cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

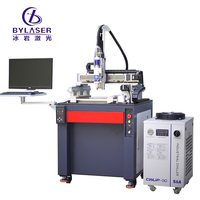

Fiber Laser 50 Jewelry Cutting and Graving 50 W Metallic Laser Printer Marking Name Necklace Machine

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

cutting laser

Types of Cutting Laser

Cutting laser machines are mainly differentiated by their laser types and what materials the laser machine can cut. Therefore, below are the main types of cutting laser machines on the market today:

-

C02 Laser Cutting Machines

These are the most common cutting laser machines that utilize a C02 laser. These machines are predominantly used to cut non-metal materials like acrylic, wood, paper, and glass. These machines can also engrave on several surfaces. C02 laser cutting machines are mostly preferred due to their efficiency in cutting and engraving.

-

Fiber Laser Cutting Machines

These machines are perfect when one needs to cut thin sheets of metal and also work well on reflective materials like copper and brass. The fiber cutting machine makes use of a solid-state laser, which is generated by a fiber optic cable. Fiber laser cutting machines are extremely accurate, hence making them preferred to use for fine and fast cutting.

-

Crystal Laser Cutting Machines

These machines are used mainly for cutting and engraving crystal. A crystal laser cutting machine makes a laser from a C02 laser that passes through a prism made of crystal. This type of laser cutter is excellent for creating intricate designs and 3D images inside crystal blocks.

-

YAG Laser Cutting Machines

These are another type of fiber laser cutting machine that uses a YAG (yttrium aluminum garnet) crystal to generate the laser beam. YAG lasers are usually preferred for cutting and engraving metals. They are powerful and can also be used for other cutting applications.

-

Hybrid Laser Cutting Machines

These machines combine properties of both fiber and YAG laser cutting machines to provide flexibility and efficiency. They can be used for different materials, both metallic and non-metallic. Hybrid laser cuttings are excellent for businesses requiring versatile cutting capabilities.

Industrial Application of Cutting Laser

Across the industrial sector, laser cutters are used widely and in many different ways. Some of these applications include:

-

Cutting Materials

Laser cutters are used predominantly for cutting a variety of materials. C02 laser cutting machines are used frequently in the automotive industry for cutting interior panels, trim, and other non-metal components. Fiber laser cutting machines are commonly used in the aerospace industry to cut parts from thin sheets of metals. Due to their pinpoint accuracy and ability to cut complex shapes, laser cutters have become integral tools in modern manufacturing across a multitude of industries.

-

Precision Engraving

Laser cutters are also used for engraving purposes. For instance, in the electronics industry, laser cutters engrave serial numbers, barcodes, and other identification marks on circuit boards and components. Also, in the medical device industry, laser cutters engrave intricate designs or patterns on surgical instruments for sterilization. Moreover, in the jewelry industry, laser cutters engrave detailed designs on metal pieces for fine intricate designs. Cuit laser machines are preferred for their accuracy and versatility.

-

3D Modeling and Prototyping

Cutting laser machines are used for 3D modeling and prototyping. They are used to create precise scale models in architecture and industrial design. Also, they are used in developing prototypes of products in the initial design stages before mass production. Laser cutters enable from digital designs to physical models quickly.

-

Medical Applications

In the medical field, laser cutters are used to create implants, surgical instruments, and other medical devices with high precision. YAG laser cutting machines are used for cutting metals that are used in internal body implants and also for surgery equipment.

-

Signage and Artwork Creation

Both C02 and fiber laser cutting machines are used to create customized signs and artwork from wood, acrylic, and metal. These machines sculpt out intricate designs that would be difficult to attain using conventional cutting methods. Hence, the laser cutting machines are a popular tool for artists and businesses in this signage and artwork creation.

Durability and Maintenance of Cutting Laser

-

Regular Inspection of Lens and Mirrors

Lasers used for cutting materials have lenses and mirrors that are usually prone to getting smoky and, therefore, need to be cleaned often. If they are not cleaned, they will diminish the laser's power, thus affecting its cutting ability. Depending on the material being cut, smoke residue can build up on these optical components.

-

Cooling System Maintenance

Laser cutters require efficient maintenance to cool systems to avoid overheating. Fiber laser cutting machines have cooling systems that need to be maintained so as to ensure optimum performance. Regular checks on refrigerants and coolant levels are also important.

-

Bed and Rail Maintenance

Cut laser machines have their working beds, and machine rails carry the laser head; thus, their regular cleaning and lubrication are important not only for the equipment's longevity but also for maintaining accuracy too. Residues of materials left on the bed or debris left on the rails can cause misalignment, which in turn makes wear and tear.

-

Regularly Check for Alignment and Calibration

Maintenance and durability checks also require regular alignment and calibration of the laser cutter to ensure even and precise cutting. A miscalibrated laser can lead to poor cutting results and can also damage the machine. Hence, routine calibration checks are integral for maintaining durability and optimal performance.

-

Software Updates and Maintenance

Lasers for cutting, especially in hybrid and crystal laser cutting machines, rely on software for control. These maintenance procedures require software updates and checks to ensure efficient operation. Maintenance of software also includes backing up and restoring design data.

How to Choose Cutting Laser

-

Type of Material

It is necessary to consider the types of materials that the laser cutting machines will be cutting all the time. C02 laser cutting machines are ideal for non-metal materials like wood, acrylic, and paper. On the other hand, fiber and YAG laser cutting machines are suitable for metal materials for their engraving capability.

-

Laser Power

Higher power lasers can cut thicker materials. Therefore, when selecting a laser cutting machine, it is better to consider power for the intended applications. For detailed engraving work, lower power settings are sufficient. For general cutting, which may include cutting metals, higher power lasers are preferred.

-

Bed Size

The size of the laser cutter's working bed should fit the typical material size being utilized. Larger projects may require more extensive bed size; for small projects, a small bed size will be enough. Also, available space at the workshop where the laser cutting machine will be kept should be considered.

-

Budget

Budget is also a factor in choosing a cutting laser. While high-precision laser cutting machines offer better performance, they also come with a cost. It is, therefore, crucial to weigh the prices and achieve a good balance between costs, which include long-term operational costs, and the quality of results needed.

-

Customization Capabilities

For businesses that require tailored products, the choice of laser cutter will greatly depend on the customization capabilities it offers. Laser cutting machines offer high precision, which makes them suitable for creating intricate designs and customized patterns. Such capabilities are particularly advantageous in industries requiring bespoke items, like in signage, jewelry, and in the automotive industry.

Frequently Asked Questions (FAQs)

-

Q1: What materials can be cut with a C02 laser cutting machine?

A1: C02 laser cutting machines are very versatile, especially when cutting non-metal materials like acrylic, wood, paper, and glass.

-

Q2: Why are fiber laser cutting machines preferred for metals?

A2: Fiber laser cutting machines are suitable for cutting material because they offer high precision and are efficient, especially on thin metal sheets.

-

Q3: What is the main advantage of crystal laser cutting machines?

A3: Laser cutting machines for crystal can create intricate designs and 3D images inside crystal blocks, which is their main advantage.

-

Q4: How often should the lenses and mirrors of laser cutters be cleaned?

A4: For optimal performance, it is important to clean the lenses and mirrors after every several cutting or engraving sessions.

-

Q5: What maintenance is required for the cooling system of fiber laser cutters?

A5: Regular checking of refrigerants and coolant levels is integral to preventing overheating and ensuring the system functions properly.