types of chicken plucker machines

A chicken plucker machine, also called a chicken picker machine, comes in different types based on its operational mechanism, suitability for various contexts, efficiency, and capacity. Here are some of them:

-

Rotary Plucker Machine:

The rotary plucker has a drum equipped with rubber fingers or pads. It operates by removing the chicken after scalding it. The scalding process is essential for the skin and hair follicles of the chicken to loosen. Then, the chicken is placed in the rotary plucker, and the rubber fingers or pads strike the chicken to remove the feathers. The rotary pluckers can be electrically or mechanically driven.

-

Finger Plucker Machines:

Finger plucker machines use the same principle as glove finger pluckers. Here, the chicken is placed under a set of rotating fingers made from rubber or soft plastic. These fingers gently pull and extract the chicken feathers as they rotate. The rotary action effectively removes the feathers without causing damage to the chicken. It is common for electric motors to carry out the finger's rotary movement, but some may be driven by belt and pulley systems directly linked to the drivetrain of an automobile or engine. Compared to glove finger pluckers, the rotary versions are usually more effective. Rotary finger pluckers can have various sizes. Smaller units or birds may have a single rotary set of fingers enclosed in a tub.

-

Eviscerating plucker machines:

The role of eviscerating machines goes beyond merely removing feathers. These machines streamline the intricate and time-consuming process of gut extraction, ensuring that the chicken is prepared with precision and efficiency. Such machines have become indispensable in poultry processing facilities that adhere to global standards and cater to commercial markets. These standards necessitate not only the swift removal of feathers but also the rapid and systematic extraction of internal organs. Time is of the essence in these processing plants, and every minute counts when preparing poultry for distribution.

-

Drum chicken plucker machines:

Drum chicken plucker machines operate similarly to rotary plucker machines. However, they are designed to include a rotating drum fitted with small rubber or plastic fingers. The chicken is placed inside the rotating drum, and as it turns, the fingers gently strike the chicken to extract the feathers. The drum's rotation automatically removes the chicken feathers without the need for manual assistance or intervention.

Specifications & Maintenance of Chicken Plucker Machines

-

Capacity:

Based on how many birds it can process at a time, chicken plucking machines have capacities that are different. While some machines are made to handle smaller birds or batches, others may be able to pluck larger fowls at once.

-

Size and dimensions:

The length, width and height of a chicken plucker machine are commonly referred to as its size and dimensions. Plucker machines come in a variety of sizes to suit different spaces and requirements.

-

Power source:

Electric chicken plucker machines require power from the electricity to run. On the other hand, gas-powered chicken pluckers use natural gas or propane as fuel.

-

Skin removal method:

While some machines use discs or finger-like rubber nubs, others may employ vibrating surfaces, rotary drums or other techniques; chicken plucker machines generally remove skin by rubbing, scraping or pulling.

-

Water requirement:

While dry chicken plucking machines don't need any water, wet plucking machines use water and require a certain quantity flowing through them.

-

Durability and corrosion resistance:

Durability and corrosion resistance are key aspects of material selection in the design of chicken pluckers, ensuring that the machines can withstand constant use and are not easily damaged or degraded by environmental factors.

In order for a chicken plucker for sale to perform well for a long time, it has to be serviced constantly. Here are a few of the suggestions on how to develop a regular machine maintenance schedule:

-

After use cleaning:

Residual feathers, fluids, and debris must be removed from the chicken plucker machine and its parts after each usage. This can be easily accomplished by rinsing with water and wiping with a cloth.

-

Lubrication of parts:

Usually, plucker machines are equipped with movable parts like chains, sprockets, and bearings. These components require regular lubrication, which is often carried out by applying lubricants or oils to reduce friction and enable smooth movement.

-

Periodic components inspection:

The success of the chicken plucker machine's continuous operational performance heavily relies upon the periodic inspections of its components. The inspection should focus predominantly upon the machine's skin removal fingers, motors, belts, and other vital parts. These are the places where wear and tear is more likely to occur over time. They should be examined carefully based upon usage frequency to ascertain whether they are functioning normally or need to be replaced.

Application scenarios of chicken plucker machines

Chicken plucker machines are helpful in different settings. Here are some common application scenarios of chicken pluckers.

-

Commercial poultry farms

-

Small-scale poultry farms

-

Poultry processing centers

-

Restaurants and catering services

-

Retail butcher shops

On big poultry farms, chickens are bred for their meat. A chicken plucker machine helps to handle large numbers of birds. It saves time and labor costs. All this leads to higher efficiency and profit margins for the farm.

On small farms, chickens are raised for local markets or home use. Chicken plucker machines for small-scale farms are designed to be compact. They are easy to use. The machines help farmers prepare birds for sale or butchering with ease and speed.

At poultry processing centers, chickens are efficiently cleaned and prepared for packaging. Here, big chicken plucker machines are used. These machines have a high capacity. They reduce the need for manual labor during the plucking process. This helps the center to meet the demands of customers.

Some restaurants and catering services choose to use whole chickens instead of chicken parts. Chicken plucker machines help these businesses by quickly preparing the chickens for cooking and serving. Plucking the chickens on-site cuts down on the amount of services needed to prepare the chicken meat.

Some butcher shops sell poultry alongside other meats. Chicken plucker machines can be used to prepare the birds for sale. Customers want chickens that are fresh and properly cleaned. Chicken pluckers get the job done quickly and satisfy customers' needs.

How to choose chicken plucker machines

Business buyers searching for efficient chicken plucking might consider a few critical factors before purchasing. They should determine the capacity of the chicken plucker. Identify how many chickens typically get processed at a single time or within a given timeframe. Ensure the chosen chicken plucker has the capacity to handle the required volume without causing delays or bottlenecks in the processing flow.

Business buyers need to consider the quality of the chicken plucker machine. To ensure a smooth purchasing process, it is essential to prioritize selecting a chicken plucker machine of excellent quality. A high-quality machine will be more efficient, less prone to breakdowns, and easier to maintain. Choosing a durable, reliable, and well-performing chicken plucker will ultimately save money and resources in the long run.

Is the machine easy to clean? A simple cleaning process is essential for maintaining proper hygiene standards and preventing cross-contamination. Choose a chicken plucker with smooth surfaces, removable parts, and accessible areas for cleaning. Also, consider the availability of spare parts and dealerships for repair services. It ensures that the company can quickly address any issues that may arise in the future.

Finally, a buyer should consider the type of chicken plucker machine before buying. Are they planning to handle large volumes of chickens daily? If so, they may want to invest in a larger capacity chicken plucker. Conversely, a smaller, more compact chicken plucker may be suitable if the space is limited. Additionally, choosing a machine that is easy to operate and comes with clear instructions is essential to minimize training time and maximize efficiency.

Chicken plucker machine Q&A

Q1: Are chicken plucker machines worth it?

A1: Yes, chicken plucker machines are worth it. They save time and effort during the plucking process. They are worth the investment for those who process chickens regularly.

Q2: Where does the chicken plucker go after slaughter?

A2: The chicken plucker comes after the chicken has been harvested. It is advisable to handle the chicken in a clean and sanitized environment to avoid contamination.

Q3: Can a chicken plucker handle other birds?

A3: Yes, many chicken pluckers can handle other birds such as turkeys, ducks, and pheasants. Check the specifications to determine the chicken plucker's suitable bird types.

Q4: Can chicken pluckers be repaired when damaged?

A4: Yes, chicken pluckers can be repaired in case they are damaged. The parts that mainly need repairs are the rubber fingers, motors, and drums. It's important to handle the machine carefully and avoid any damage that might make the machine irreparable.