composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

composite plywood sheets

Types of composite plywood sheets

Composite plywood sheets, also known as engineered wood products, are made of wood veneers or strands and adhesive resins bonded under heat and pressure. They are used in construction, furniture making, and cabinetry where solid wood products would typically be used.

Composite plywood sheets are designed to offer improved strength, stability, and resistance to warping and cracking compared to traditional plywood. They come in various types and applications depending on what the end user wants. Here are the different types:

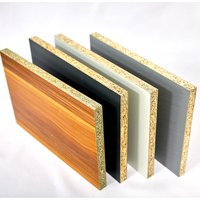

- Melamine Faced Chipboard (MFC): This is a type of composite plywood sheet that has a chipboard core. The core is made of chips of wood and resin bonded together. It has decorative paper layers that are impregnated with melamine resin. These papers are the face layers of the composite board. They are available in different colors and patterns. The boards are available in two types: single-faced MFC boards which have one decorative face and back MFC boards which have one decorative face and a plain back. They are commonly used for furniture construction like cabinets, desks, and drawers.

- Melamine Faced MDF: These composite plywood sheets are made from fine wood fibers and resin bonded to form a dense board. Like MFC, melamine resin is used to create faces with different colors and textures. The boards are available in two types: plain faced boards and plain faced and back boards. They are used for furniture, doors, and decorative panels where a smooth finish is required.

- Particle Board: This type of composite plywood sheet is made from wood chips or particles mixed with adhesive and pressed into a board. It is less expensive and less dense than MDF and is commonly used for budget furniture and cabinetry. It is suitable for applications where high strength and moisture resistance are not required.

- Oriented Strand Board (OSB): These are engineered wood products constructed from strands of wood oriented in specific directions and bonded with adhesives. They are made from large wood strands that are oriented and pressed together with adhesives. OSB is stronger than plywood and is commonly used for roofing, flooring, and wall sheathing. They are used in construction for applications requiring structural support.

- Fiberboard: This type of composite plywood is made from the residuals of wood processed into a fine pulp mixed with adhesive and pressed into a dense board. It is lightweight and easy to work with. They are used for insulation, soundproofing, and lightweight construction applications.

Functions and Features of Composite Plywood Sheets

Composite plywood sheets are engineered wood products designed for strength, stability, and versatility. Here are some key features and functions of these composite plywood sheets.

-

Structural Integrity

Composite plywood sheets are designed for high strength and load-bearing capacity. Their composite nature provides structural integrity and support in various applications, from building frameworks to furniture construction. These sheets offer enhanced strength and stability due to their composite materials.

-

Lightweight

The composite nature of these plywood sheets allows for the creation of lightweight panels without compromising strength. This lightweight characteristic makes them easy to handle and transport, reducing shipping costs and facilitating on-site installation. Additionally, their lightweight nature enhances their versatility in construction and design.

-

Dimensional Stability

These composite plywood sheets offer enhanced stability over traditional solid wood products. They are less prone to warping, bending, and shrinking, especially in environments with varying humidity and temperature. This dimensional stability ensures that the composite plywood maintains its shape and appearance over time, providing a reliable surface for flooring, panelling, and countertops.

-

Moisture Resistance

Many composite plywood sheets are designed with waterproof or water-resistant resin binders. This feature minimizes the absorption of water, making the sheets resistant to rot, fungi, and insect damage. The moisture resistance characteristic allows these sheets to be used in areas with high humidity and moisture. For instance, in kitchens and bathrooms, in addition to being suitable for outdoor applications like decks and gazebo structures.

-

Versatility

These composite plywood sheets can be used in a wide range of applications, including construction, automotive, marine, and aerospace industries. They are used for flooring, roofing, and sheathing in building and construction. They are also used in making furniture, cabinets, and countertops. Due to their lightweight and stable nature, these sheets are also used in the automotive and aerospace industries for interior components and structural parts.

-

Cost-Effectiveness

Composite plywood sheets provide an economical alternative to solid wood or other engineered wood products. Their cost-effectiveness is a result of their competitive pricing per unit area, reduced waste during construction, and lower maintenance costs over their lifespan. Moreover, they offer a good balance of cost and performance, making them attractive for projects with budget-sensitive constraints.

-

Eco-Friendly Options

Manufacturers often use recycled materials, such as wood chips, sawdust, and other industrial by-products, to produce composite plywood. This reduces the need for virgin materials and minimizes waste. Some composite plywood sheets are manufactured with adhesives and resins that have low or no added formaldehyde. This eco-friendly characteristic reduces the emission of volatile organic compounds (VOCs) and improves indoor air quality.

Scenarios of composite plywood sheets

The application of composite plywood sheets is versatile in construction, woodworking, and creative projects. Their strength, stability, and resistance to environmental factors make them suitable for a wide range of uses.

-

Furniture Construction

Composite plywood is widely used in the manufacture of furniture such as cabinets, drawers, shelves, and wardrobes. The engineered wood provides sufficient storage space for the organization of items and enhances the overall aesthetic of the room. It is also used in constructing chairs, sofas, and benches. The reason why composite plywood is a preferred choice in furniture construction is due to its smooth surface that allows for easy painting and attractive customization options.

-

Interior Design and Decoration

Composite plywood sheets are used in the design and construction of interior structures. Examples include: partition walls, paneling, and ceiling tiles. Their versatility allows for a wide range of applications, creating a cozy atmosphere in residential spaces and an elegant atmosphere in commercial spaces. They are also used as backdrops for stage settings and events.

-

Cabinet Making

Cabinets are an essential component of most kitchen and bathroom spaces. Composite plywood offers the perfect material for building cabinets because of its water-resistant properties and strength. They are also aesthetically pleasing, which improves the overall appearance of the kitchen or bathroom. Additionally, the use of composite plywood in cabinet making reduces the amount of waste material generated during production, making it an environmentally friendly option.

-

Flooring

The composite plywood sheets are treated with chemical preservatives that enhance their durability, making them a good option for flooring. They are suitable for use in high-traffic areas like commercial spaces and shopping malls. This engineered wood is also a good option for use in areas with high moisture content, such as kitchens and bathrooms.

-

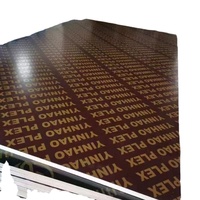

Formwork and Scaffolding

In construction, composite plywood is used to create concrete forms. This allows the builders to mold concrete structures into desired shapes and sizes. The composite plywood sheets offer a smooth surface that enables concrete to slide off easily during demolding. It can be reused several times, thus reducing the overall construction cost. Composite plywood is also used in scaffolding. It is lightweight but strong enough to support workers and materials during elevated construction tasks.

-

Boats and Automotive

Composite plywood sheets are used in the construction of boats because they are waterproof and lightweight. Their resistance to water makes them a good option for building boat hulls and decks. These sheets are also used in constructing the interiors of cars, buses, and other automotive parts.

How to Choose Composite Plywood Sheets

Composite plywood sheets are used for various purposes. Therefore, before purchasing, wholesale buyers should consider some factors to ensure they get the perfect product for their project. Here are some of the factors to consider when choosing composite plywood:

-

Understanding the Project Requirements

Determine the intended application. Is it for furniture construction, cabinetry, flooring, or decorative wall panels? Each application may have specific requirements that need to be considered. Consider the load-bearing capacity needed. If the composite plywood is used for structural purposes, assess the required thickness and strength. Determine if lightweight panels are needed or if more robust options are suitable.

-

Environmental Considerations

Determine if the composite plywood will be used in areas with high moisture content. This is important for projects in kitchens, bathrooms, and outdoor spaces. Choose water-resistant or waterproof options if necessary. Consider the temperature and climate conditions. Extreme heat or cold can affect the performance and longevity of the composite plywood.

-

Evaluating Quality and Durability

Assess the quality of the composite plywood. Look for reputable brands or manufacturers known for producing durable and high-quality products. Examine the manufacturing process if possible. Consider the certifications and standards. Check for industry certifications or comply with standards that guarantee the quality and safety of the composite plywood.

Consider the durability. Look for features that enhance durability, such as high-density construction, moisture resistance, and veneer quality. These factors will ensure the composite plywood has a long lifespan.

-

Budgeting and Cost Analysis

Determine the budget. Establish a budget that considers the overall project costs. This will help in selecting composite plywood sheets that align with the financial constraints. Remember that the cheapest option is not always the best. Consider the long-term value and durability in addition to the upfront cost.

composite plywood sheets Q&A

Q: What are the three types of plywood composites?

A: Structural, non-structural, and overlay plywood are the three types of composite plywood sheets. The structural type is suitable for roof, wall, and subfloor applications. Non-structural plywood is used for interior applications such as cabinetry and furniture. Overlay plywood has a resin-impregnated material bonded to its surface to improve durability and resistance.

Q: What are the disadvantages of composite plywood?

A: The only major disadvantage of composite plywood is that it cannot be repaired once damaged. Unlike solid wood or veneer plywood, it does not offer the option of sanding out imperfections or replacing damaged sections. However, its advantages, such as stability and cost-effectiveness, outweigh the disadvantages.

Q: Which is better, MDF or plywood composite?

A: MDF has a smooth and even surface, which is good for applications where aesthetics are more important than strength, such such as drawer boxes or painted surfaces. MDF is also cheaper than plywood. However, the choice between MDF and plywood depends on the intended use and what is more important between cost and strength.