drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

drill pipe price

Types of drill pipes

A drill pipe is a hollow pipe that conveys drilling fluid and other downhole components from the surface to the wellbore to make and maintain drilling for oil and gas. Many factors, such as material, manufacturing method, connection type, and feature, result in variations of drill pipes. Their differences are, however, not limited to those.

- Material: The steel drill pipes(https://www.alabica.com/showProducts/2533.html) are made of steel alloy, which offers increased strength and durability compared with carbon structural steel. Typically, drill pipes consist of a steel pipe body, a steel drill bit, and a steel bit-tie sleeve, which connects the bit to the pipe body.

- Manufacturing method: Drill pipes are manufactured using either the seamless or straight welded method. The advantage of seamless drill pipes is their uniform outer diameter and wall thickness, making consistent quality, while straight welded drill pipes are more affordable because of lower production costs.

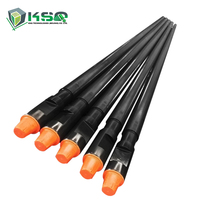

- Connection types: There are different connection types for drill pipes. For example, the API pin and box threads, the AF, and the S-FA are common. The API pin and box threads are classic drill pipe connections. Advanced thread types enhance connection strength and sealing properties.

- Features: Certain properties can vary drill pipes, such as the drill pipe centralizers, which are used to support drill pipes and ensure even fluid distribution during drilling. Also, the drill pipe floats are used to reduce friction between drill pipes and wells, thus facilitating drill pipe movements.

Understanding the various types of drill pipes is critical for selecting the right drill pipes according to specific drilling needs and geological conditions. If retail buyers wish to take their drill pipe business to the next level, knowing the types and features of drill pipes will enable them to choose suppliers and negotiate prices with confidence.

Specification and maintenance

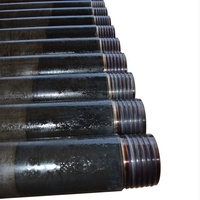

- Length: Drill pipes can come in varying lengths, typically ranging from around 25 feet (7.6 meters) to 40 feet (12.2 meters). Longer drill pipes can get segmented to allow for easy handling.

- Outer diameter: The outer drill pipe diameter will determine the volume of the drilling fluid that circulates during the drilling operation. The outer diameter often ranges from approximately 4.5 inches (11.4 cm) to 10.5 inches (26.7 cm), depending on the type and application of the drill pipe.

- Inner diameter: The inner diameter, or the size of the hole, in the drill pipe allows for the flow of drilling fluids. The inner diameter is smaller than the outer diameter. For instance, a drill pipe with an outer diameter of 4.5 inches has an inner diameter of about 3.91 inches.

- Weight: Drill pipes are heavy due to their size and materials. A drill pipe can weigh anywhere from 11.6 pounds per foot to over 30 pounds per foot, depending on the dimensions and grade.

Maintaining drill pipes is crucial for their longevity, performance, and safety during drilling operations. Here's a brief overview of some maintenance practices for drill pipes:

- Regular inspection: Conduct routine visual and equipment inspections to check for signs of wear, damage, or corrosion. This helps operators discover any potential issues early to address them before they become more serious problems.

- Cleaning: Regularly clean drill pipes to remove any buildup of drilling mud, fluid, scale, or debris. Ultrasonic cleaning or high-pressure water jet cleaning can be effective methods. Cleaning helps prevent pipe clogging, reduces corrosion rates, and makes thread connections better.

- Thread repair: Damaged or worn drill pipe threads can negatively impact connections. Consequently, users should have them repaired by experienced professionals using appropriate thread repair equipment. This ensures the threads are properly restored for reliable connections.

- Pipe management systems: Using pipe management systems helps organize and segregate drill pipes based on their usage and condition. Such management systems prevent mixing of drill pipe sections with different thread types or strain configurations so that operators can easily track the status of each drill pipe section.

- Drill pipe storage: When not in use, properly store drill pipes in vertical racks or stands. Storing them this way avoids bending, warping, and damage to the drill pipes.

Scenarios

The usage of drill pipes is mainly concentrated around the mining and oil and gas industry, but they are also found in the following industries and applications.

-

Construction Industry

-

Geothermal Drilling

-

Horizontal Directional Drilling (HDD)

-

Water Well Drilling

-

Soil Sampling and Testing

-

Oil Sands Extraction

-

Underwater Drilling

The construction industry uses drill pipes for foundation drilling and building pile construction. The drill pipes help create deep vertical holes.

Drill pipes are instrumental in geothermal drilling. They help create holes to access geothermal reservoirs for designing reliable energy systems.

Drill pipes are the backbone of HDD, a trenchless technology for laying pipelines and cables. The drill pipes allow curved and horizontal drilling under obstacles like roads and rivers.

Water drill pipes serve the same purpose as oil drill pipes, but they are designed with corrosion-resistant materials to withstand the effects of chemicals present in ground water. They are also equipped with valves and pumps to facilitate the flow of water during the drilling process.

In environmental investigations and geotechnical engineering, drill pipes are used for soil sampling and testing. They help collect soil samples in boreholes to analyze the ground conditions.

In oil sands deposits, drill pipes also play a key role in the extraction process. These drill pipes are used for in-situ recovery or to create vertical wells for oil sands mining.

Underwater or subsea drilling, involves using drill pipes to carry the drilling rig and equipment from the surface to the seabed, where exploration and extraction take place.

Drilling is done through a large diameter pipe called a riser, which keeps the equipment and crew dry and safe. Click here to learn more about drill pipe.

How to choose drill pipe prices

There are many types of drill pipes available, and it may be easy to gloss over some attributes because drill pipe price is the main focus. However, when purchasing drill pipes, especially in bulk, for resale or use in an oil drilling business, businesses need to look beyond the price and inspect the quality.

With the growing interest in shale oil and tight gas formations, understanding how the choice of rock impacts the selection of drill pipes has become very important in the drilling industry. In drill pipe selection, the strata the drill pipe will be used for need to be of primary concern. If the formation has not been encountered before, it may be useful to consult experts and use their knowledge to estimate what drill pipes should be used.

The drill pipe's wall thickness should also be considered in light of the type of soil or rock to be drilled. If a lot of drill pipes are being purchased, it may be useful to survey the local geology and then decide on the quantity and thickness of the drill pipes required to carry out drilling operations efficiently.

Know how the drill pipes transport drilling fluid and the quantity of air or fluid that is needed should also be considered to ensure that there won't be any delays or problems when drilling takes place. While high-quality drill pipes with alloy steel are built to last, they will need to be replaced at some point. Set a timeline on when they are expected to be replaced, based on the local geology and the drilling rate. If this is known, then it will make it easy to determine what price range should be looked at when purchasing drill pipes in bulk.

Finally, suppliers and buyers should communicate closely, so there are no surprises on either side when the order is delivered. Is there a need for a secondary inspection facility at the supplier's end? This should be considered in light of the overall budget and amount ordered. Using these methods will help buyers know exactly how many drill pipes are required, their prices, and their quality.

Drill pipe price Q & A

Q: What is the main factor that affects the drill pipe prices?

A: Material is the main factor that affects drill pipe prices. Drill pipes are typically manufactured using high-strength alloy steel and may undergo specific heat treatment processes to boost their longevity and durability. Additionally, some drill pipes may come with anti-abending collars that prevent them from getting easily damaged during the process of drilling.

Q: How does the drill pipe diameter influence drill pipe prices?

A: Drill pipe prices may vary depending on the diameter. Typically, larger drill pipes require more material costs and manufacturing efforts, which leads to a higher price. On the other hand, small-diameter drill pipes are more affordable, but their prices may rise depending on demand.

Q: Why do used drill pipes have different prices?

A: The used drill pipe price is largely determined by its condition. In this case, if a drill pipe is slightly worn out and doesn't require major repairs, it fetches a higher price. More, the market demand and supply also influence used drill pipes prices. When the demand is high, prices are likely to increase. Also, if the supply is low, prices may go up and vice versa.

Q: What is the joint type, and how does it affect the price of the drill pipe?

A: The drill pipe's joint types are generally priced differently. Drill pipes with traditional upset, external upset, or rotary shouldered joints may have slightly lower prices. Drill pipes with effective stiff joints like non-magnetic drill pipes may have higher prices due to their effective transmission of torque and higher handling costs during the assembly process.