dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

dc motor control board

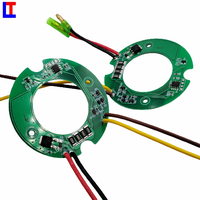

Introduction to DC Motor Control Board

A DC motor control board is a vital component in managing the performance and operation of DC motors. These boards serve as the nerve center, regulating speed, direction, and other operational parameters. With advancements in technology, DC motor control boards have evolved to offer sophisticated functionalities that cater to diverse applications across industries, enhancing efficiency and performance.

Types of DC Motor Control Boards

DC motor control boards come in various configurations, each designed to cater to different motor specifications and usage scenarios. Understanding these types is crucial for selecting the right board for your project.

- H-Bridge Motor Drivers: Ideal for applications that require bidirectional control, allowing the motor to rotate in both directions.

- PWM Controllers: Utilize Pulse Width Modulation for efficient speed control, reducing power loss during operation.

- Integrated Circuit Boards: Combine multiple functionalities into a single chip, providing a compact solution for small-scale applications.

- Controller with Feedback Systems: Incorporates sensors to monitor motor performance and adjust control signals for optimal functionality.

Applications of DC Motor Control Boards

The versatility of DC motor control boards allows them to be effectively used in a range of applications, making them an essential component in numerous fields.

- Robotics: Used in robotic automation where precise control and movement of motors are critical.

- Conveyor Systems: Manage motor speeds to ensure smooth operation in material handling processes.

- Automotive: Seen in electric vehicles and other automotive applications for power window operations and electric steering.

- Home Appliances: Integrated into devices such as washing machines and ventilation systems for effective control of motors.

Features and Advantages of DC Motor Control Boards

Investing in a high-quality DC motor control board comes with multiple features and benefits that enhance the performance of DC motors in various applications.

- Efficiency: Designed to optimize power consumption, thereby saving operational costs in the long run.

- Versatility: Compatible with a wide range of DC motors, from small hobbyist models to larger industrial motors.

- Ease of Use: Simplifies the integration of motor control with user-friendly interfaces and setup procedures.

- Robustness: Built to withstand harsh environments, ensuring longevity and reliability in demanding applications.

Function and Design of DC Motor Control Boards

The function and design of DC motor control boards are crucial elements that determine their effectiveness in controlling motor operations.

Most designs focus on providing a compact, stable, and efficient system, featuring:

- Modular Design: Facilitates easy upgrades and replacements, ensuring the board remains adaptable to new technologies.

- Thermal Management: Integrated heat sinks and ventilation can be included to prevent overheating during extended use.

- Multiple Input/Output Interfaces: Support various connecting options for sensors, switches, and other peripherals, enhancing functionality.

- Microcontroller Integration: Many boards will come with advanced processing capabilities, enabling smart functions, such as remote control and automation.