dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

dust filter

The Machinery Industry and Dust Filters

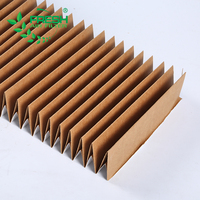

In the vast machinery industry, dust filters play a crucial role in ensuring the efficiency and longevity of various equipment and machinery. A dust filter is designed to remove particulate matter from the air or gas stream, preventing contamination and maintaining a clean working environment. These filters are essential for industries such as manufacturing, construction, mining, and agriculture where dust and particles are common byproducts of operations.

Types of Dust Filters

There are several types of dust filters available in the market, each designed for specific applications and environments. Some common types include bag filters, cartridge filters, cyclone separators, electrostatic precipitators, and HEPA filters. Bag filters are suitable for capturing large particles, while HEPA filters are highly efficient in removing fine particles, making them ideal for industries with strict cleanliness requirements.

Technical Specifications and Features

When selecting a dust filter for your machinery or industrial application, it is essential to consider the technical specifications and features that best suit your needs. Factors such as filtration efficiency, airflow capacity, pressure drop, filter media type, and maintenance requirements are critical in determining the effectiveness of the filter. For example, a high-efficiency particulate air (HEPA) filter can capture 99.97% of particles as small as 0.3 microns.

Advantages of Using Dust Filters

The benefits of incorporating dust filters into your machinery or industrial processes are manifold. By effectively removing dust and contaminants from the air or gas stream, these filters help improve air quality, protect equipment from damage and wear, reduce maintenance costs, and enhance overall productivity. Additionally, using dust filters can contribute to a safer and healthier work environment for employees.

Choosing the Right Dust Filter

When choosing a dust filter for your specific application, it is essential to assess your filtration needs, environmental conditions, space constraints, and budget considerations. Consulting with industry experts or suppliers can help you determine the most suitable filter for your machinery or equipment. Consider factors such as filter efficiency, airflow capacity, filter size, and maintenance requirements to make an informed decision.

Maintenance and Care Tips

Proper maintenance of dust filters is crucial to ensure their optimal performance and longevity. Regular inspection, cleaning, and replacement of filter elements are necessary to prevent clogging, maintain airflow efficiency, and uphold air quality standards. Following the manufacturer's guidelines for maintenance and care can help extend the life of the filter and maximize its effectiveness in controlling dust and particles.

Conclusion

In conclusion, dust filters are indispensable components in the machinery industry, playing a vital role in maintaining clean and healthy work environments, protecting equipment, and enhancing overall productivity. By understanding the different types, technical specifications, advantages, and maintenance requirements of dust filters, businesses can make informed decisions to select the most suitable filters for their machinery and industrial applications.