cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

cold formed steel sections

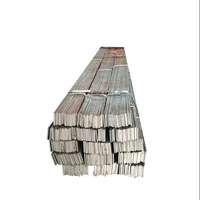

Introduction to Cold Formed Steel Sections

Cold formed steel sections, a staple in modern construction and manufacturing, are versatile components made from thin sheets of steel, shaped through a process of cold rolling. This process imparts strength and durability while maintaining lightweight characteristics. They are widely used in various structural applications due to their superior properties and cost-effectiveness. The popularity of cold formed steel sections can be attributed to their ability to meet varying project requirements while providing high-quality performance.

Types of Cold Formed Steel Sections

- URI Sections: Often used as a main frame or support structure, these sections come in various gauges and sizes, providing excellent load-bearing capacities.

- C-Sections: Resembling the letter 'C', these are widely utilized in walls and roofs for both residential and commercial buildings owing to their ease of installation.

- Hat Sections: Known for their unique shape, hat sections are utilized in applications where strength is required without added weight, such as in railings or braces.

- Box Sections: Featuring a rectangular or square profile, box sections offer exceptional rigidity and are typically used in the fabrication of frames and supports.

- Sigma Sections: These sections are designed for superior bending and are often used in complex structural applications.

Applications of Cold Formed Steel Sections

Cold formed steel sections have a wide array of applications across industries, due to their strength, durability, and cost-efficiency. Common applications include:

- Residential Construction: Used for framing walls and roofs, they serve as the backbone for many residential structures.

- Commercial Buildings: Ideal for office buildings and warehouses, they provide strong structural support with less material overhead.

- Industrial Structures: Frequently utilized in manufacturing and storage facilities to create long-lasting, robust frameworks.

- Transport Infrastructure: Employed in bridge construction and railings, enhancing safety and structural integrity.

- Solar Panel Mounting Systems: Lightweight yet strong, these sections support mounting systems for solar panels efficiently.

Features and Advantages of Cold Formed Steel Sections

Cold formed steel sections boast numerous features and advantages that make them a preferred choice in various construction applications:

- High Strength-to-Weight Ratio: They provide significant structural stable due to high tensile strength while remaining lightweight, allowing for easier handling and transportation.

- Versatility: Available in a wide range of sizes and shapes, they can be tailored to fit specific needs, making them suitable for various applications.

- Crescent Design: The continuous bend design enhances structural integrity, reducing the risk of warping and deformation.

- Corrosion Resistance: Often galvanized or treated, cold formed steel sections resist rust, thereby extending their life span significantly.

- Cost-Efficiency: They are generally more affordable than their hot rolled counterparts, leading to reduced project costs.

- Eco-Friendly Choices: Many manufacturers offer materials that are recyclable, contributing to sustainable building practices.